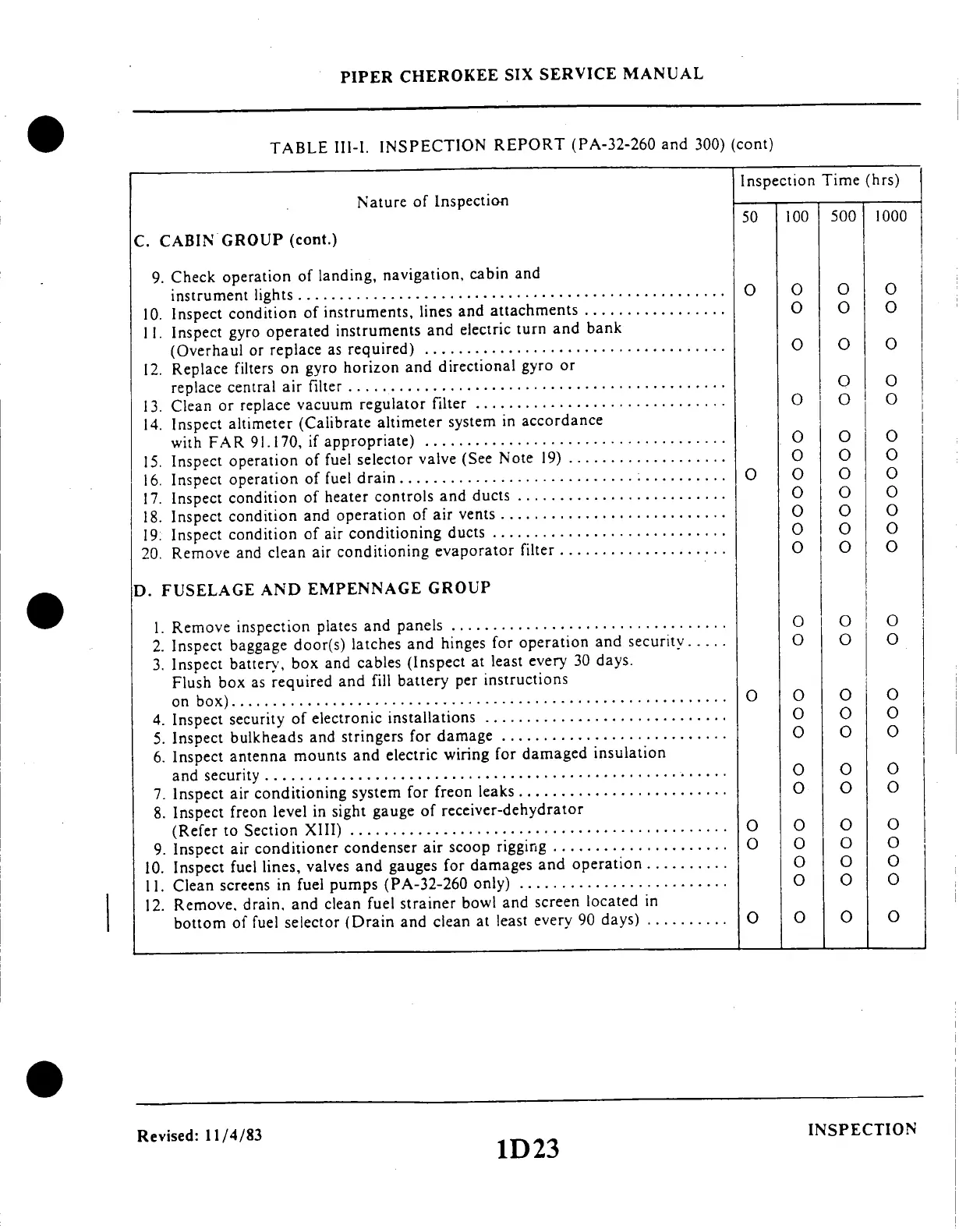

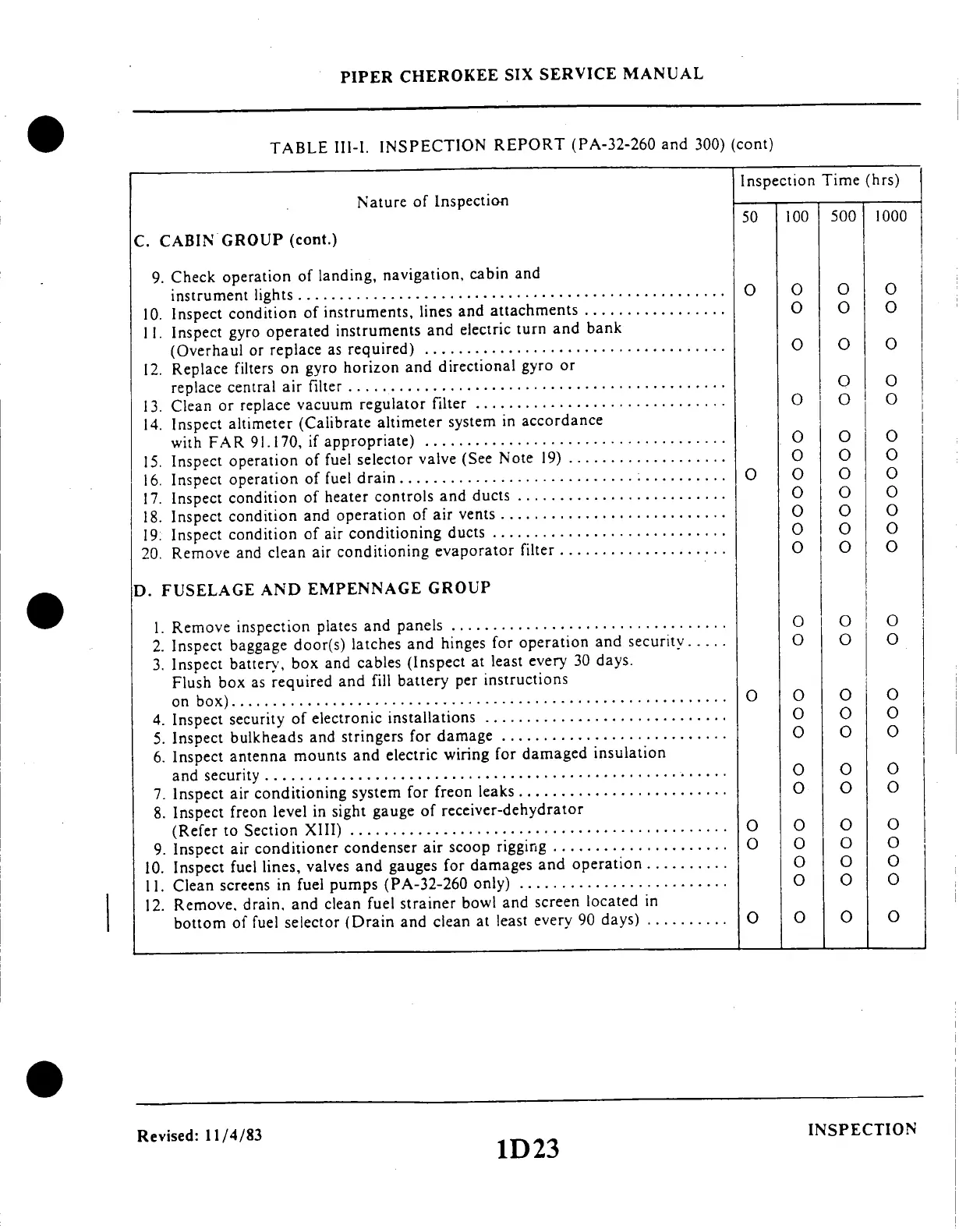

9.

Check

operation

of

landing,

navigation,

cabin

and

instrument

lights

...............

.................................

10.

Inspect

condition

of

instruments,

lines

and

attachments

.................

II.

Inspect

gyro

operated

instruments

and

electric

turn

and

bank

(Overhaul

or

replace

as

required)

....................................

12.

Replace

filters

on

gyro

horizon

and

directional

gyro

or

replace

central

air

filter

.............................................

13.

Clean

or

replace

vacuum

regulator

filter

..............................

14.

Inspect

altimeter

(Calibrate

altimeter

system

in

accordance

with

FAR

91.170,

if

appropriate)

....................................

15.

Inspect

operation

of

fuel

selector

valve

(See

Note

19)

...................

16.

Inspect

operation

of

fuel

drain

.......................................

17.

Inspect

condition

of

heater

controls

and

ducts

.........................

18.

Inspect

condition

and

operation

of

air

vents

...........................

19.

Inspect

condition

of

air

conditioning

ducts

............................

20.

Remove

and

clean

air

conditioning

evaporator

filter

....................

0

Revised:

11/4/83

PIPER

CHEROKEE

SIX

SERVICE

MANUAL

TABLE

Ill-1.

INSPECTION

REPORT

(PA-32-260

and

300)

(cont)

Inspection

Time

(hrs)

Nature

of

Inspection

50

100

500

1000

C.

CABIN

GROUP

(cont.)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0O

