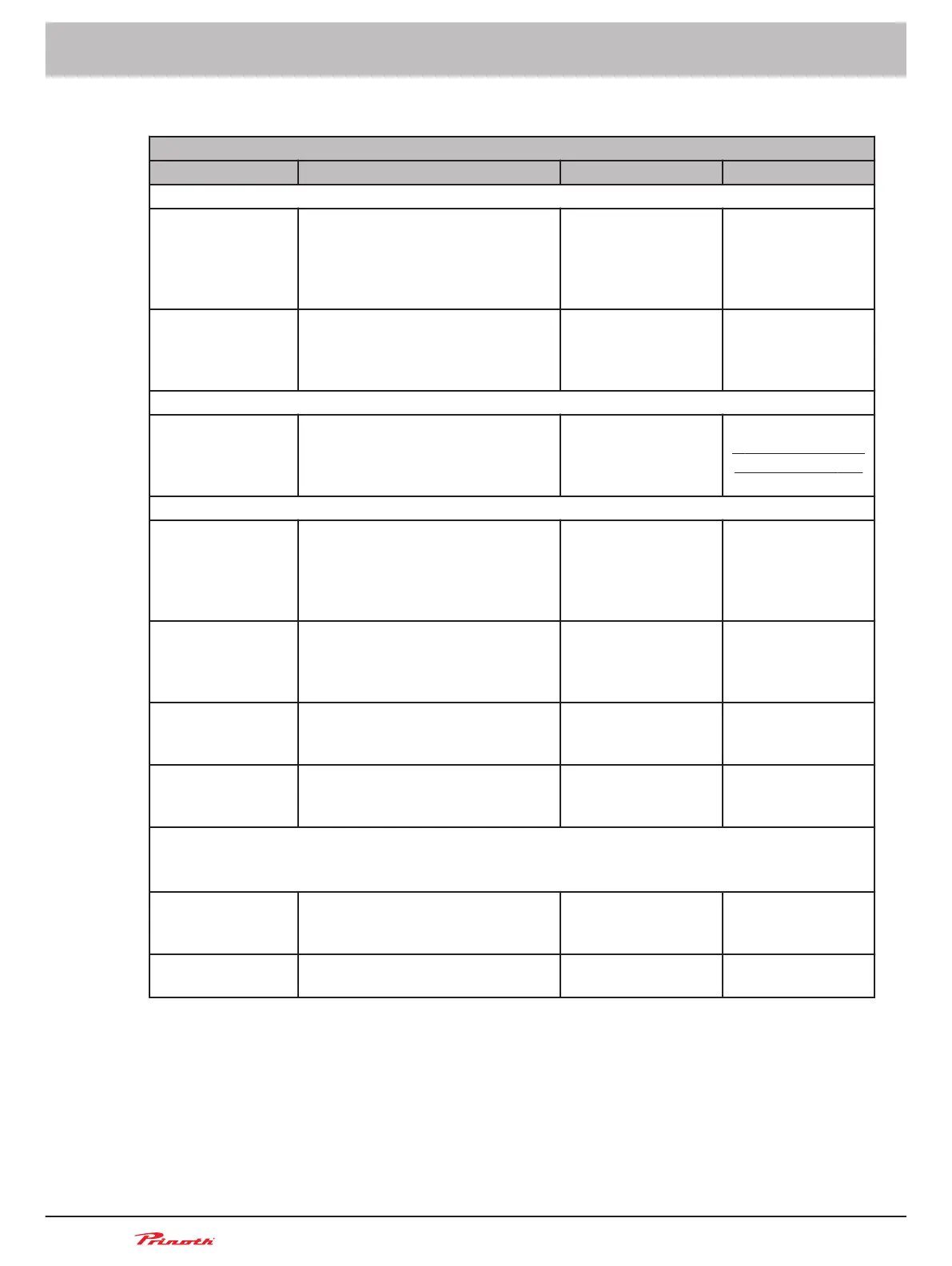

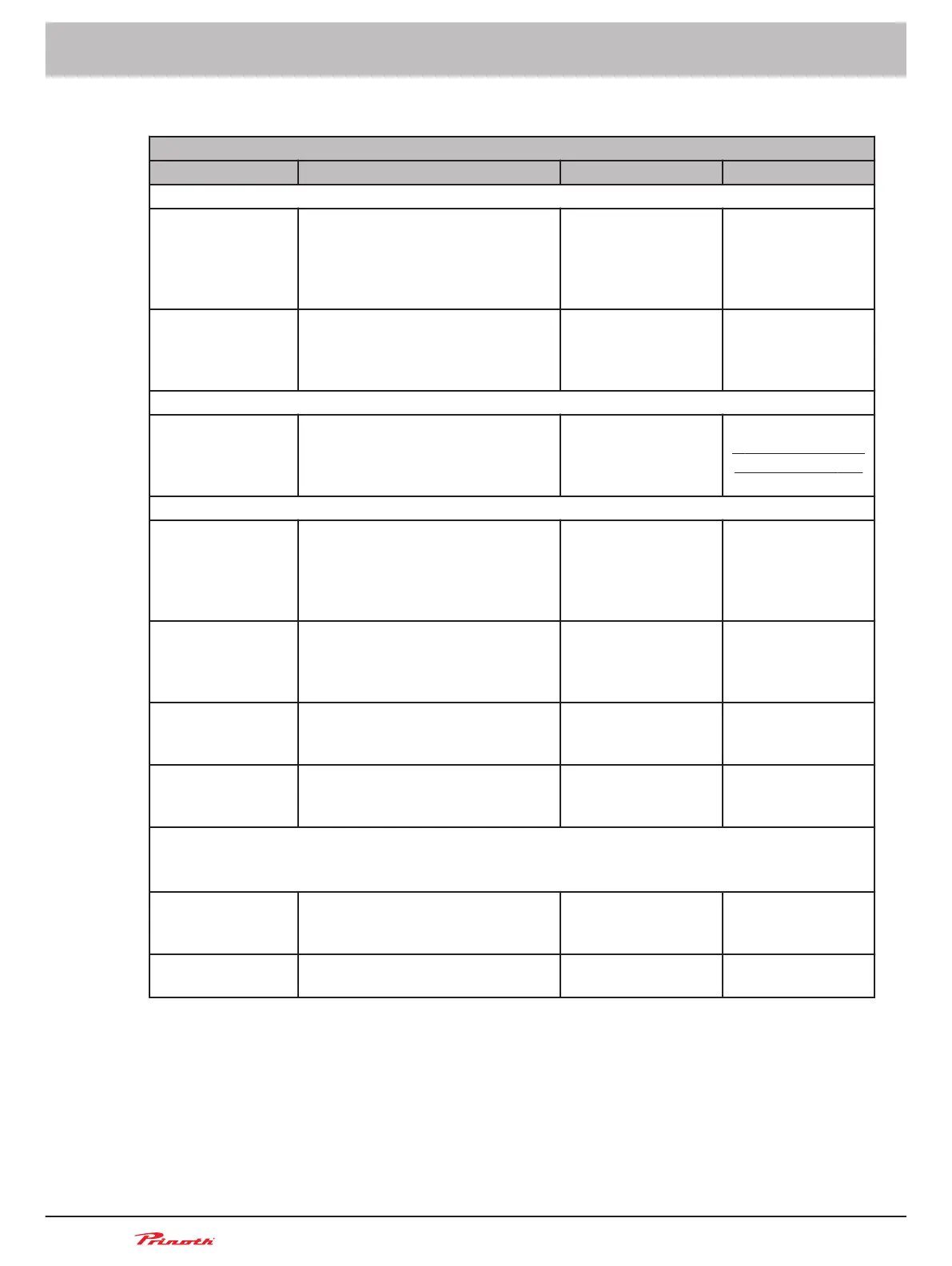

Operating fluids

Operating fluids for AUTOMATIC winch

Specifications Note Qty

HYDRAULIC FLUID

ATF oil

Dexron III, Dexron II, Type F, Type

A Suffix A

Check initial filling!

Oil type must be

identical to the snow

groomer oil type (ini-

tial filling: Dexron III)

10 L (2.6 gal)

Biodegradable oil

Panolin HLP Synth 46, York Bio

777 VG 46

Check initial filling!

The oil type must be

the same as that of

the snow groomer

10 L (2.6 gal)

GEAR OIL

Winch gear

Synthetic gear oil based on PAO

(poly-alpha-olefin) Viscosity: ISO

220, SAE 75W 90 or 75W 140, API

GL-4 or GL-5

(initial filling:

75W140)

➽

See "Check oil level

of winch gear" (p. 242)

LUBRICANT

Bearings and other

lubrication points

Calcium or lithium soap grease,

DIN 51825 KP 2G-30, DIN 51502;

for temperatures below

-30 °C (-22 °F): NLGI grade 1 (no

EP, -40 °C to 100 °C)

ROLL OUT bear-

ing

Lithium soap grease with mineral

base oil and EP additives, type

SKF LGEP2, temperature range

-20 °C (-4 °F) to 110 °C (230 °F)

Cable lubrication

We recommend CIFAST-BRILUBE

30/40/50/60 or equivalent lubricat-

ing grease

Only required for

non-galvanised cable

Cable lubrication at

the end of the sea-

son

We recommend using SHELL 2722

or equivalent lubricating greases

Only required for

non-galvanised cable

HYDRAULIC PUMP

TILT SYSTEM WINCH ARM

HYDRAULIC FLUID

ATF oil

Dexron III, Dexron II, Type F, Type

A Suffix A

Check initial filling!

(initial filling: Dexron

III)

0.2 L (0.05 gal)

Biodegradable oil

Panolin HLP Synth 46, York Bio

777 VG 46

Check initial filling!

0.2 L (0.05 gal)

Lubrication points

The

required lubrication intervals are indicated on the maintenance schedule. Lubricate the points indi-

cated on the following drawing.

■ Before lubricating, thoroughly clean the lubricating nipples in order to prevent dirt or foreign mat-

ter from entering.

■ Damaged lubricating nipples are to be replaced immediately. Press the specified lubricating

grease through the nipple until all the old grease has been evacuated.

Operating and Maintenance Manual

Snow groomer BISON

238

(255)

15 - AUTOMATIC Winch

BISON 908930245 - 30367

15.8.4

15.8.5

Loading...

Loading...