OIL FILTER CHANGE

Refer to Periodic Maintenance Schedule, located in the

Operator’s Manual, for

oil

filter change interval.

If

operating in extremely dusty, high ambient, or low

ambient conditions change oil more often.

Spin

off

oil filter element and discard

it.

Thoroughly

clean filter mounting surface and install new element,

making sure new gasket is inserted in the element.

Apply a thin film of

oil

to the gasket. Spin element down

by hand until gasket just touches mounting pad and

then turn down an additional

1/2-3/4

turn.

Do

not

overtighten.

With oil in crankcase, start engine and check for leaks

around filter element. Retighten only as much as

necessary to eliminate leaks; do not overtighten.

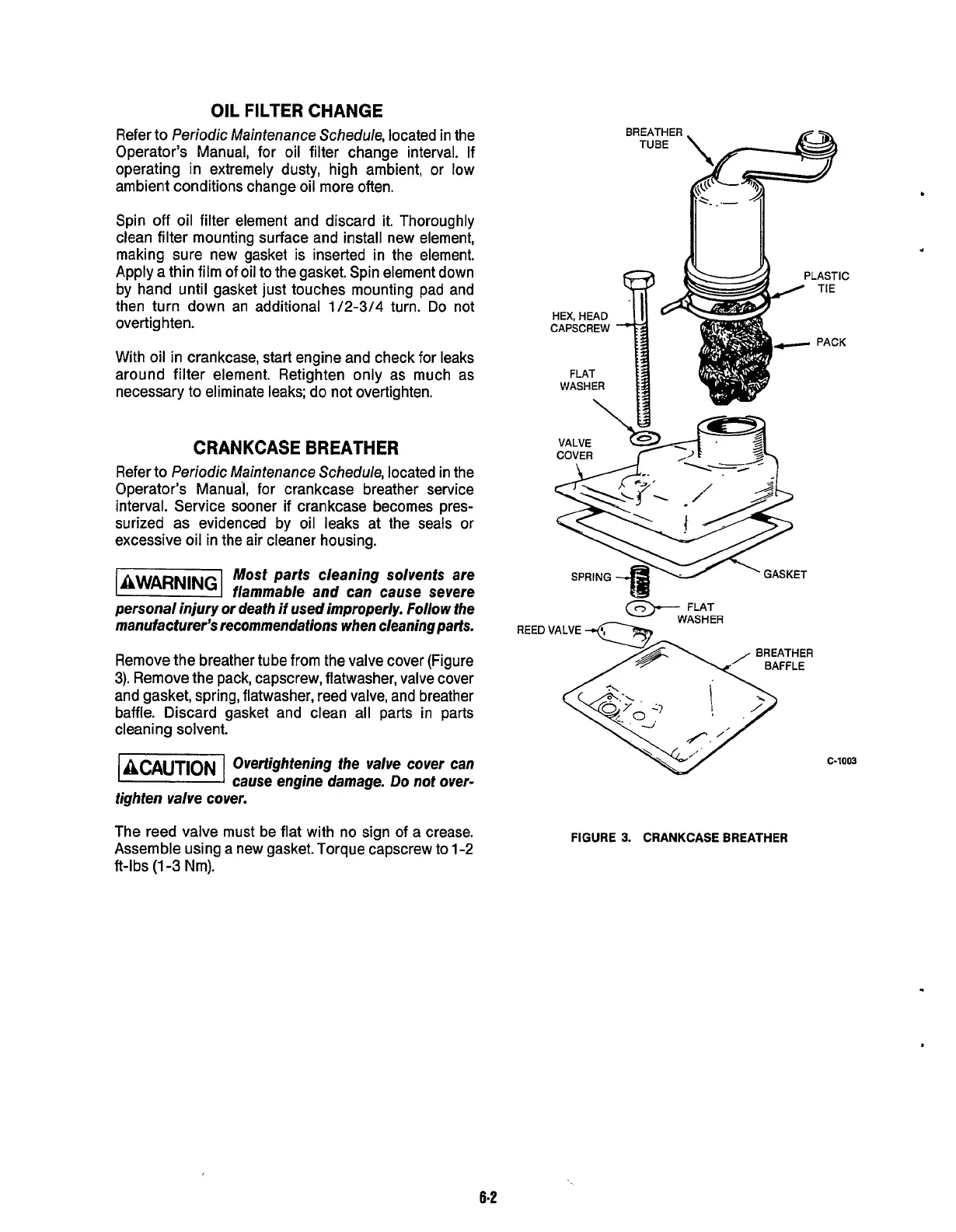

CRANKCASEBREATHER

Refer to Periodic Maintenance Schedule, located in the

Operator’s Manual, for crankcase breather service

interval. Service sooner

if

crankcase becomes pres-

surized as evidenced by oil leaks at the seals or

excessive oil in the air cleaner housing.

Most parts cleaning solvents are

flammable and can cause severe

personal injury

or

death if used improperly. Follow the

manufacturer’s recommendations when cleaning parts.

Remove the breather tube from the valve cover (Figure

3).

Remove the pack, capscrew, flatwasher, valve cover

and gasket, spring, flatwasher, reed valve, and breather

baffle. Discard gasket and clean all parts in parts

cleaning solvent.

=

cause engine damage.

Do

not over-

tighten

valve cover.

ACAUTlON

Overtightening the valve cover can

c-low

.

FIGURE

3.

CRANKCASE BREATHER

The reed valve must be flat with no sign of a crease.

Assemble using a new gasket. Torque capscrew to

1-2

ft-lbs

(1

-3

Nm).

6-2

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...