-85-

6. Troubleshooting

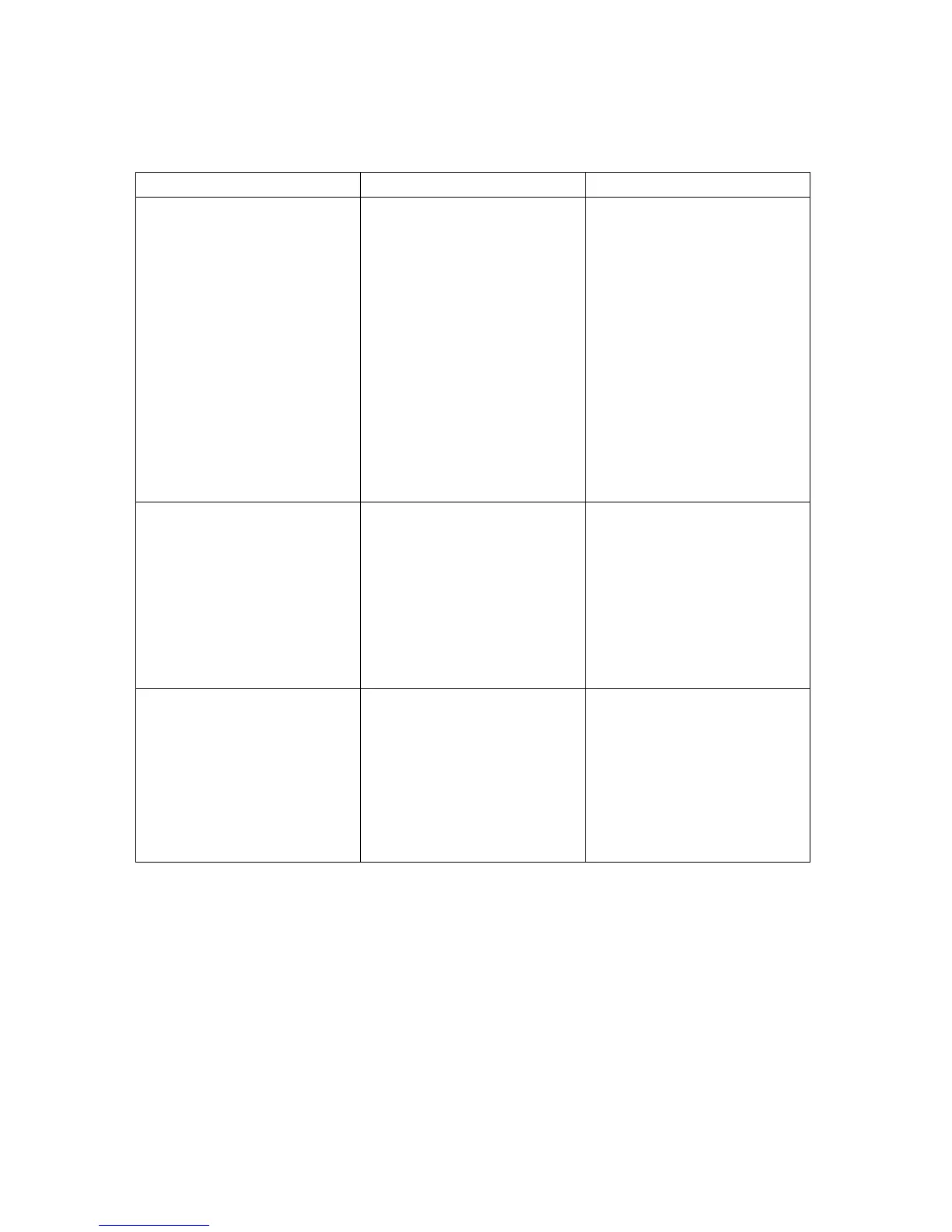

6.1. Maintenance Module (aka Service Station) Troubleshooting The following table lists some

possible problems related to the maintenance module, with possible causes and solutions.

• Jammed gear train from

broken post or improperly

seated gears

• Squeegee (doctor blade)

wedged, not seated

properly

• Debris build-up on blade

and rollers, increasing

friction

• Bad motor

Check through each

of the possible

causes.

If possible, correct

the situation. For

example, re-seat the

gears and squeegee,

clean off debris from

blade and rollers.

Re-test.

