Loop Leader PD6600 Series Loop-Powered Meters Instruction Manual

19

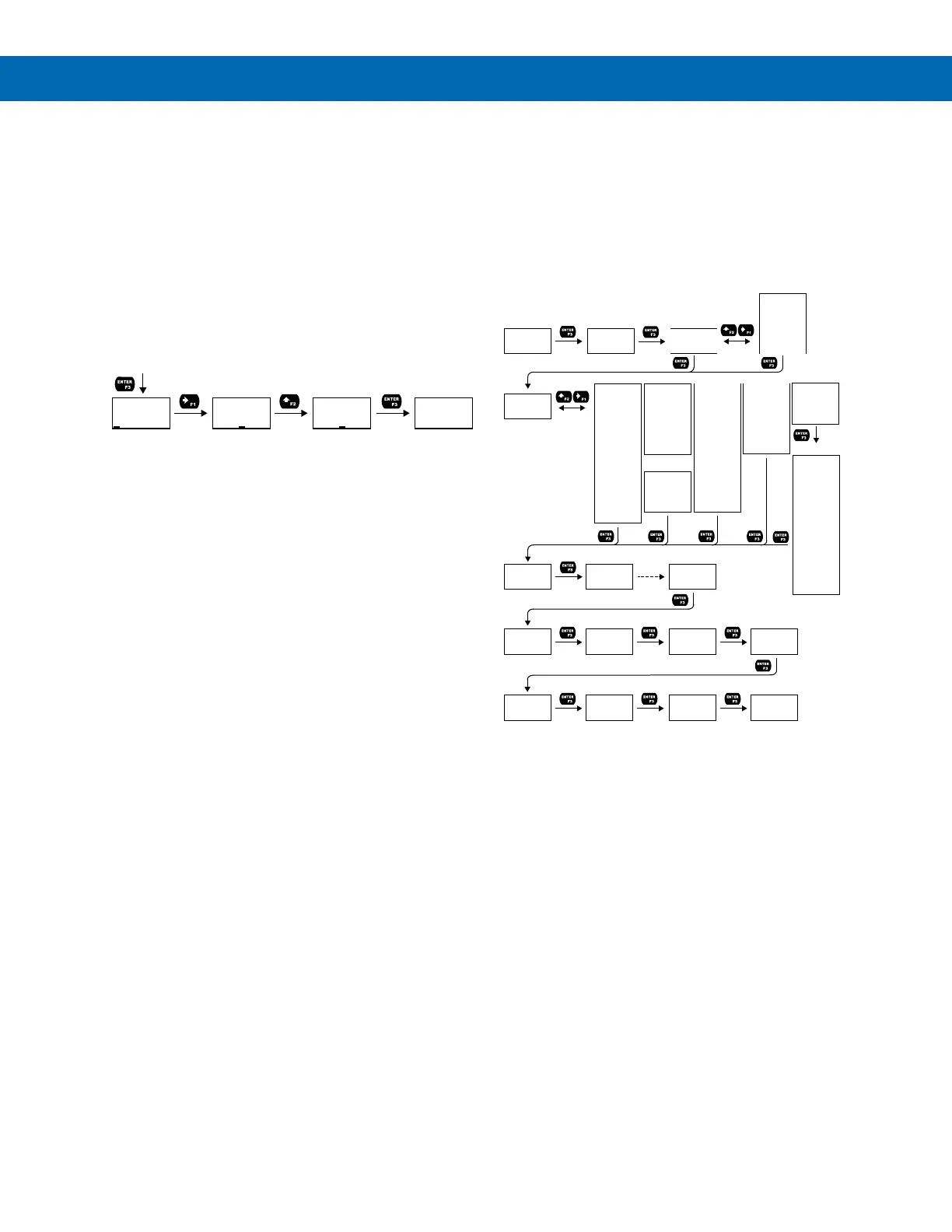

Setting Numeric Values

The numeric values are set using the Right and Up-

Arrow buttons. Press Right-Arrow to select next digit

and Up-Arrow to increment digit value. The selected

digit will flash.

Press and hold Up-Arrow to auto-increment the

display value. If you have made a mistake or would

like to enter a new value, select the left-most digit and

press and hold the Right-Arrow button until all digits

reset to zero.

Press the Enter button at any time to accept a setting

or Menu button to exit without saving changes.

Note: the underscore in the graphic below is provided

to show which digit would be flashing.

