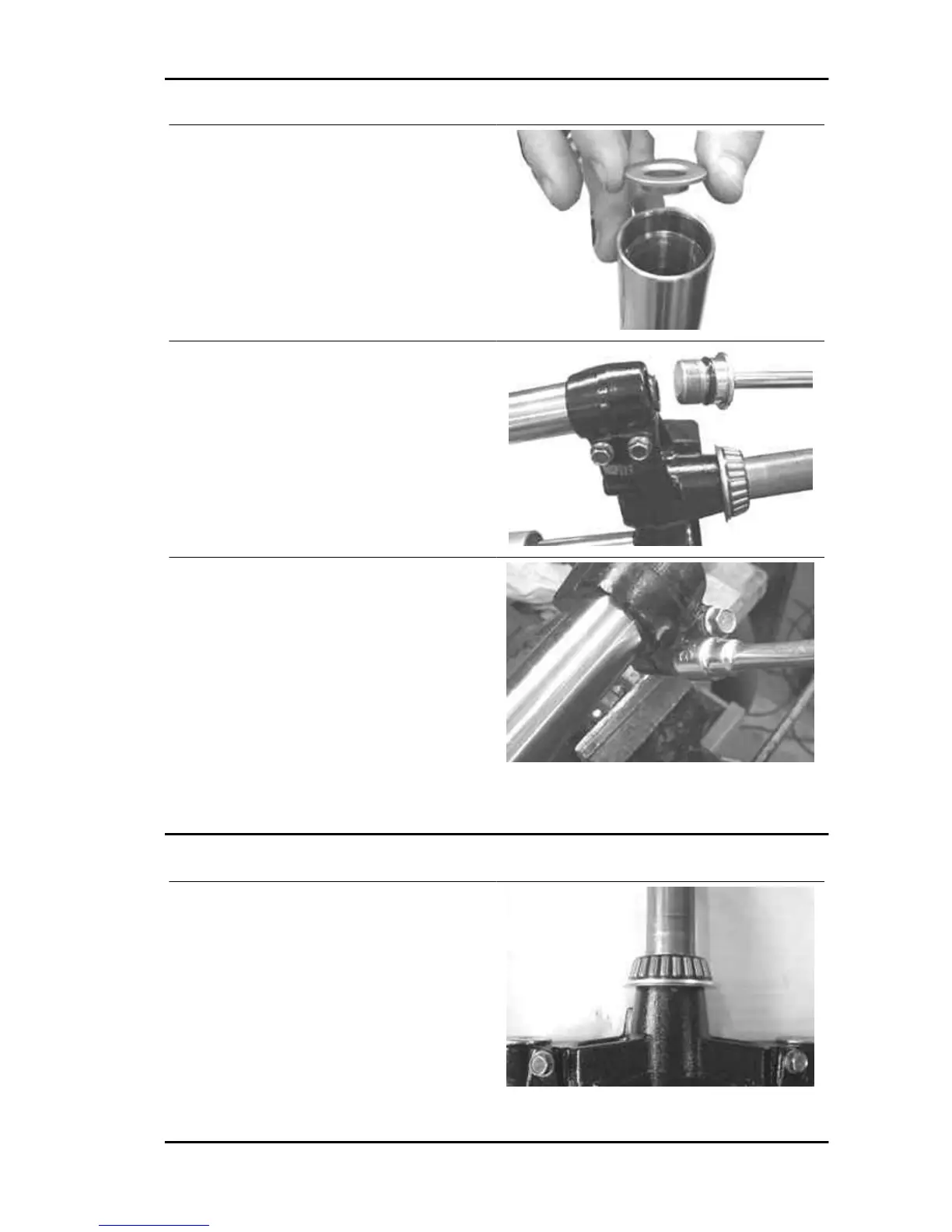

- Insert the 21 winding springs, the support plate

with the chamfer facing downwards and then the

15 winding spring.

- Insert the stem into the fork clamp.

- Do up the clamp once to allow the stem closure

upper cap to be tightened.

- Check that the sealing ring on the cap is in good

working order, then tighten the cap on the stem to

the prescribed torque.

- Loosen the fork clamp screws and ensure the

stem closure cap is fitted properly on the clamp.

- Tighten the clamp screws to the prescribed tor-

que.