If motor is still stalled,

contact Customer

Service

• Wiper roller (microfiber

roller (MFR)) is

saturated

• Squeegee (doctor blade)

wedged, not

seated properly, or is

bowed

If wiper roller is

saturated, replace it.

If squeegee is not

seated properly,

reseat it.

If squeegee is bowed,

contact Customer

Service

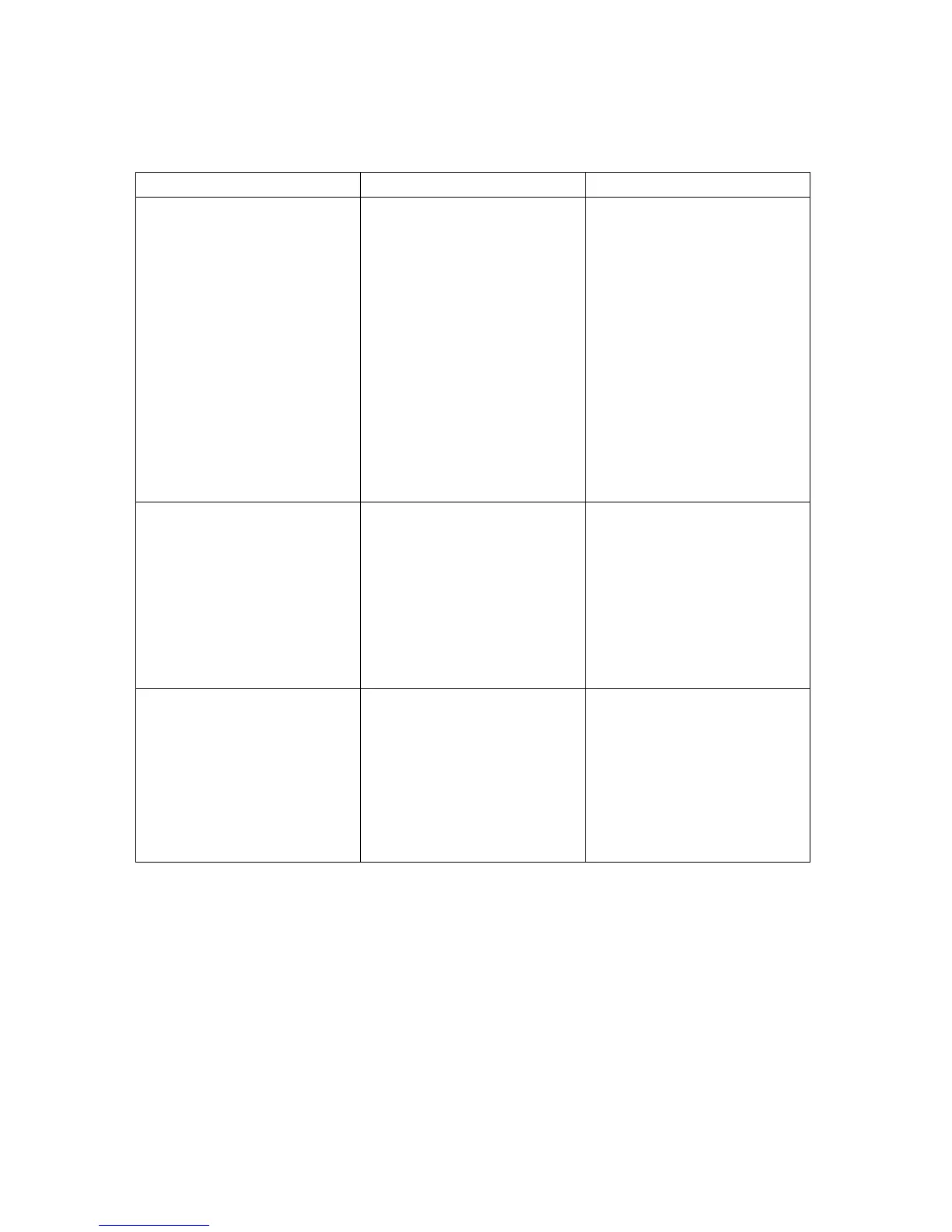

Unable to remove

maintenance module from

the print engine

Latches on the

maintenance module were

not completely closed

when the MM was

inserted and they are now

hooked on the bottom of

the paper path

Contact Customer Service or

your Application Engineer

Loading...

Loading...