105

Pinion Shim

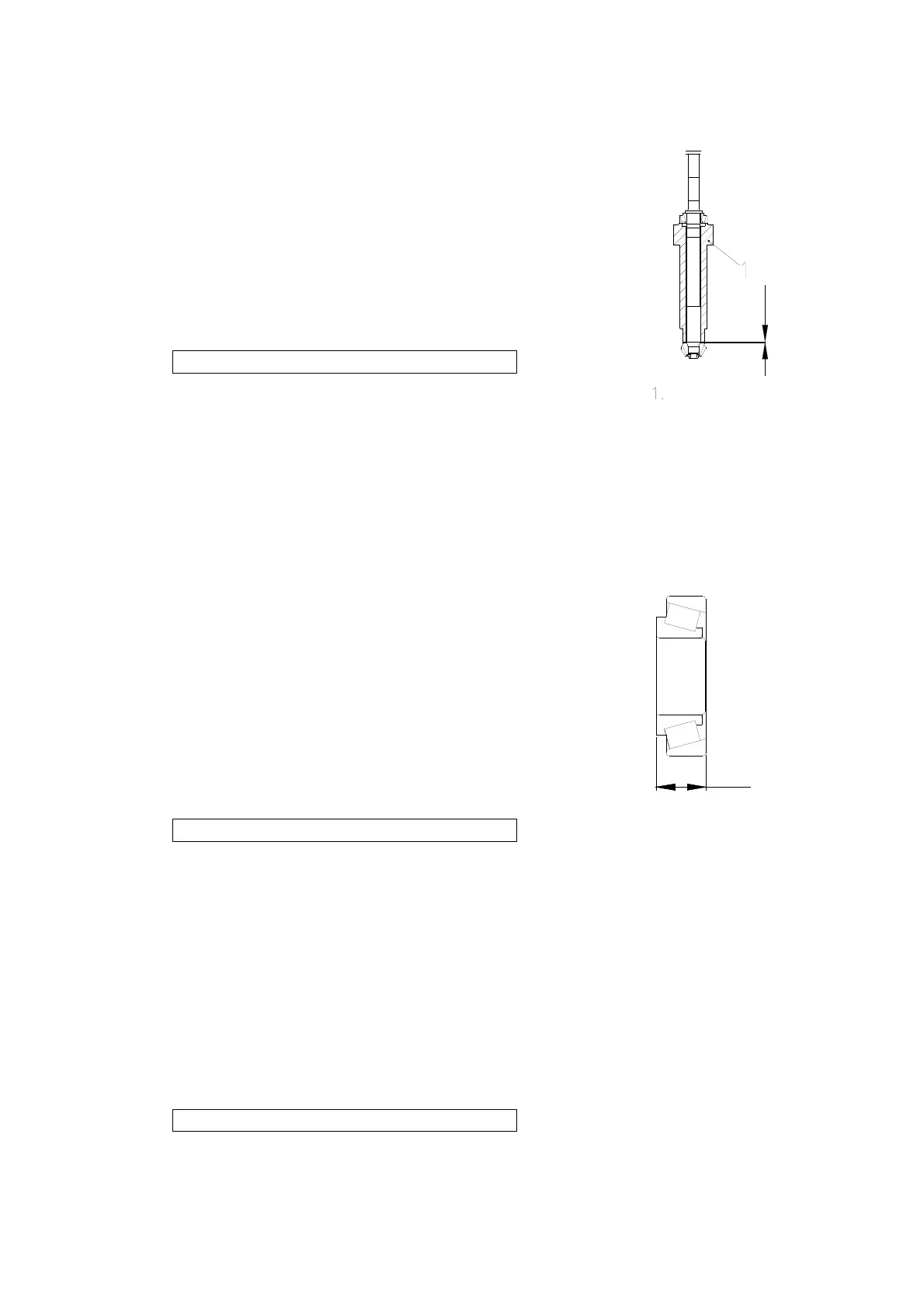

1. Check the P value engraved on the Lower casing unit.

2. Attach the drive shaft to the special tool. Fit the pinion and lock the pinion nut

according to the specified torque.

Specified torque: 95 Nm

3. Measure the clearance between the special tool and

the pinion with a gauge,

Calculate the thickness T3 according to the formula.

Formula: T3=M3-(P/100)

Formula for CD/CT: T3=M3-(P/100)+0.1

4. Shims that can be selected.

0.10, 0.12, 0.15, 0.18, 0.3, 0.4, 0.5 mm

Note:

The thickness of the shim can be 0 ~ 0.05

thicker than T3, and the closest size is selected.

