60

If the contact is uneven, replace the valve guide.

Width of inlet and exhaust valve sealing surface: 0.9~1.1mm

Trim the valve seat ring

1. Trim the valve with a 45° valve seat ring cutter and adjust the width of the sealing

surface.

Turn the cutter clockwise until the surface of the seat ring is smooth.

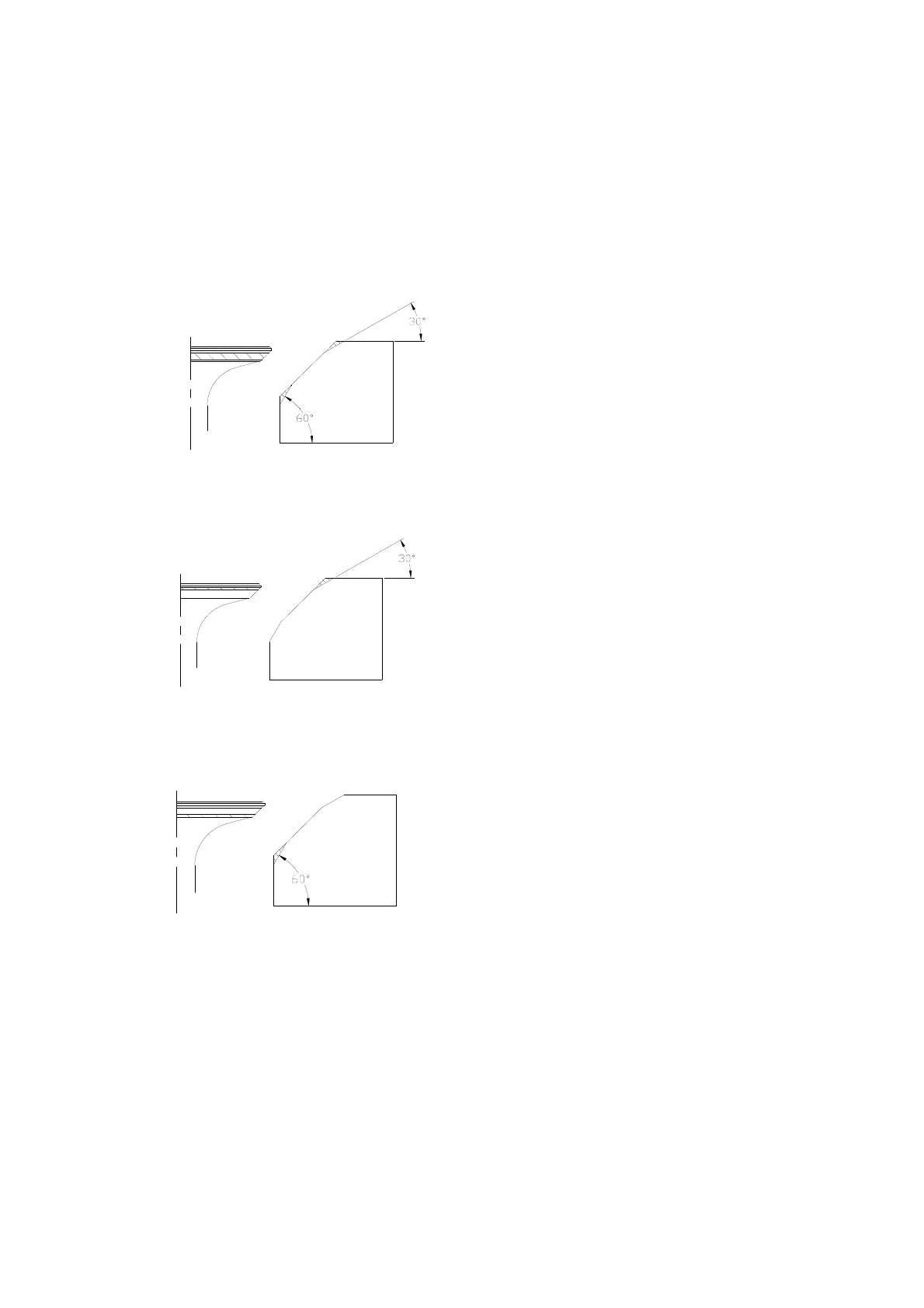

2. If the valve sealing surface is too wide and in the middle of the valve surface, trim the

top edge of the seat ring with a 30° cutter and the bottom edge of the seat ring with a 60° cutter

and adjust the width of the sealing surface.

3. If the valve sealing surface is too narrow and at the top edge of the valve surface, trim

the top edge of the seat ring with a 30° cutter, if so, adjust the width of the sealing surface with a

45° cutter.

