In the case of stationary use, the device is usually installed downstream of the dryer/filter,

enabling the entire system to be monitored. It may also be installed at any point further

downstream in the distribution system in order to

monitor subsegments or the air supply entering a

particular machine.

In order to avoid unnecessary compressed-air

consumption through loss of scavenging air, the

measuring chamber with the sensor should preferably

be directly installed into the compressed-air line.

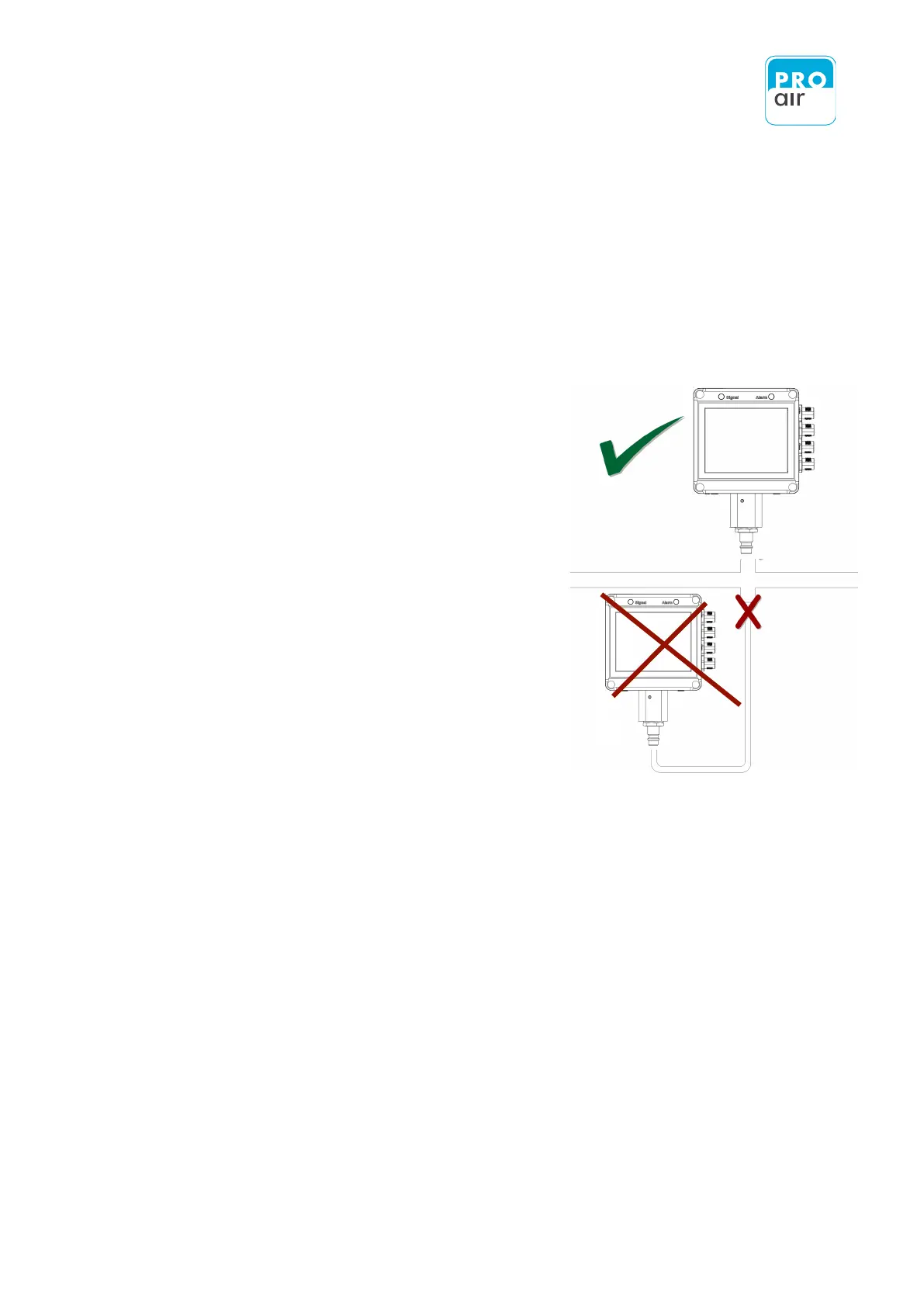

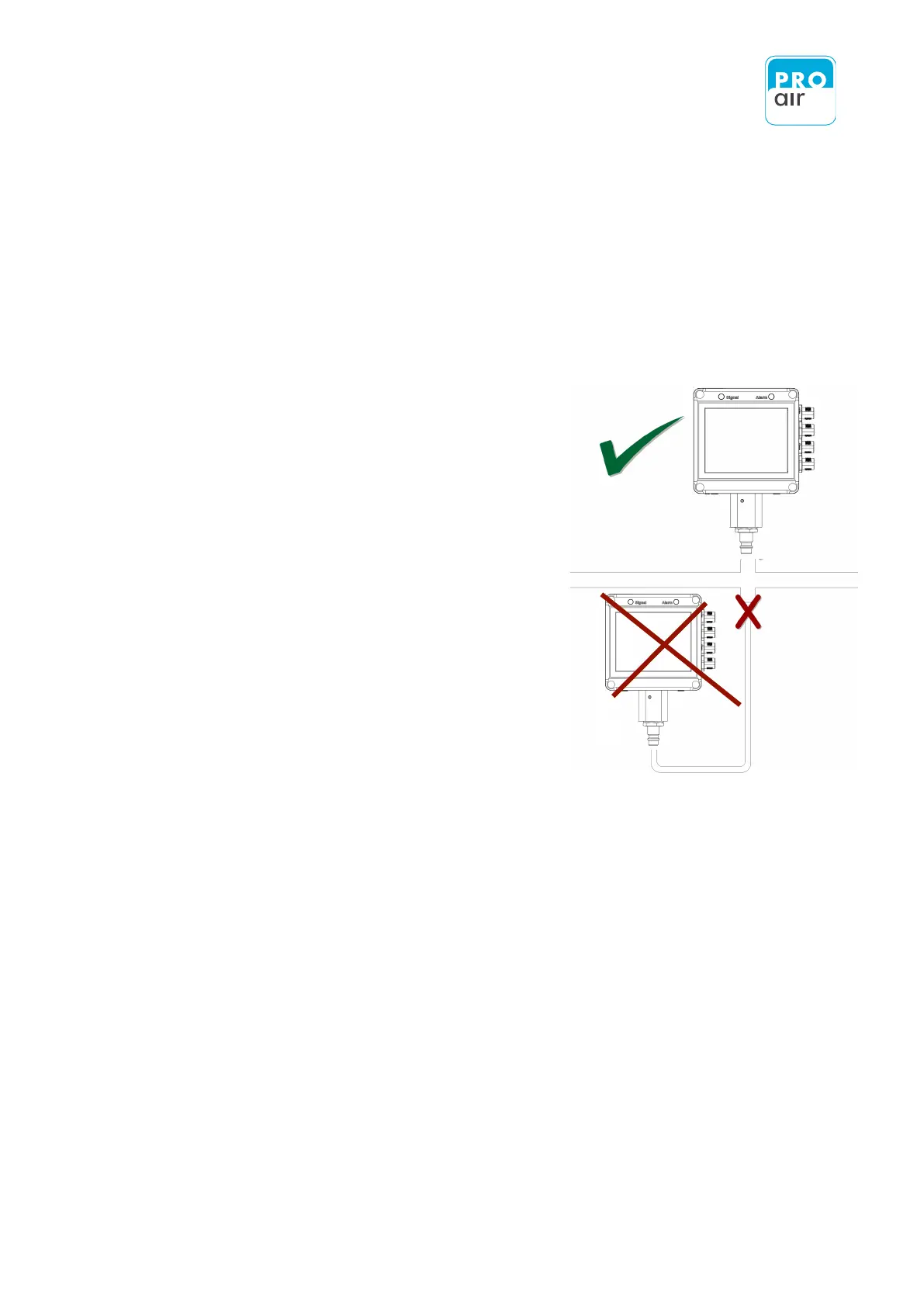

To prevent the accumulation of condensation in the

event of a fault, the measuring chamber must be

screwed vertically into the line from the top.

Extremely high flowrates or sudden pressure changes

should be avoided, as these may damage the sensor

element.

If a spur line is required for connection, this should

only be a few centimetres long, otherwise the

response will be impaired, especially at low dew-point

values. If longer spur lines are used, the choke must be opened onto the measuring chamber

and set to approximately 60 l/h.

Long, vertical spur lines impair the response or result in incorrect measured values.

The device may be alternatively connected to the compressed-air supply via a Teflon connection

line through the built-in measuring chamber with choke. To ensure correct functioning and

guarantee measuring accuracy there must be a throughflow of air. The basic flow rate can be set

at the choke. In order to avoid unnecessarily high loss of scavenging air, the flow at the rated

pressure can be set to 60 l/h by means of a flow meter. Check from time to time that there is air

flowing at the adjusting screw. If the choke is closed, the measuring device displays values that

are too high or triggers an alarm

Loading...

Loading...