Shims for Forward Gear

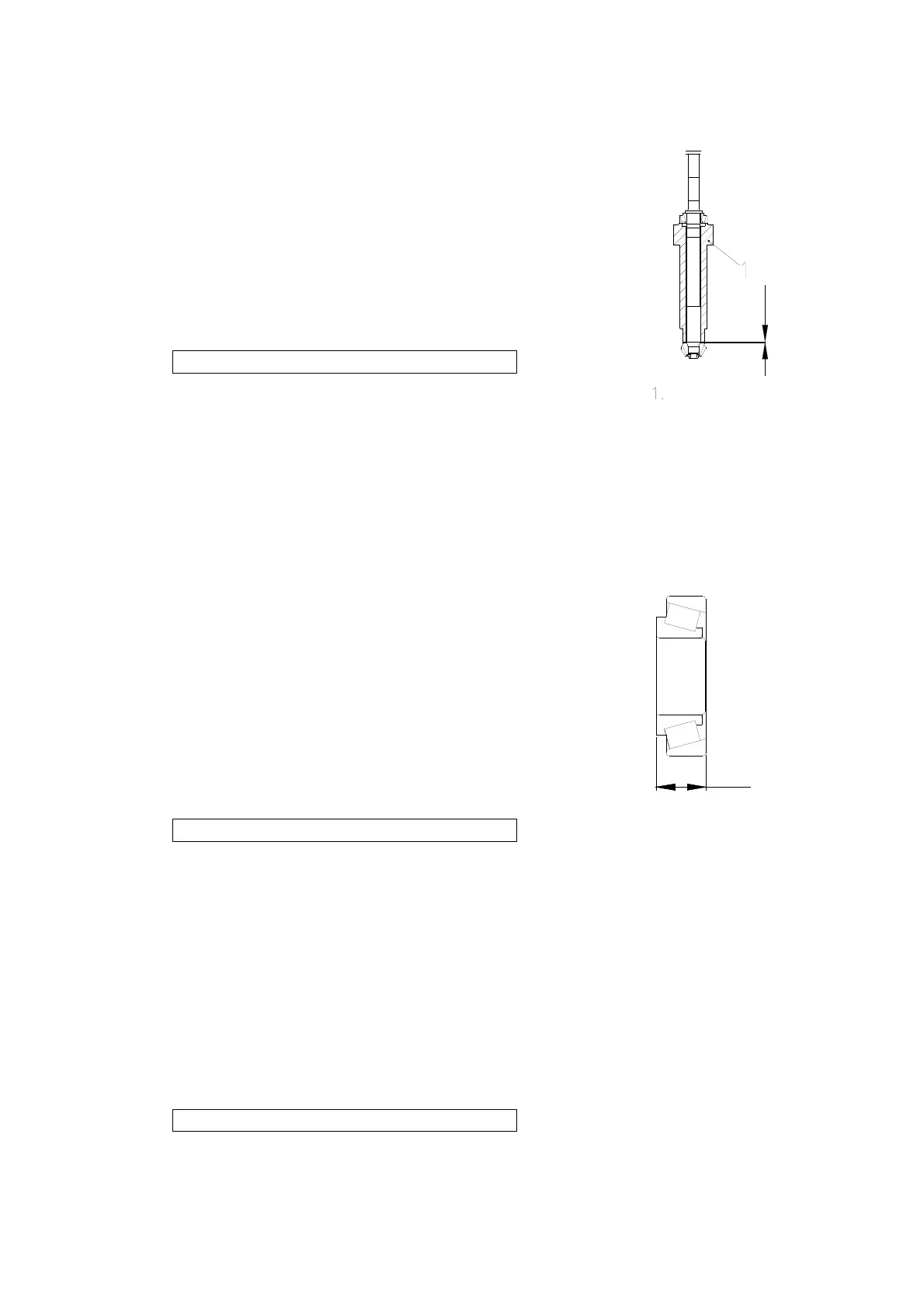

1. Check the F value engraved on the Lower casing unit.

2. Turn the outer ring of the forward gear bearing so that the roller falls completely into

the bearing casing.

3. Measure the bearing height and calculate the thickness T1

according to the formula.

Formula: T1=26.70+(F/100)-M1

Formula for CD/CT: T1=24.2+(F/100)-M1

Note:

When measuring the thickness, it is measured at 3 points.

Average the results.

4. Shims that can be selected.

0.10, 0.12, 0.15, 0.18, 0.3, 0.4, 0.5 mm

Note:

The thickness of the shim can be 0 ~ 0.05 thinner than T1, and the closest size is

selected.

Shims for Reverse Gear

1. Check the R value engraved on the Lower casing unit.

2. Formula: T2=0.5+(R/100)

Formula for CD/CT: T2=0.5-(R/100)

3. Shims that can be selected.

0.10, 0.12, 0.15, 0.18, 0.3, 0.4, 0.5 mm

Note:

The thickness of the shim can be 0 ~ 0.05 thinner than T2, and the closest size is selected.

For CD/CT, the thickness of the shim can be 0 ~ 0.05 thicker than T2, and the closest size is selected.

M3

专用工具

M1

Loading...

Loading...