6-12

6 Technical Specifications

6.7.2 Topography Measurements

INFORMATION

The values given apply to a measurement with a 10x objective with a

scanning rate of 3.36 µm/s. This corresponds to a sampling interval of 80 nm.

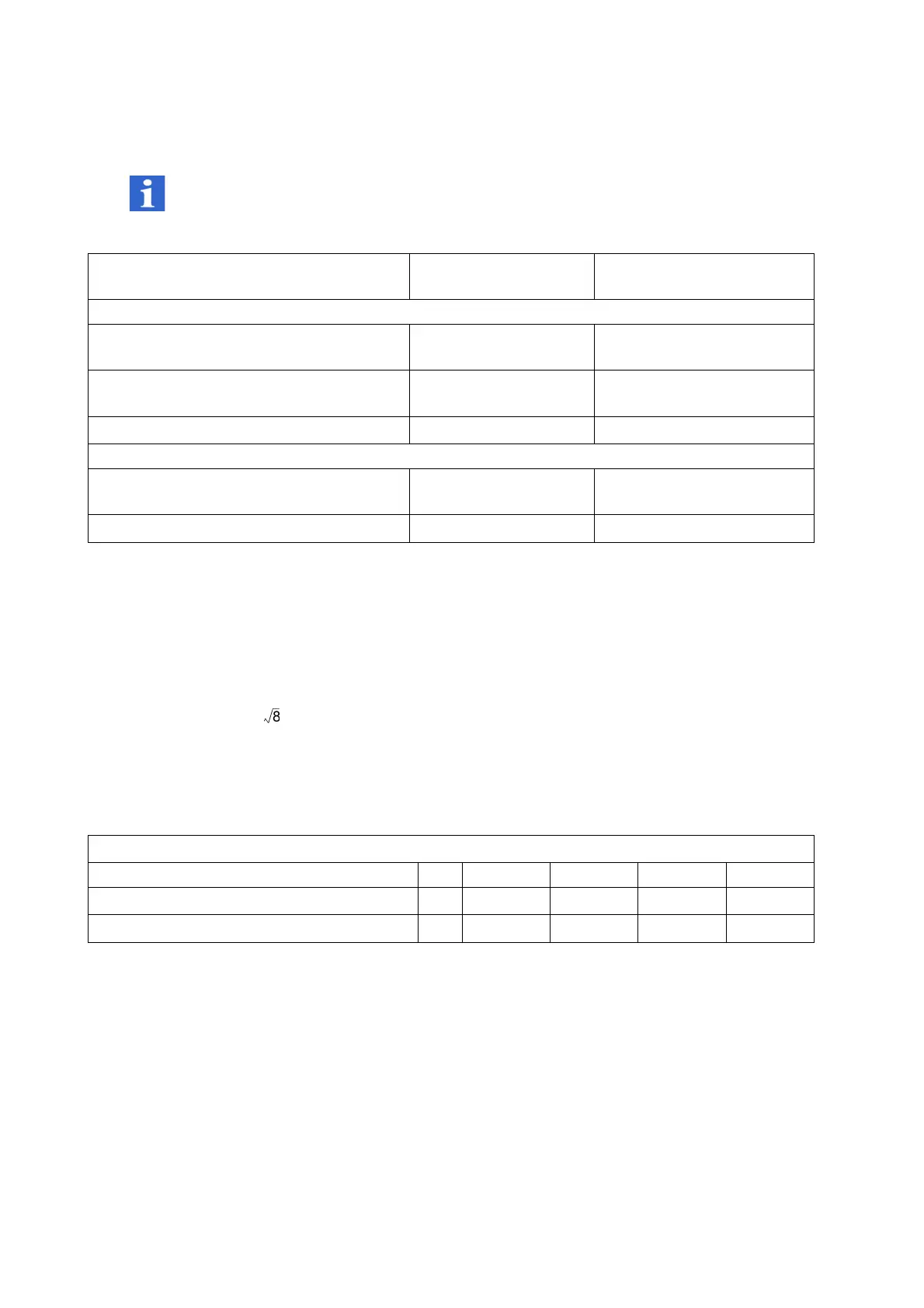

Surface

Smooth

1

(Phase

evaluation)

Rough

2

(Envelope

evaluation)

Z performance:

Measurement noise (N = 25) (measurement

noise of an averaged measurement)

3

0.09 nm 6 nm

Average measurement noise (stabilized

measurement noise)

4

0.35 nm 16 nm

Vertical resolution

5

<1nm <37nm

Flatness measurement:

Average flatness deviation

(stabilized flatness deviation)

6

4.5nm 45nm

Repeatability (N = 50)

7

0.25 nm 14 nm

1

Analysis of the correlogram phase, can be used on flat surfaces.

2

analysis of the correlogram envelope, for usage on unsteady/rough surfaces.

3

RMS value of the signal amplitude for an averaged measurement on a parallelly aligned plane mirror (R ≈ 4%, λ/20),

calculated from 25 single measurements, under repeatability conditions. The averaged data was post-processed as follows:

Alignment, 5 x 5 median filter with threshold 3 nm (phase evaluation)/40 nm (envelope evaluation), high pass filter

λc = 0.25 mm. The reference file has also been created from an averaging of 25 measurements.

4

Averaged RMS value of the signal amplitude of 49 differential topographies calculated from 50 subsequent measurements on

a parallelly aligned plane mirror (R ≈ 4%, λ/20) under repeatability conditions. The data was post-processed as follows:

Alignment, 5 x 5 median filter with threshold 3 nm (phase evaluation)/40 nm (envelope evaluation), high pass filter

λc=0.25mm.

