20

SERIES FE

EN

LOW-PRESSURE GAS REGULATOR | SAFETY | REV. 00

Use, maintenance and warning manual

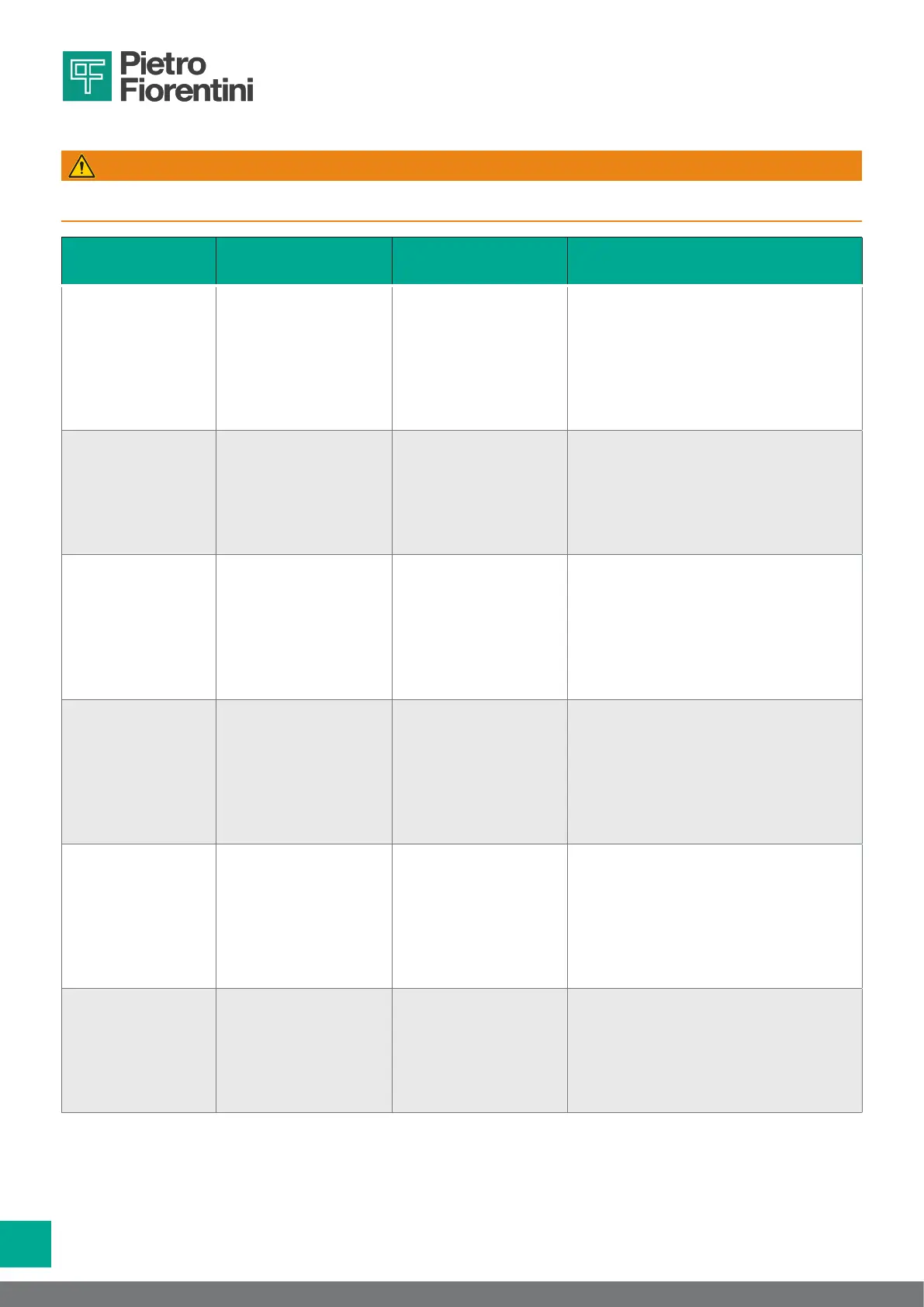

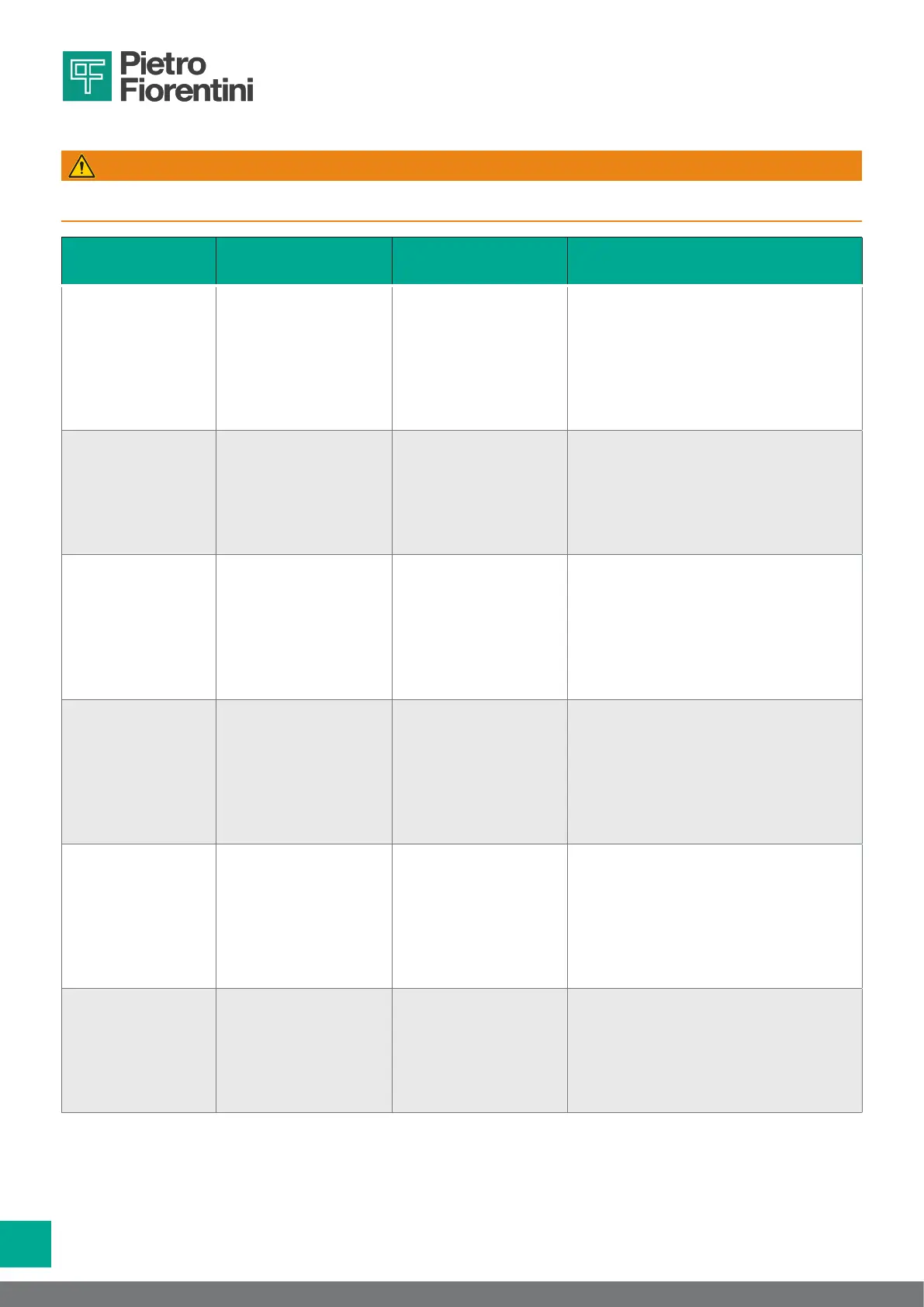

3.3.1 - TABLE SHOWING RESIDUAL RISKS DUE TO PRESSURE

WARNING!

If there are any functional faults, do not operate. Immediately contact PIETRO FIORENTINI S.p.A. for the

necessary directions.

Risk and Hazard Event and Cause

Effect and

Consequence

Solution and Prevention

Pressurised gas

leakage.

Projection of

metallic and

non-metallic

pressurised parts.

• Violent impact.

• Impact (also due

to falling, improper

handling, etc.).

• Deformation.

• Broken connections

and, if under pres-

sure, even burst.

a. Handling and installation with appropri-

ate devices to avoid localised stress.

b. Installation in suitable places and spac-

es with appropriate protections, suitable

packaging.

c. Information/directions contained in this

manual.

Pressurised

gas leakage.

Projection of

metallic and

non-metallic

pressurised parts.

• Use of inappropriate

uids.

• Corrosion.

• Embrittlement.

• Explosion.

a. The user must check compliance of the

used uid with what is indicated on the in-

stallation sheet.

Pressurised gas

leakage.

Projection of

metallic and

non-metallic

pressurised parts.

• Operation at tem-

peratures below the

minimum permissi-

ble temperature.

• Embrittlement.

• Breakage.

• Explosion.

a. Install in places where the temperature