Specific tooling

020376Y Adaptor handle

020359Y 42x47-mm adaptor

Locking torques (N*m)

Fork clamp screws 20 ÷ 25 Stem upper cap 15 ÷

30 Lower screw with copper washer 25 - 35

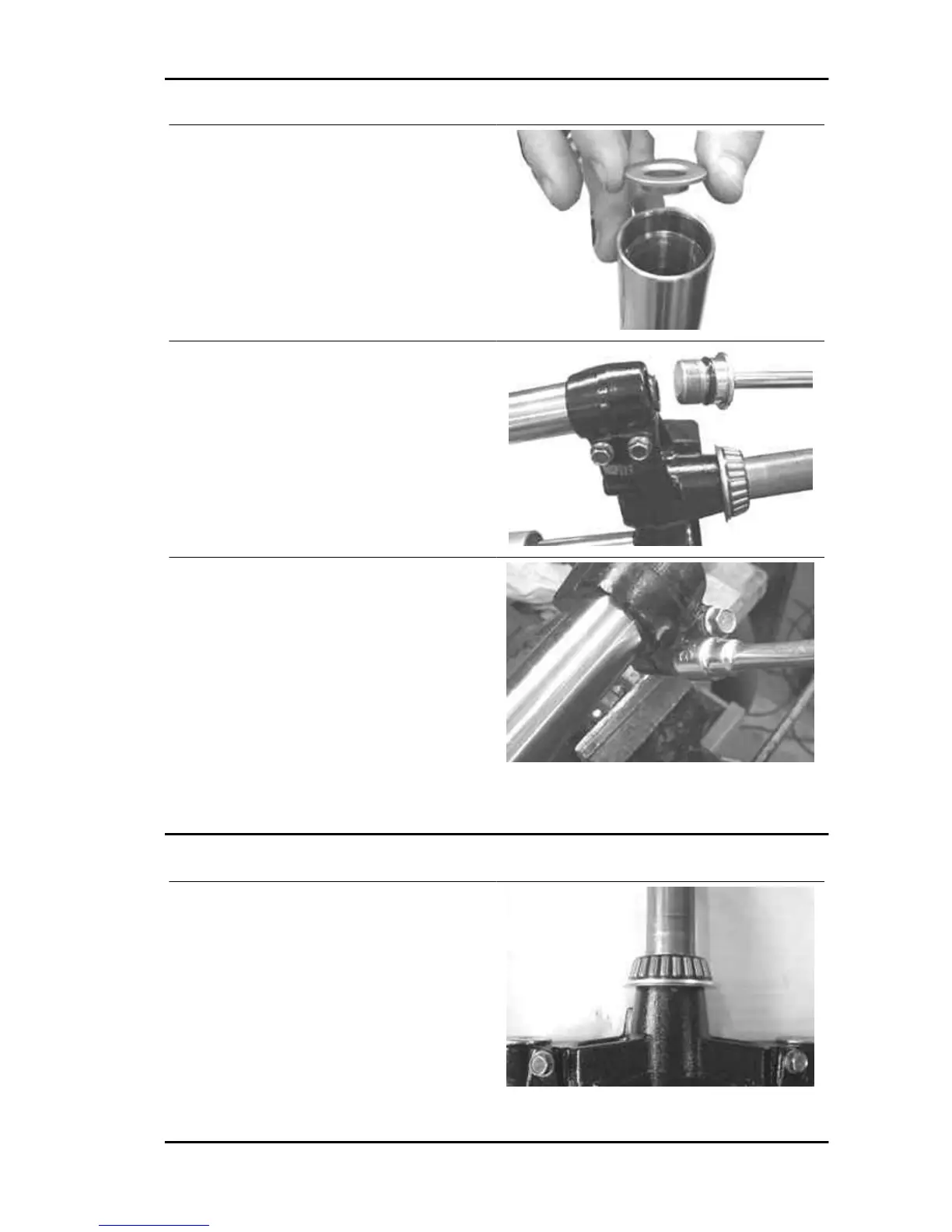

Refitting

- Grease using lithium soap grease on the roller

bearings.

Recommended products

AGIP GREASE PV2 Grease for the steering

bearings, pin seats and swinging arm

White anhydrous-calcium based grease to protect

roller bearings; temperature range between -20 C

and +120 C; NLGI 2; ISO-L-XBCIB2.

Runner 125 - 200 Suspensions

SUSP - 227

Loading...

Loading...