To perform a correct terminals connection, follow the next steps.

▪ Refer to section “Power Terminals” for recommended screws and washers

metrics, as well as recommended torque.

▪ The number of busbars depends on the frame size. Check the “Power

terminals” section.

▪ Before connecting the cables, clean the contact surface with a clean cloth and

ethanol cleaner.

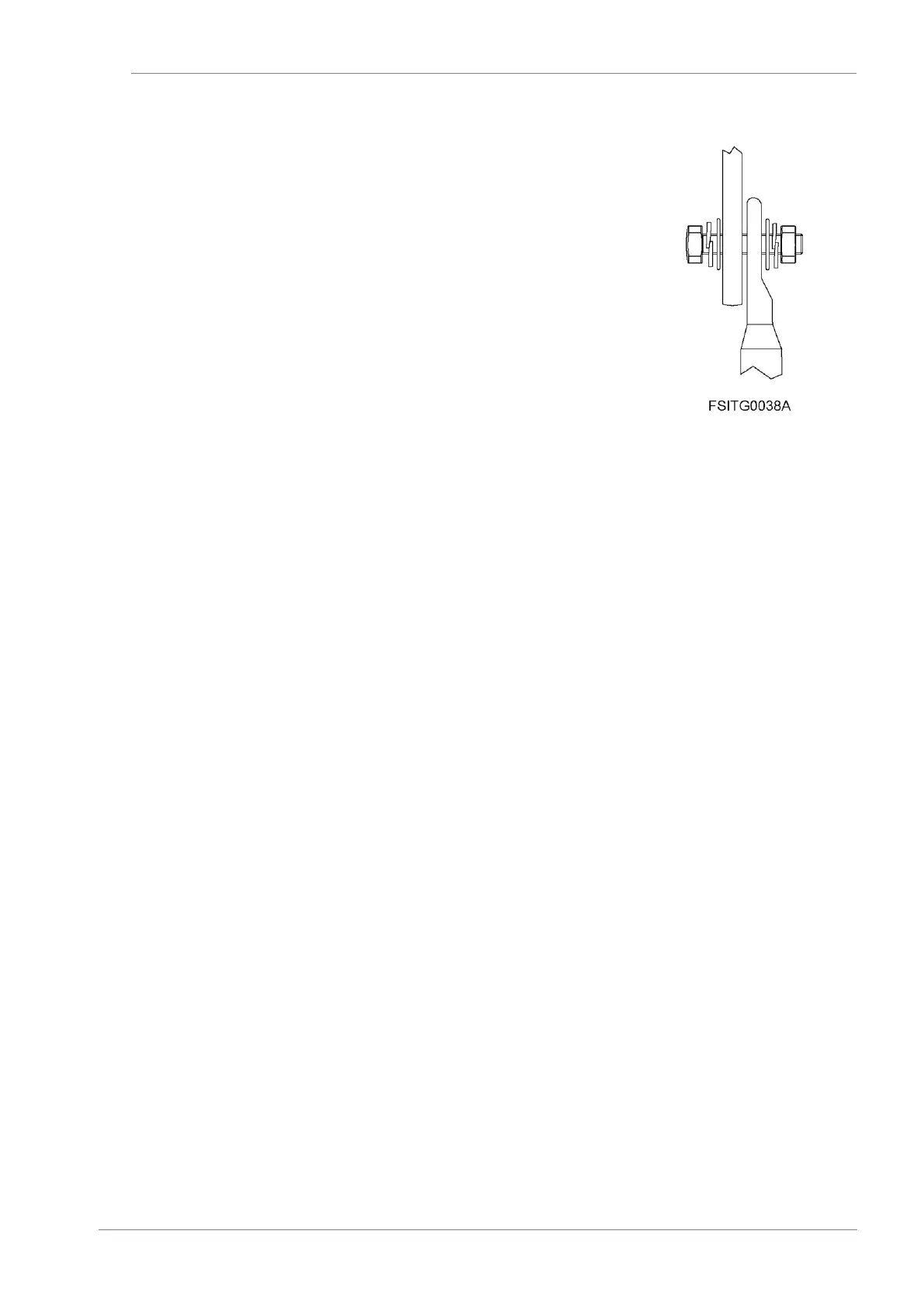

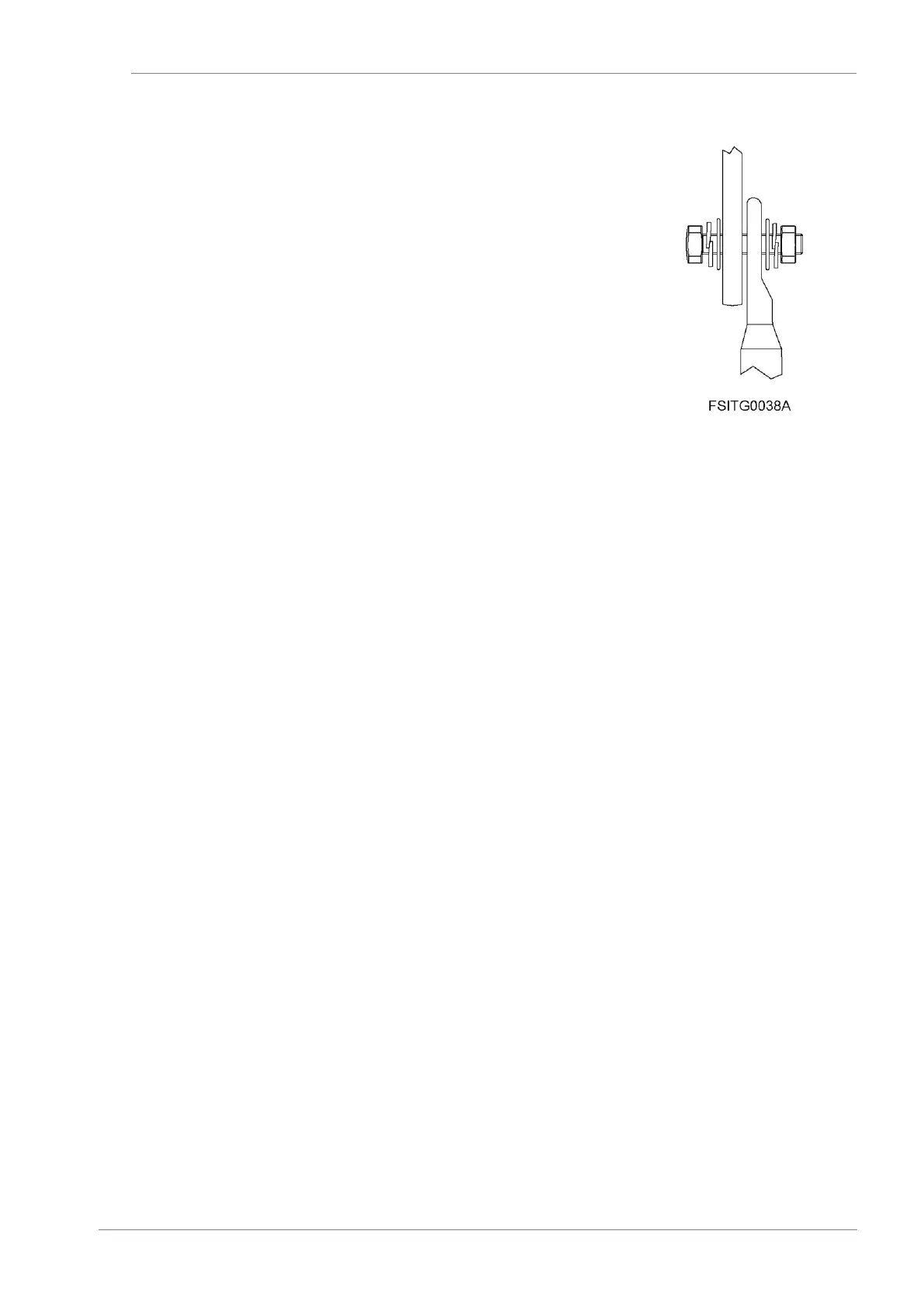

▪ Use a pressure washer and a flat washer between the nut or bolt head and

the terminal lug.

▪ Use copper or aluminium conductors that whithstand a voltage of 600Vac for

equipment with rated voltage up to 500Vac..

The recommended cable types and lengths between the drive (with factory settings) and the motor are:

▪ Unshielded cable: 300m. Asymmetrical 4-wire cable including PE conductor. It is recommended

to use a motor ground cable (PE) with a cross section equal or higher than the supply motor wires

cross section (U, V, W). When single-wire cables are used in three-phase systems, the three

phase conductors must be bundled symmetrically.

▪ Shielded cable: 150m. Symmetrical 3-wire cable with PE conductor- with concentric shield. To

implement an effective shield bonding, an EMC cable gland should be used in both the motor

junction box and the drive cabinet to ensure effective 360º ground connection and a low

impedance path for high frequency current. Refer to “EMC Installation Requeriments” section.

Loading...

Loading...