Line voltage (input supply) must never be connected to U, V and W terminals.

Otherwise, the drive will be damaged.

It is absolutely necessary that the installer ensures correct compliance with the laws and

regulations in force in the countries or areas where the drive is to be installed.

Do not use capacitors for power factor correction, surge suppressors or RFI filters on the output

side of the drive. Doing so may damage these components or the drive itself.

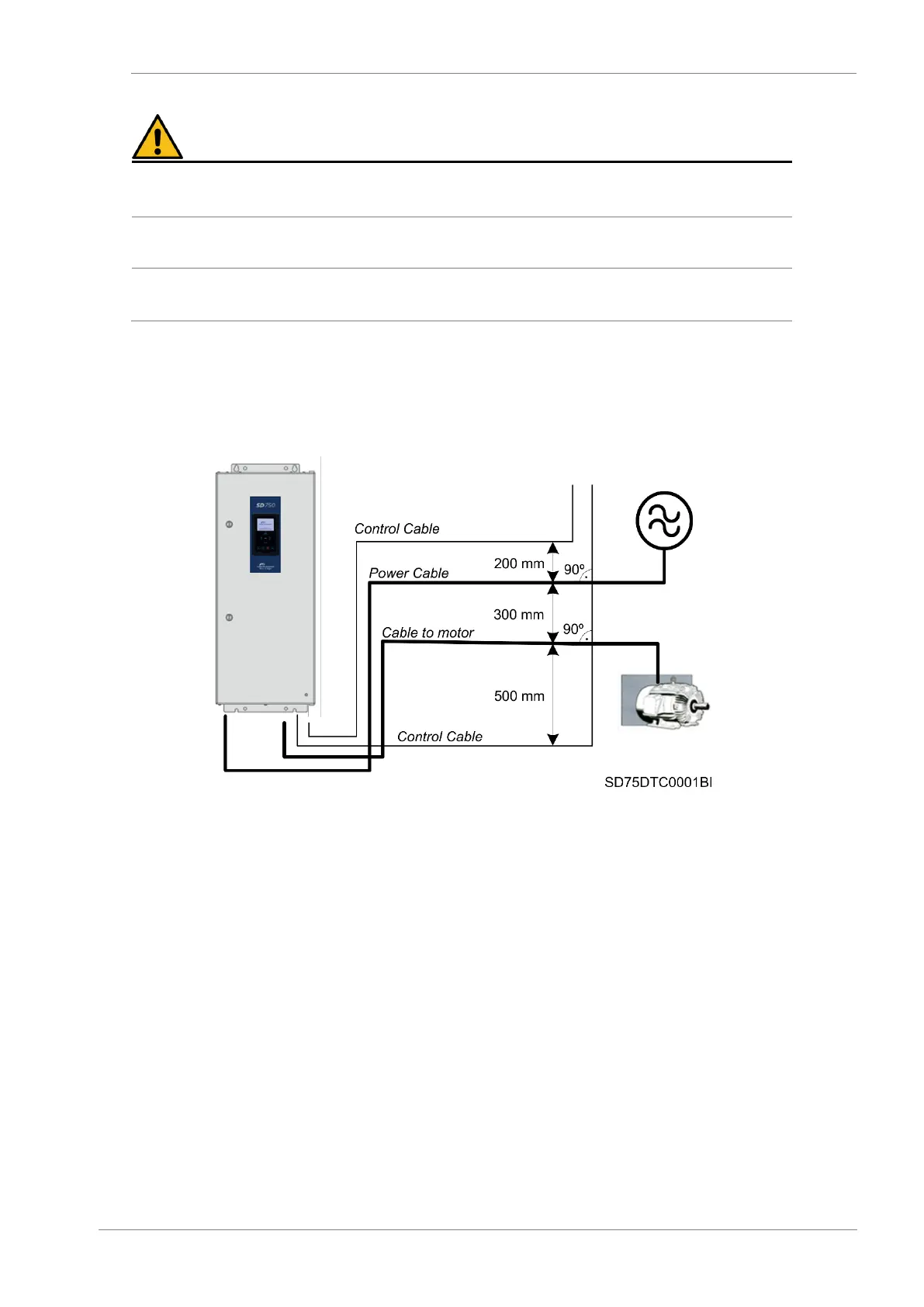

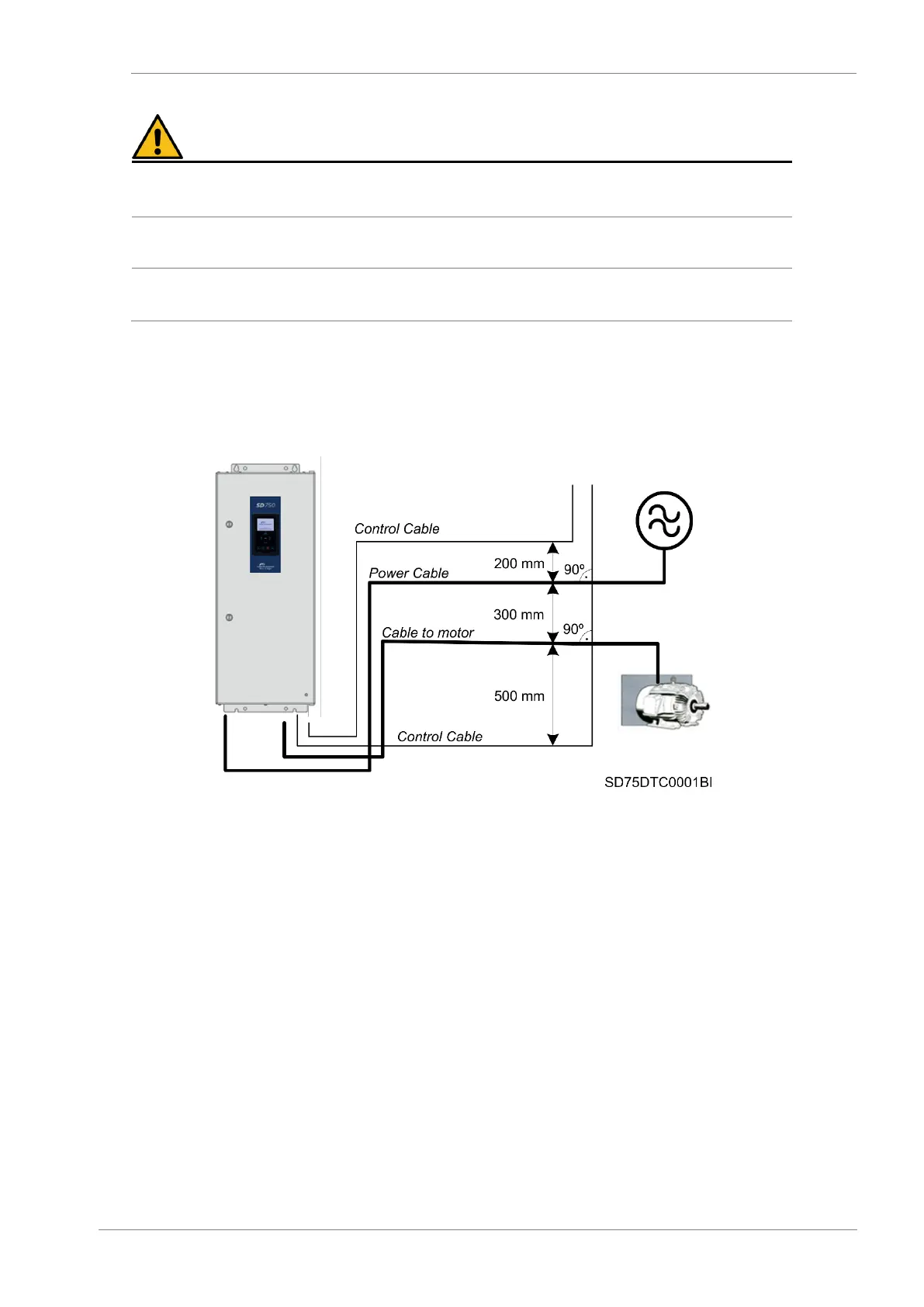

All power conductors such as power input cables, output cables to the motor or DC link cables must be

separated from the control, signal, PTC, encoder or data cables. The recommended distances between

the cables are shown in the next figure:

Cable routing distances

Power Electronics recommends that the following cable types are installed in cable racks, trays or in

different wire ducts:

▪ Single-wire signal or data cables with V< 60V

▪ Single-wire cables with 60V<V< 230V

▪ Input power cables with a low level of interferences 230V<V<1000V

▪ Output power cables to the motor and dynamic DC brake with a high level of interference

230V<V<1000V.

▪ Medium voltage cables with V<1000V

Power cables must have a sufficient nominal current to prevent important wiring overheating and voltage

drops. The installer must consider the cable cross-section, cable type, wiring method and ambient

conditions to select the appropriate cable. It is only permitted the use of cooper or aluminium cables.

Please check the maximum cable section and the available holes per phase in section “Power terminals”.

Loading...

Loading...