Revision 3 | Granolyser / Granolyser HL operating instructions

8.1.3 Printer

CAUTION

Burns of hands and fingers!

The print head becomes very hot during operation!

Allow the print head to cool sufficiently before cleaning.

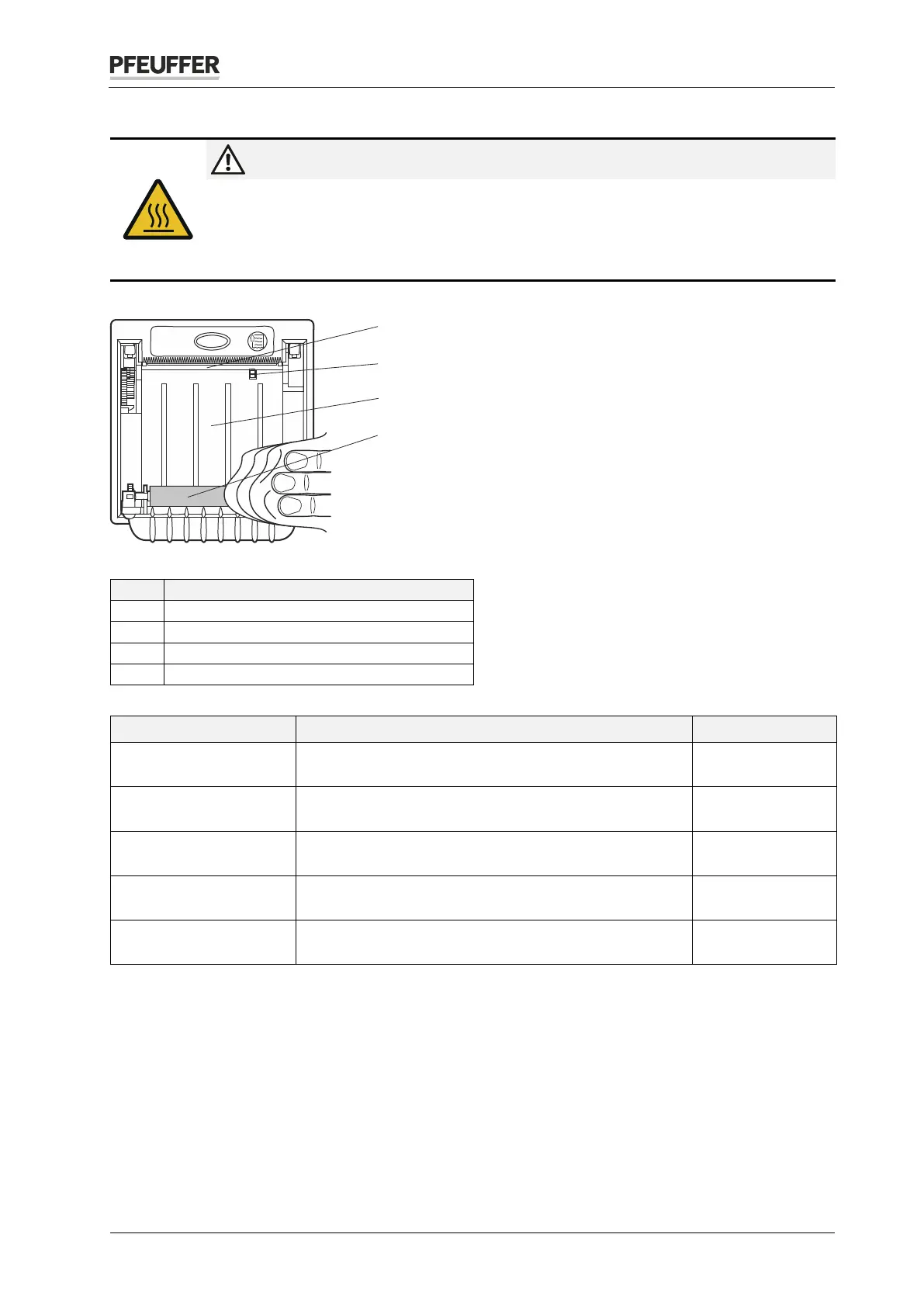

Figure 8: Clean the printer

Cleaning Rectification Interval

Print head

With a clean, dry and lint-free cloth.

If required cloth moistened with isopropanol.

Print roller

With a clean, dry and lint-free cloth.

If required cloth moistened with isopropanol.

Paper detection sensor With compressed air (spray can)

After every fifth

paper change

Paper compartment With compressed air (spray can)

After every fifth

paper change

Housing With compressed air (spray can) or a soft cloth. As required

8.2 Maintenance

Maintenance is a part of servicing and refers to the scheduled cleaning, checking and replacement of

wearing parts. The aim of maintenance is to maintain the full functionality of the instrument over its

lifetime.

The

GRANOLYSER should therefore be checked for wear and tear at regular intervals. The inspection

intervals depend on the frequency of use and the ambient conditions to which the

GRANOLYSER is exposed.

Only through regular checks (visual inspection) can damage to the instrument caused during use be

detected early and reliably.

If you are unsure whether your instrument is still completely ready for use, Pfeuffer GmbH's professional

service team will be pleased to assist you.

Loading...

Loading...