0

0

0

0

0 0

0

0

0

0

0 0

0

0

0

0

0

0

D.

FUSELAGE

AND

EMPENNAGE

GROUP

1.

Remove

inspection

plates

and

panels

.................................

2.

Inspect

baggage

door(s)

latches

and

hinges

for

operation

and

security.....

3.

Inspect

battery,

box

and

cables

(Inspect

at

least

every

30

days.

Flush

box

as

required

and

fill

battery

per

instructions

on

box)...........................................................

4.

Inspect

security

of

electronic

installations

.............................

5.

Inspect

bulkheads

and

stringers

for

damage

...........................

6.

Inspect

antenna

mounts

and

electric

wiring

for

damaged

insulation

and

security

.......................................................

7.

Inspect

air

conditioning

system

for

freon

leaks

.........................

8.

Inspect

freon

level

in

sight

gauge

of

receiver-dehydrator

(Refer

to

Section

XIII)

.............................................

9.

Inspect

air

conditioner

condenser

air

scoop

rigging

.....................

10.

Inspect

fuel

lines,

valves

and

gauges

for

damages

and

operation

..........

11.

Clean

screens

in

fuel

pumps

(PA-32-260

only)

.........................

12.

Remove,

drain,

and

clean

fuel

strainer

bowl

and

screen

located

in

bottom

of

fuel

selector

(Drain

and

clean

at

least

every

90

days)

..........

0

0

0

0

i

0

0

0

0

0

0

O

U

U

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 0 0

INSPECTION

1D23

Loading...

Loading...