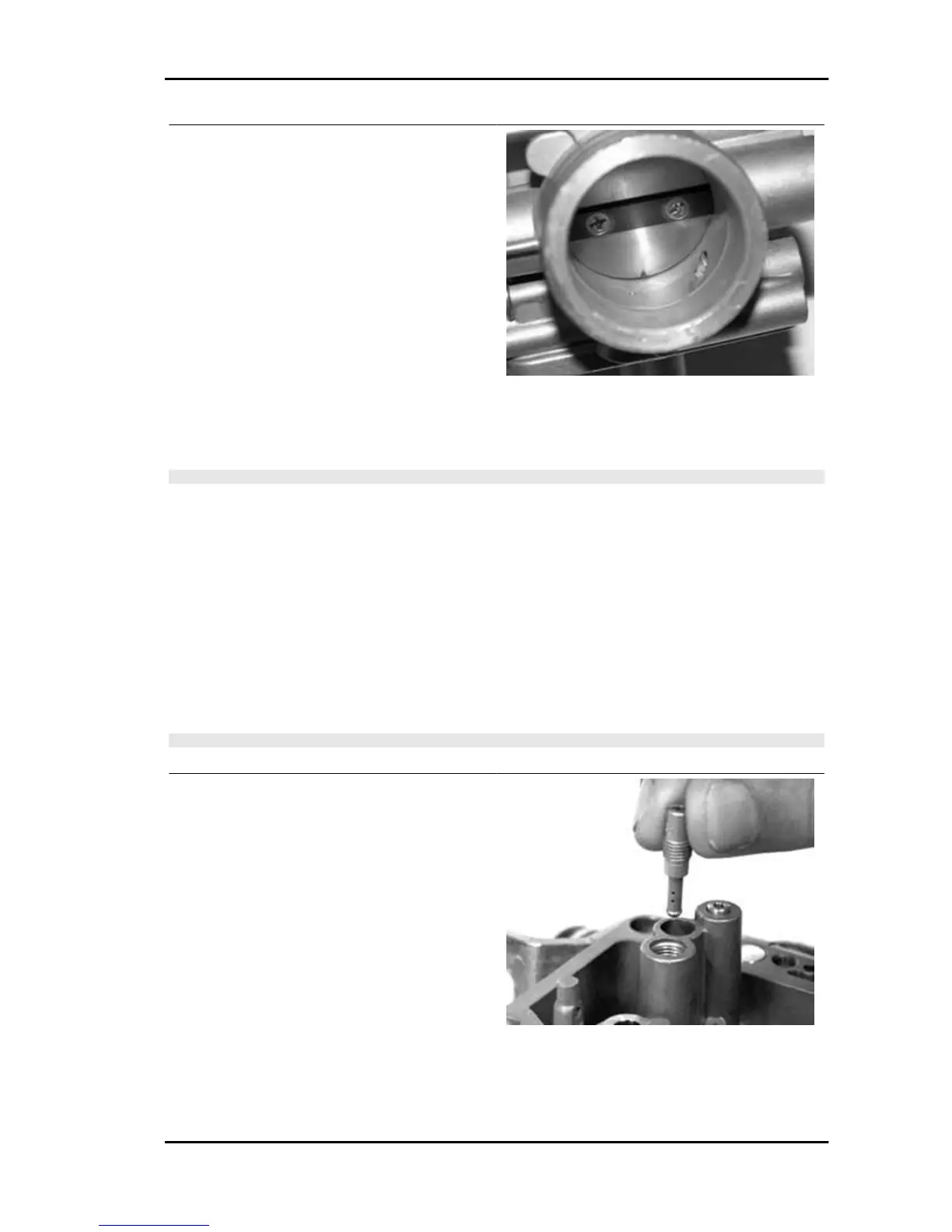

- For the minimum circuit, make sure the following

points are properly cleaned: air gauging, outlet

section controlled by flow screw, progression

holes near the throttle valve.

- For the starter circuit, blow the connection pipe properly with the jet. This is necessary because the

nozzle support hides other inaccessible internal calibrations.

- Blow the intake nozzle properly.

N.B.

THE ACCELERATION NOZZLE OUTLET IS EXTREMELY SMALL AND IS ORIENTED TO THE

THROTTLE VALVE. NOZZLE INCORRECT ORIENTATION RESULTS IN INADEQUATE SPRAY-

ING.

- Check that there are 5 closing ball joints for the operating pipes on the carburettor body.