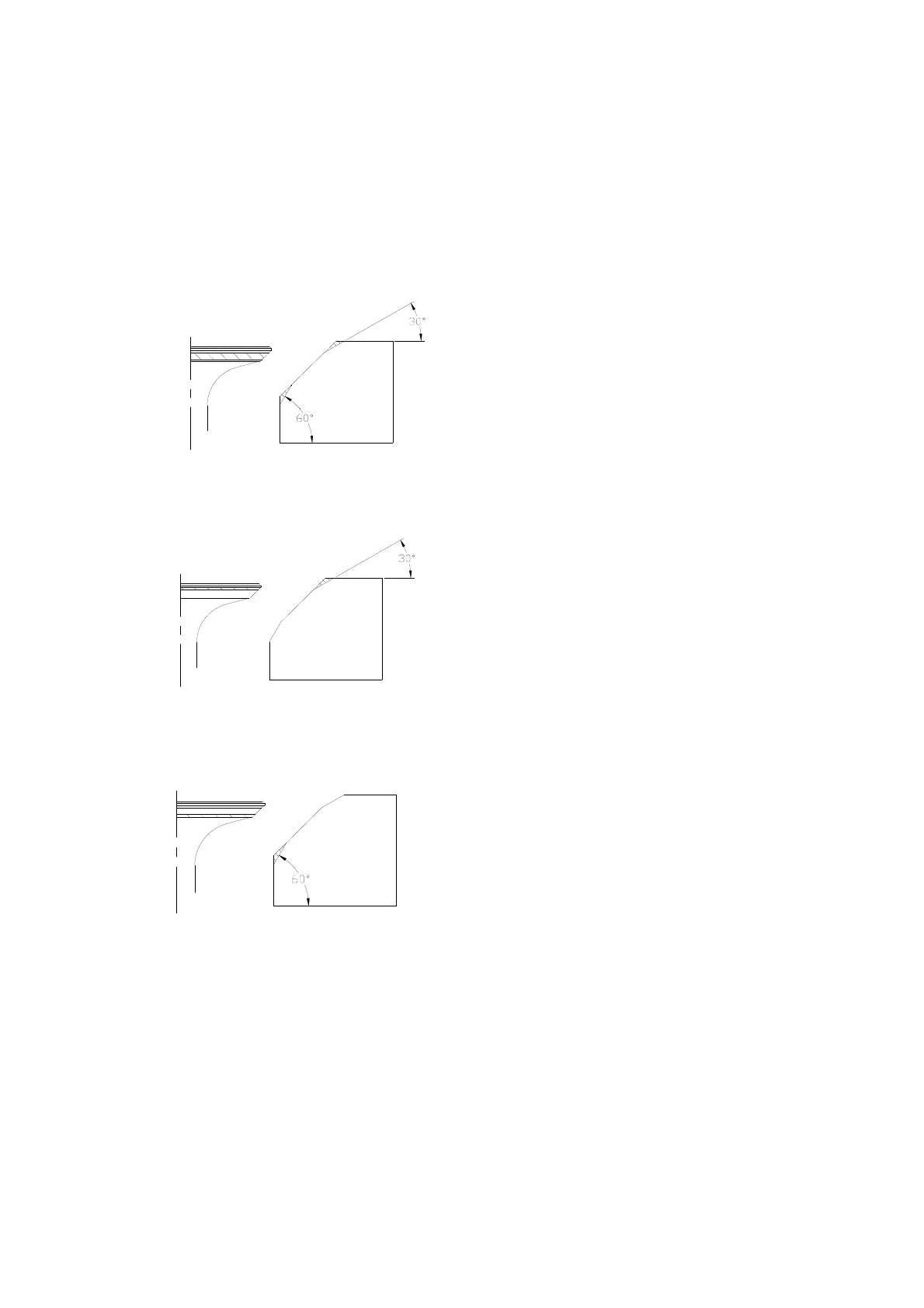

4. If the valve sealing surface is too narrow and at the bottom edge of the valve surface,

trim the bottom edge of the seat ring with a 60° cutter, and if so, adjust the width of the sealing

surface with a 45° cutter.

5. Apply a thin layer of abrasive evenly on the valve seat ring and grind the valve with a

valve grinding tool.

6. Remove the residual abrasive.

7. Check the valve sealing surface width again.

Attention:

Don't cut the valve too much, turn the cutter evenly with a downward force of 40 ~ 50N.

Do not attach the abrasive to the valve stem and valve guide.

Loading...

Loading...