MACHINE DESCRIPTION

UM-PSPC-06-E/10-2012 USER MANAUL PSPC Page 27 of 99

UNIT DESCRIPTION

PACKER

Use:

The Packer is designed to receive a random

supply of eggs and assemble these eggs into

fixed patterns of 25, 30, 36 or 42 eggs and

place them with the pointed end downwards

into a tray.

Construction:

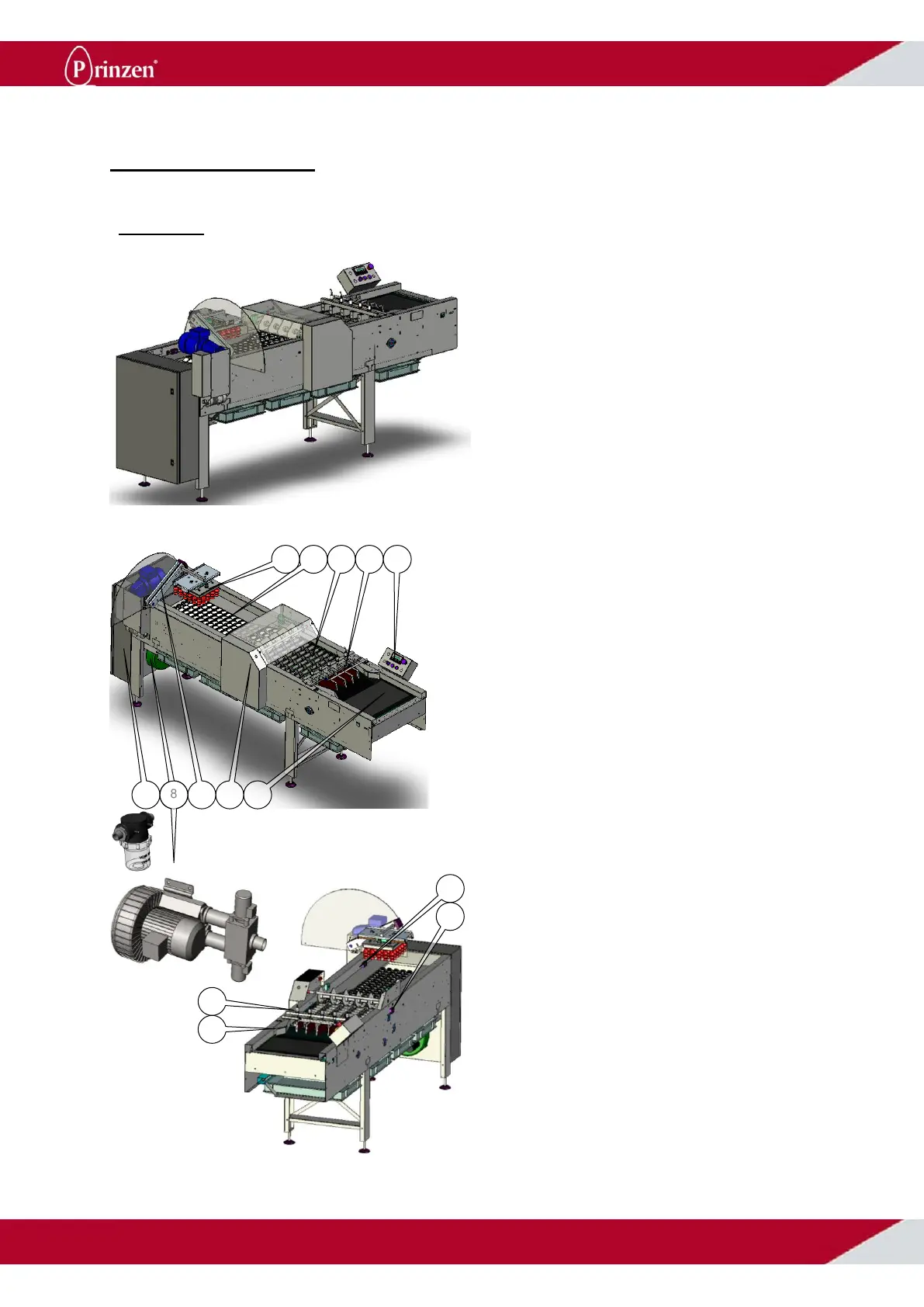

The packer consists of:

1 Infeed conveyor

2 Infeed gate

3 Main drive

4 Roller track

5 Cup conveyor

6 Transfer lever

7 Vacuum head

8 Vacuum system

Attached to the packer are:

9 Electrical cabinet

10 Operating panel

Process:

Eggs are entering the packer on the infeed

conveyor where the eggs may be graded. On

this belt oversized-, misshapen-, cracked- or

dirty eggs should be manually removed.

Egg pressure control sensors (20) on the sides

of the infeed conveyor prevent accumulation of

eggs on the infeed conveyor.

The eggs run into the infeed gates where they

are detected (21). When all gates have

detected an egg, the roller track moves one

step forwards receiving the eggs from the

gates in between 2 rollers on the roller shafts.

Because of the shape of the rollers and their

rotating movement, during each step forwards,

the eggs move with their pointed ends more

towards the outside of the rollers.

At the main drive position, the egg lifters lift the

eggs on the round end up while flaps are

guiding the pointed end into the cups of the

cup conveyor.

A cup detection sensor (22) stops the system

when remaining eggs are detected in between

the roller track and the cup conveyor.

The cup conveyor transports the eggs towards

the transfer lever position until the first line of

eggs is detected by the start transfer sensor

(23).

The vacuum head on the transfer lever moves

down to pick up the eggs and transports them

towards an empty tray on the outfeed

conveyor.

Loading...

Loading...