is not below the minimum permissible tem-

perature and/or insulate the equipment

adequately.

b. The minimum allowable temperature is

specied in this manual (refer to paragraph

4.5).

Pressurised gas

leakage.

Projection of

metallic and

non-metallic

pressurised parts.

Explosion.

• Overpressure or

exceeding of the

rated limit values

(maximum pressure

allowed).

• Explosion.

• Breaks.

• Cracks.

• Permanent defor-

mations.

a. The device has appropriate design safe-

ty margins.

b. The user must check the maximum

pressure applicable to the equipment.

c. The design pressure is specied in this

manual (refer to paragraph 4.5).

Pressurised uid

leakage.

Projection of

metallic and

non-metallic

pressurised parts.

• Incorrect xing of

the equipment.

• Deformation.

• Breakage.

a.The device is equipped with unied type

process connections and compression t-

tings.

b. The installer must ensure correct xing

to the line.

c. Information/directions contained in this

manual.

Explosion

of the device

pressurised uid

leakage.

Projection of

metallic parts.

• Operation at tem-

peratures above the

maximum permissi-

ble temperature.

• Reduction of me-

chanical resistance,

breakage of the

device.

• Explosion.

a. The commissioning technician must

equip the system with suitable control and

safety devices.

b. The maximum allowable temperature is

specied in this manual (refer to paragraph

4.5).

Loading...

Loading...