46

FAULT FINDING

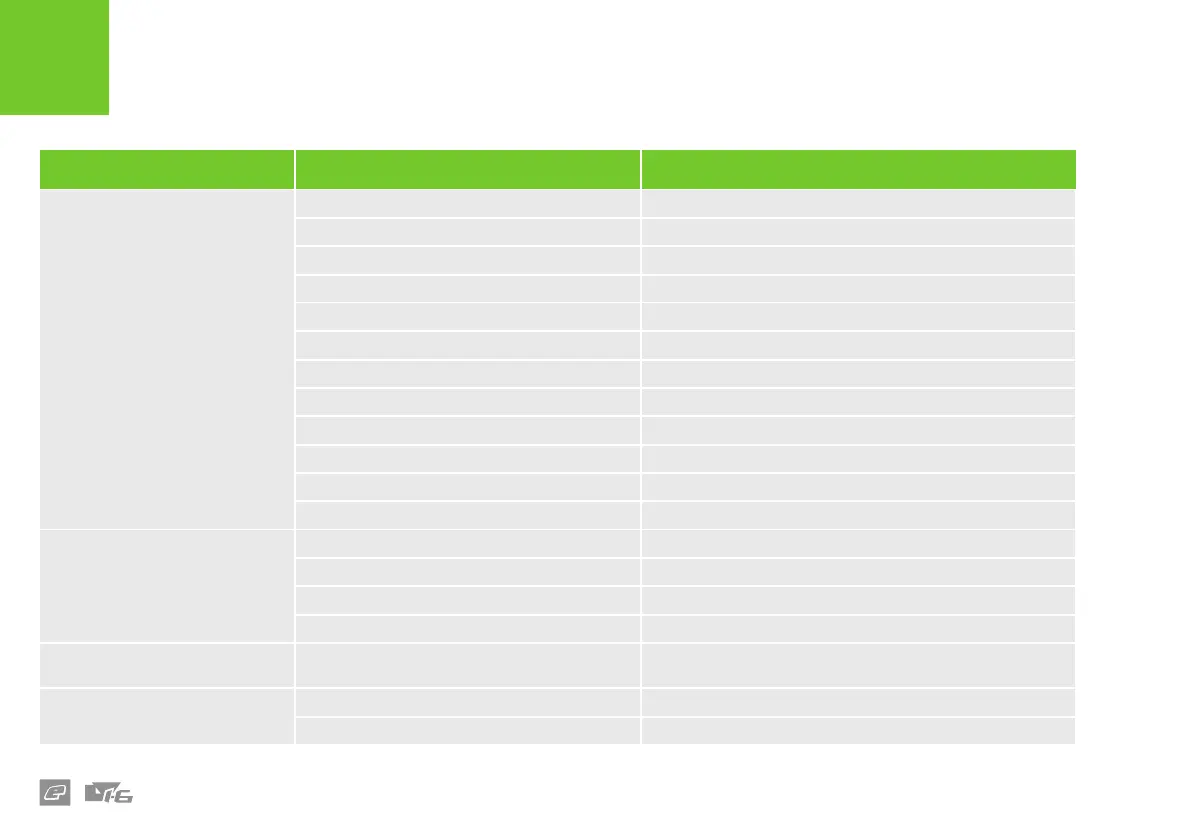

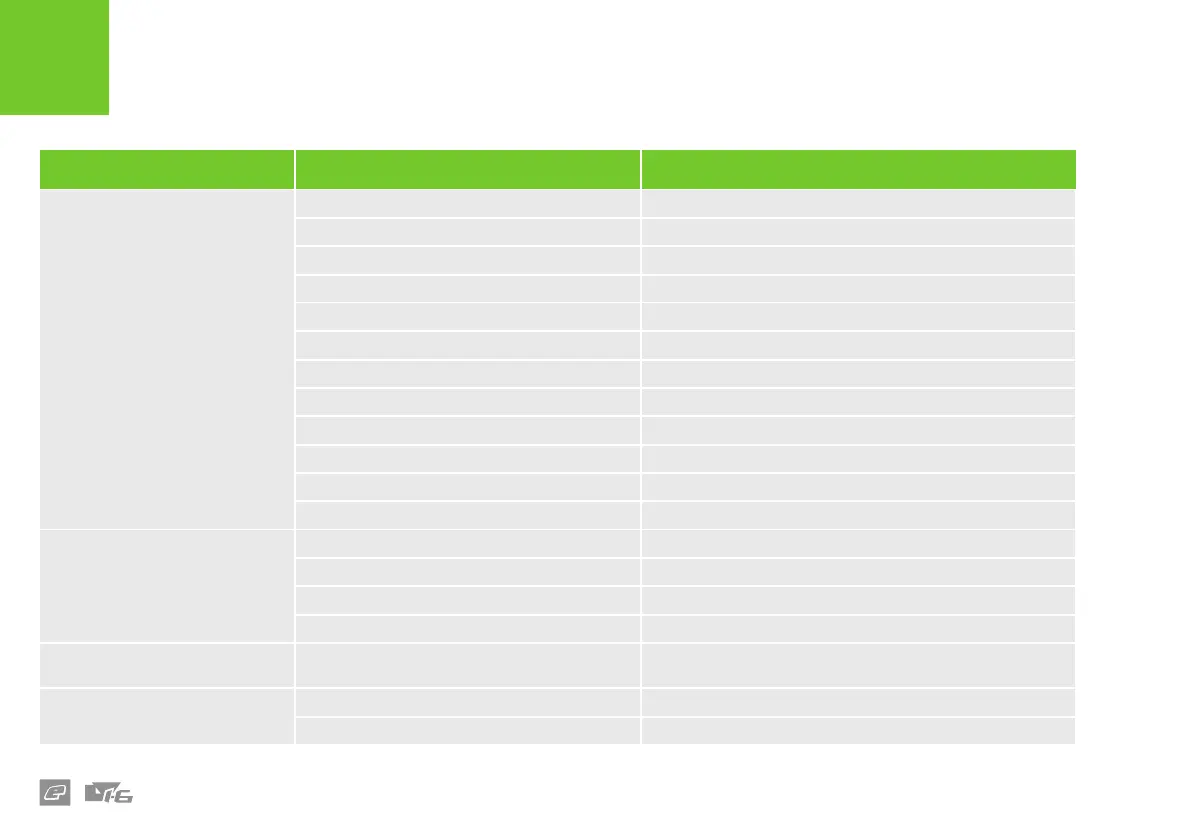

FAULT FINDING TABLES

SYMPTOM POSSIBLE CAUSE SOLUTION

The marker does not re.

The POPS is not fully engaged. Push the POPS bonnet back until it engages.

The solenoid ow restrictors (SFRs) are set too low. Set the SFRs to their factory settings.

The battery quality or charge level is very low. Install a new high quality Alkaline battery.

The battery is at. Replace te battery.

The Training mode is enabled. Disable Training mode.

The Dwell parameter is set too low. Increase the Dwell parameter.

The trigger is set up incorrectly. Set up the trigger correctly so that it pulls freely.

The solenoid is not plugged into the PCB. Plug solenoid wire into the port on the PCB.

The BS is enabled but there is no paint in the breech. Fill loader with paint.

The OPTO sensor/micro-switch is not being activated. Adjust the trigger accordingly.

The PCB is damaged. Replace the PCB.

The solenoid valve is damaged. Replace solenoid valve.

Velocity drop-off during rapid re.

The battery quality or charge level is low. Install a new high quality Alkaline battery.

The solenoid ow restrictor (SFR) is set too low. Increase the SFR settings to factory default.

The air system regulator ow is too low. Try another air system.

Dirty/partially blocked regulator. Strip, clean, lubricate and rebuild the regulator.

The Breech Sensor (BS) does not

appear to be reading correctly.

The BS is dirty. Access and clean the Breech Sensors.

Two or more balls are being fed into the

breech.

Worn/damaged detents. Replace the rubber detents.

The feed force is too high from the loader. Adjust the loader settings accordingly.

Loading...

Loading...