CRANKSHAFT

Clean

crankshaft thoroughly

and

inspect journals

for

scoring, chipping, cracking, or signs

of

overheating.

If

crankshaft has overheated, is scored, or excessively

worn, reconditioning

or

replacement will be required.

Examine bearing journals for cracks

if

overheating has

occurred.

L

I

Measure crankshaft main bearing and connecting rod

journals at several places on their diameter to check for

roundness and taper.

The only recommended method of reconditioning the

crankshaft

is

regrinding, as required to accommodate

undersize bearings. Metallizing

of

bearing journals is

not recommended.

If

regrinding of crankshaft journals is necessary, the

work should be done by a reputable machine shop that

has suitable equipment to handle precision work

of

this

type. Undersize main bearings are available in sizes of

0.01

0,

0.020,

and

0.030

inch. Undersize connecting

rods are available in sizes of

0.010,

0.020,

0.030

and

0.040

inch.

Whenever making major repairs on the engine, always

inspect the drilled passages

of

the crankshaft. Clean

them to remove any foreign material and

to

assure

proper lubrication

of

the connecting rods.

BEARINGS

With camshaft and crankshaft removed, use a micro-

meter

to

measure diameter

of

bearing journals. Use a

dial bore gauge

or

a telescopic gauge and micrometer

to measure inside diameter of bearings. Refer to

DIMENSIONS AND CLEARANCES

to determine

if

clearances are within specifications.

Any bearing that is scored, chipped, pitted or worn

beyond the specified limits must be replaced.

Removal

of

the camshaft bearings requires complete

disassembly of the engine. Use a press or a suitable

driver to remove bearings.

Support casting to avoid

distortion and to avoid damaging the bearing bore

during removal and installation.

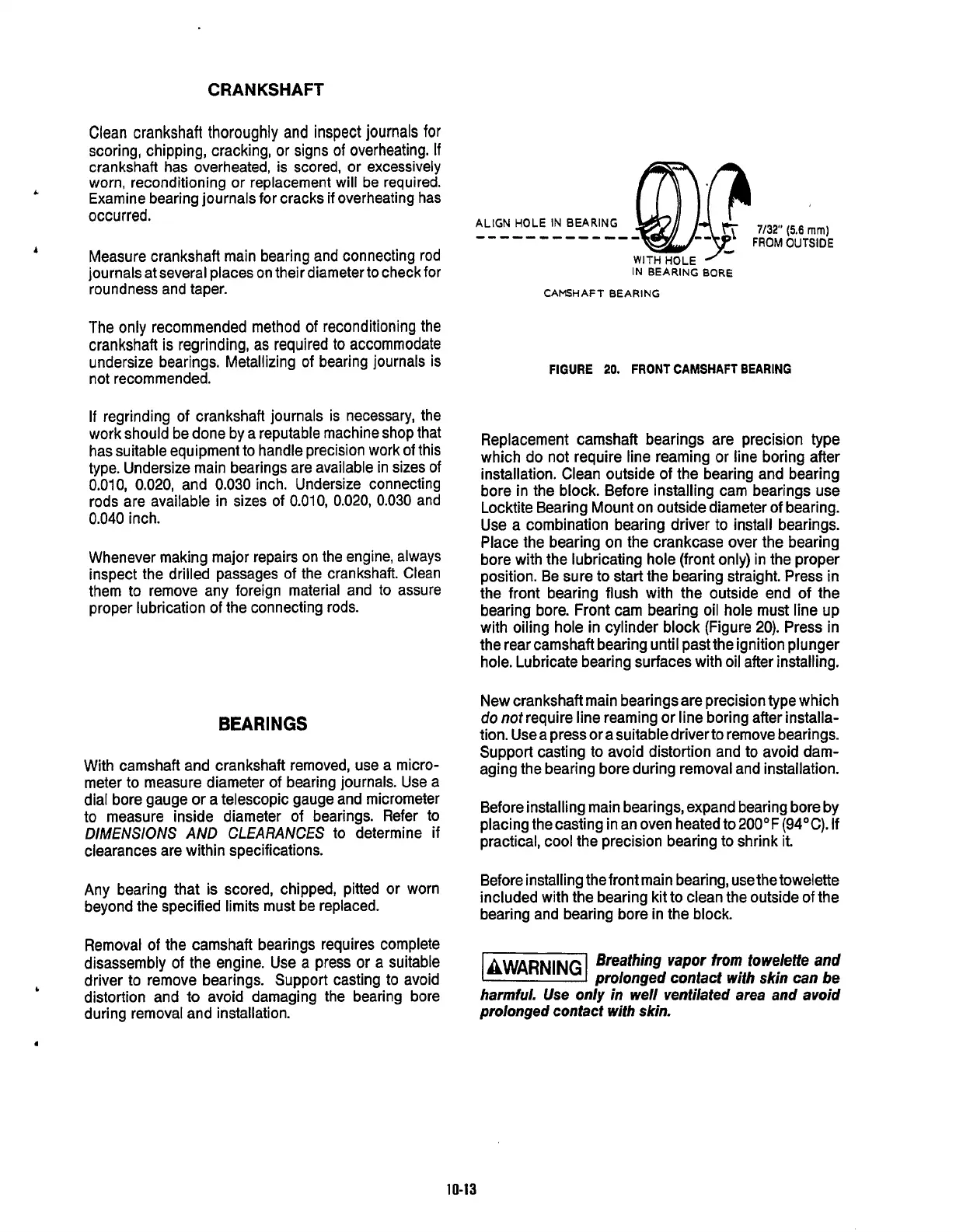

C

7/32'

(5.6

mm)

FROM

OUTSIDE

ALIGN

HOLE IN

BEARING

-------------

IN

BEARING BORE

CAWSHAFT BEARING

FIGURE

20.

FRONT

CAMSHAFT

BEARING

Replacement camshaft bearings are precision type

which do not require line reaming or line boring after

installation. Clean outside of the bearing and bearing

bore in the block. Before installing cam bearings use

Locktite Bearing Mount on outside diameter of bearing.

Use a combination bearing driver to install bearings.

Place the bearing on the crankcase over the bearing

bore with the lubricating hole (front only) in the proper

position. Be sure to start the bearing straight. Press in

the front bearing flush with the outside end of the

bearing bore. Front cam bearing oil hole must line up

with oiling hole in cylinder block (Figure

20).

Press in

the rear camshaft bearing until past the ignition plunger

hole. Lubricate bearing surfaces with oil after installing.

New crankshaft main bearings are precision type which

do

not

require line reaming or line boring after installa-

tion. Usea press ora suitable driverto remove bearings.

Support casting to avoid distortion and to avoid dam-

aging the bearing bore during removal and installation.

Before installing main bearings, expand bearing bore by

placing the casting in an oven heated to 200°F

(94OC).

If

practical, cool the precision bearing to shrink

it.

Before installing the front main bearing, usethe towelette

included with the bearing kit to clean the outside of the

bearing and bearing bore in the block.

Breathing

vapor

from

fowelefte

and

prolonged confacf with

skin

can be

harmful. Use only in well ventilated area and avoid

prolonged contact

with

skin.

10-13

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...