5

Measurement noise (N = 1) ·

6

Mean value of measured flatness values (according to ISO 1101) of 50 measurements on a parallelly aligned plane mirror

(R ≈ 4%, λ/20) under repeatability conditions. The measurements were post-processed as follows: Alignment, 5 x 5 median

filter with threshold 3 nm (phase evaluation)/30 nm (envelope evaluation), low pass filter λc = 0.02 mm.

7

Standard deviation of the measured flatness values (according to ISO 1101) of 50 measurements on a parallelly aligned plane

mirror (R ≈ 4%, λ/20) under repeatability conditions. The measurements were post-processed as follows: Alignment, 5 x 5

median filter with threshold 3 nm (phase evaluation)/30 nm (envelope evaluation), low pass filter λc = 0.02 mm.

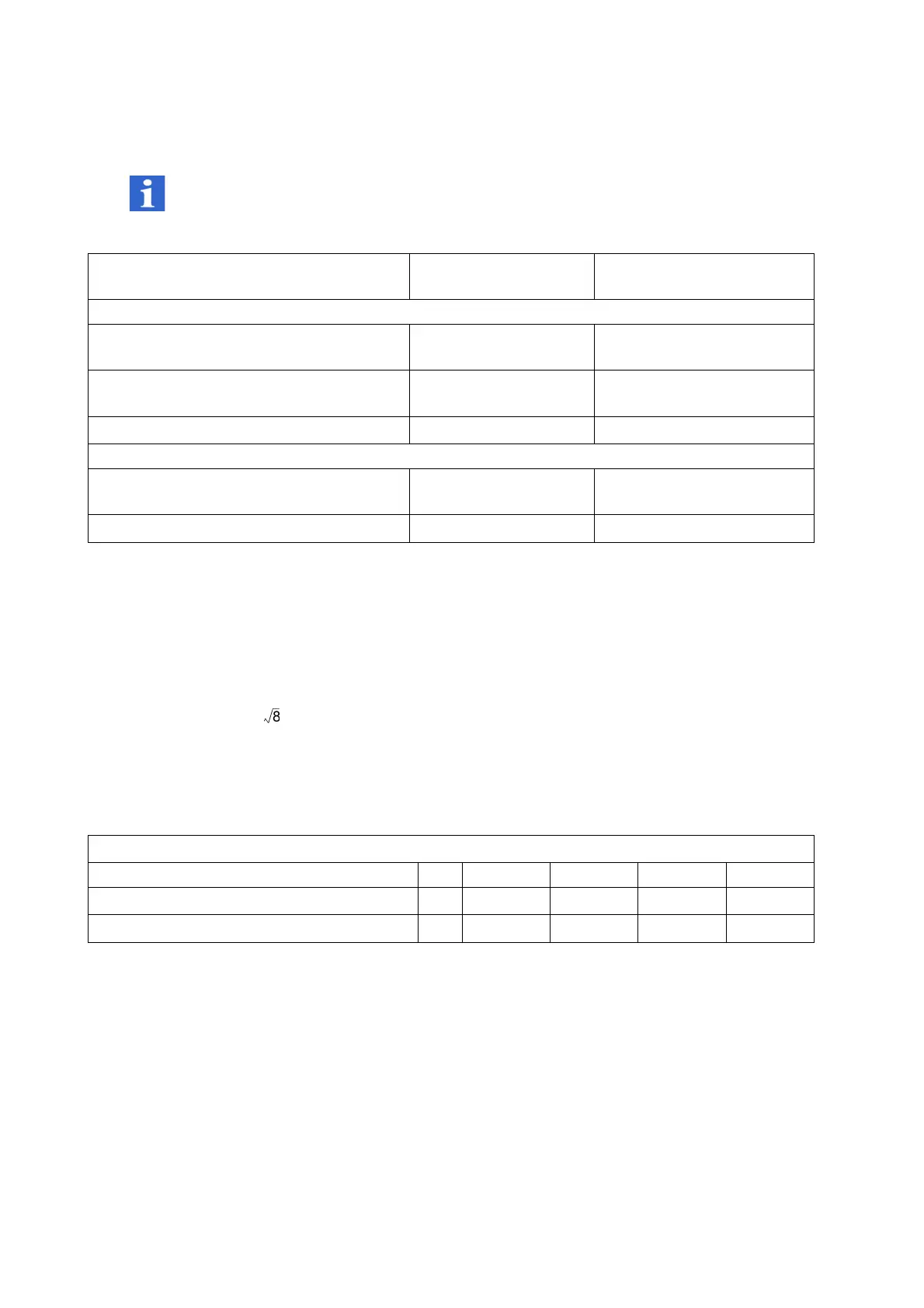

Step Height Measurement on a calibrated Depth Setting Standard

1

2

Nominal step height

[µm] 0.24 0.75 7.5 75

Repeatability (Standard Deviation)

3

[µm] 0.02 0.04 0.05 0.06

Maximum Deviation

4

[µm] 0.05 0.12 0.16 0.18

1

Analysis of the correlogram envelope, for usage on unsteady/rough surfaces.

2

15 measurements per step on a calibrated depth setting standard, type KNT 4080/30 (ISO 5436-1)

3

Standard deviation of the measured deviation of the calibrated step height under repeatability conditions.

4

Largest measured deviation in relation to the calibrated step height out of 15 measurements per step under reproducibility

conditions (measured at different sections of the total measurement range, for example).

Loading...

Loading...