© PSI (Photon Systems Instruments), spol. s r. o.

24

Important: It is necessary to allow 20 minutes stabilization time for the device prior any experiment

or calibration is performed. This stabilization time is required for temperature stabilization of the

measuring system.

Important: It is strongly recommended to use back-up UPS system to protect the PBR FMT150 system

from power outage. If UPS system is not used and the AC power is turned off unexpectedly the PBR

FMT150.1 control unit needs to be switched ON with the MAINS key. After switching the unit ON, all

previous settings will be reset. Please note that if PBR software is used and the power outage occurred

all previous settings will be restored and the currently running experiments will continue.

In case of the PBR FMT150.2, control unit will automatically switch ON after the AC power is restored

again and no manual action is required.

4.2 CULTIVATION VESSEL

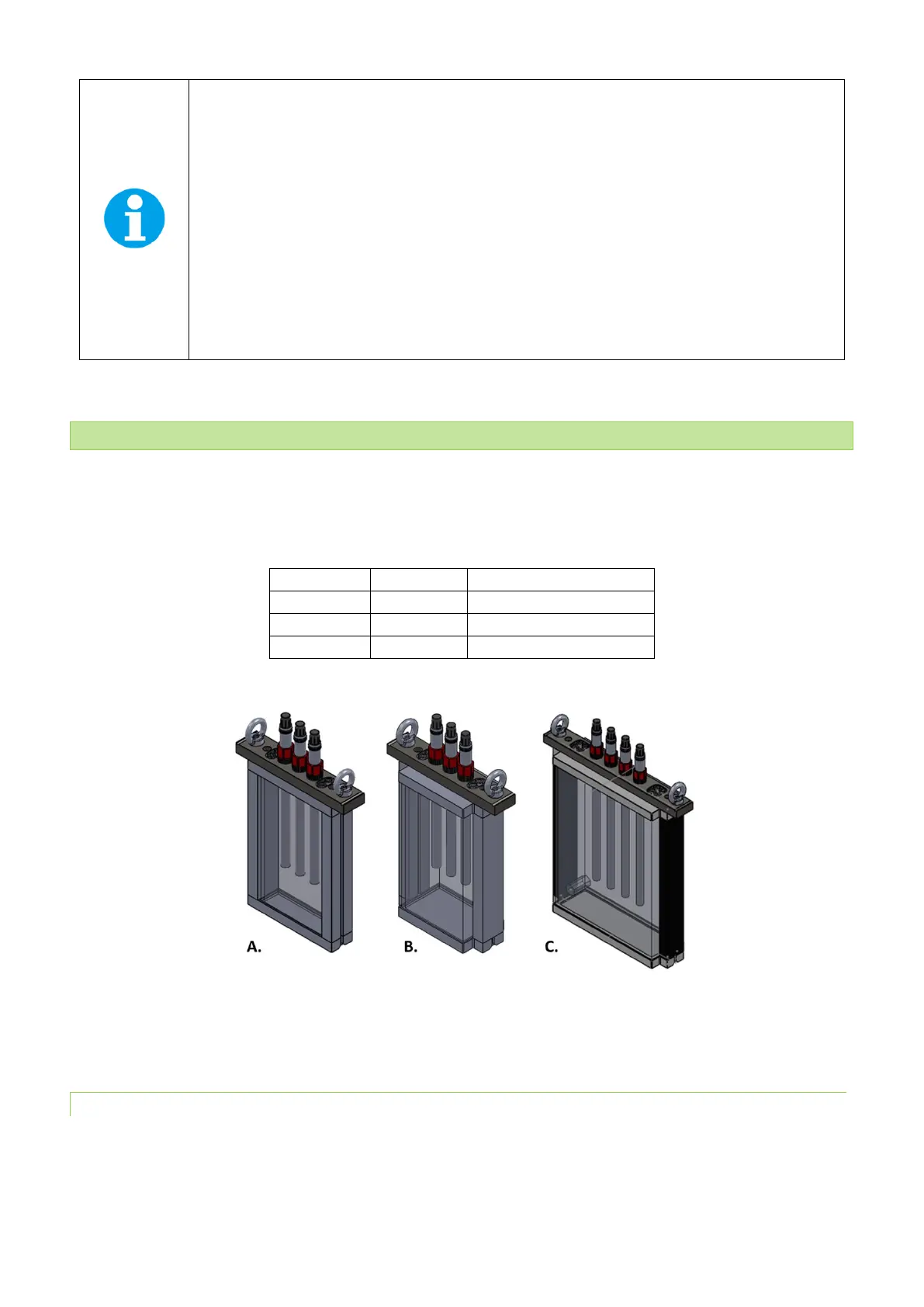

The standard cultivation vessel has capacity of 400 ml, 1000 ml or 3000 ml (depending on the unit ordered). It is made

from flame-proof glass (thickness 3.3 mm), stainless steel (AISI316L), duralumin with black eloxal coating, silicone sealing,

and Lukopren S6410T glue. Each vessel is tested and autoclaved (20 minutes at 120 °C) by the manufacturer before

distribution.

Tab. 6 Weights and dimensions.

Fig. 12 Schematic design of the PBR cultivation vessel types. A) Vessel for PBR FMT150/400. B) Vessel for PBR FMT150/1000. C) Vessel

for PBR FMT150/3000.

4.2.1 SETUP

The lid of the vessel is fastened to the vessel via two screws (n°3 in Fig. 13C) using the hex key provided. The lid has two

holders built in for easy handling of the vessel in and out of the photobioreactor (n°2 Fig. 13C). There are four openings for

luer connectors. These are used for connection of aeration tubing, sampling tubing and waste expel tubing (Fig. 13B). The

Loading...

Loading...