- Check that the coupling surfaces, the tank and the diaphragm are not dented.

-Check that the depression valve housing pipe is not scratched.

- Check that the throttle valve and the shaft do not show abnormal wear.

- Check that the plunger seat does not show abnormal wear.

- Replace the carburettor in case of irregularities.

- Check that the return spring of the accelerating pump rocking lever is not deformed by over-stretching.

N.B.

TO AVOID DAMAGES, DO NOT INTRODUCE METAL OBJECTS IN THE ADJUSTED SECTIONS.

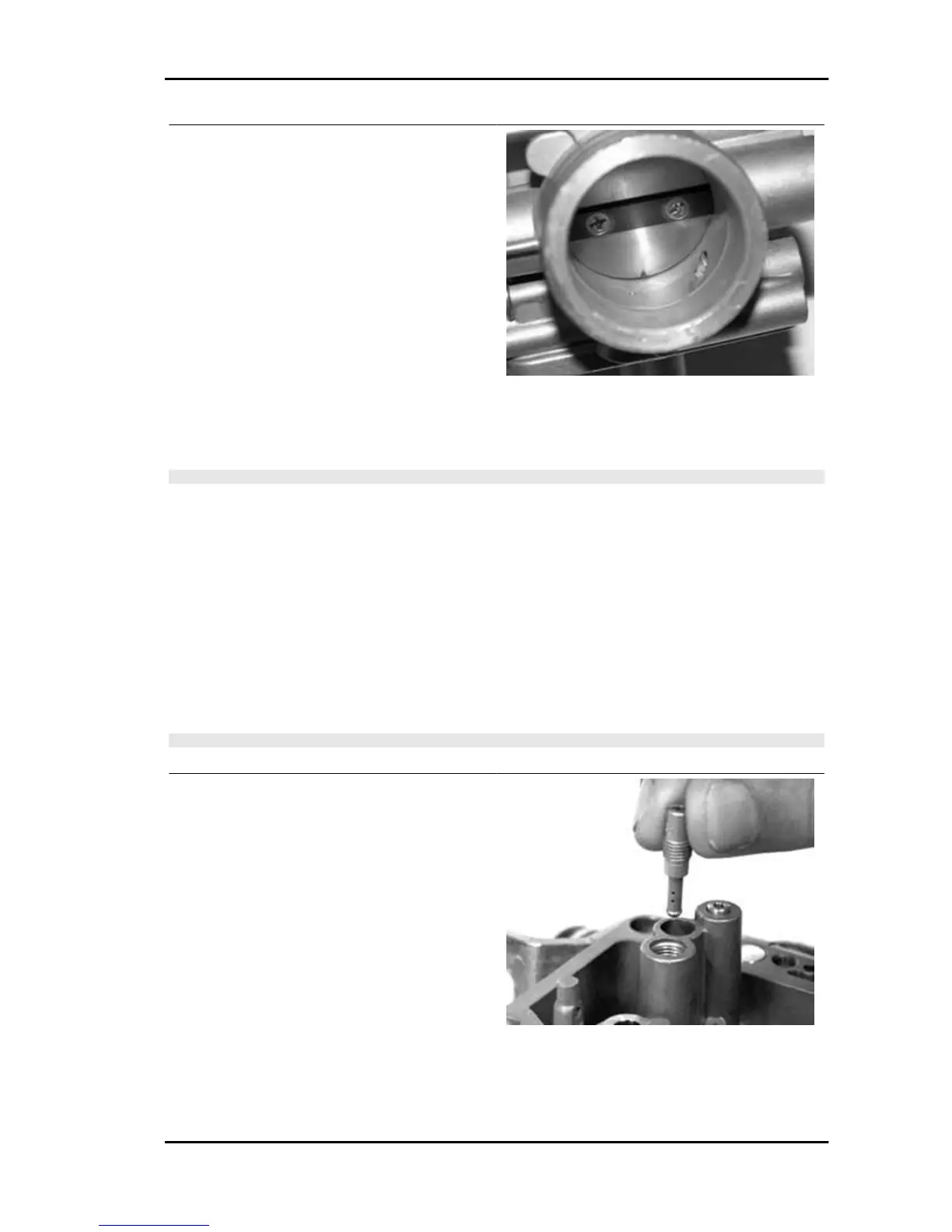

- Wash and blow the minimum nozzle properly and

reassemble it.

Runner 125 - 200 Engine

ENG - 201

Loading...

Loading...