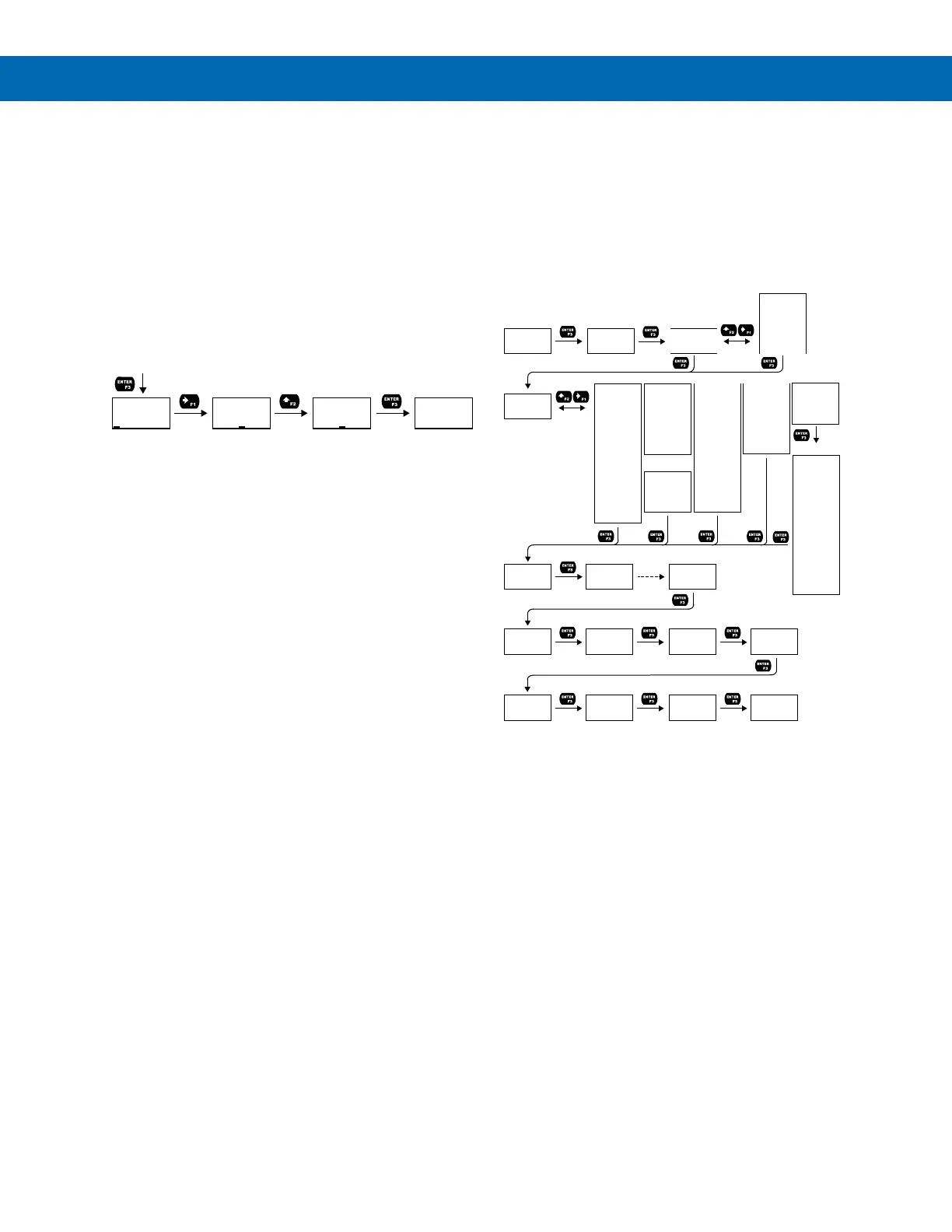

Scaling the 4-20 mA Input (SCALE)

The 4-20 mA input can be scaled to the appropriate

values for a given application. The 4 mA input

(input 1) should have a corresponding display value

(display 1) which represents the low end of the pro-

cess value range being measured by the transmitter.

Likewise, the 20 mA input (input 2) should have a

display value (display 2) which represents the high

end of the process value range.

For example: If the meter is used to display the level

of a 100 foot tall tank, the transmitter will send a 4 mA

signal when the tank is empty and a 20 mA signal

when the tank is full. The meter should be scaled

such that 4 mA corresponds to a display of 0 and 20

mA to a display of 100. If the application required the

meter to display how much room was left in the tank,

the meter could be reversed scaled such that a 4 mA

input displays 100 and a 20 mA input displays 0.

Processes which require a non-linear scale can be

accommodated using the linear (LINEAR), exponent

(EXPONENT), square root (SQROOT), and round hori-

zontal tank (RH TANK) functions available in the

Advanced menu. See Signal Input Conditioning

Functions (FUNCTION) on page 30.

A signal source is not needed to scale the meter;

simply program the inputs and corresponding display

values.

DSP 1

+00,000.00

DSP 1

00,000.00

Select

Digit to

Change

DSP 1

00,050.00

Increment

Selected

Digit

SCALE

INPUT 2

Accept

Setting

SETUP

INPUT

SCALE

UNITS

SCALE

INPUT 1

SCALE

DISP 1

UNITS

VOLUME

HEIGHT

TEMP

PRESSURE

WEIGHT

RATE

CUSTOM

UNIT

GAL

GAL

L

IGAL

M3

BBL

BUSH

cuYD

cuFt

cuIn

LiBBL

BBBL

HECtL

AF

CUSTOM

INCH

FEET

FT-IN

YARD

CM

M

CUSTOM

~F

~C

K

~RA

PSI

InHg

InH2O

mmHg

kg/CM2

kg/M2

mBAr

Bar

PA

hPA

kPA

MPA

CUSTOM

gm

kg

tonne

oz

1b

ton

CUSTOM

/SECOND

/MINUTE

/HOUR

/DAY

GAL/(T)

L/(T)

IGAL/(T)

M3/(T)

BBL/(T)

BUSH/(T)

cuYD/(T)

cuFt/(T)

cuIn/(T)

LiBBL/

(T)

BBBL/(T)

HECtL/

(T)

AF/(T)

CUSTOM/

Volume Units

Height Units Pressure Units Weight Units

Rate Time

Bases

Rate Units

Temperature

Units

INP 1

04.000

INP 1

mA

Flashes Units

Momentarily

DSP 1

+00,000.00

SCALE

INPUT 2

INP 2

20.000

SCALE

DISP 2

DSP 2

+00,100.00

SAVE?

SETUP

INPUT

Loading...

Loading...