© 2015 Proceq SA 21

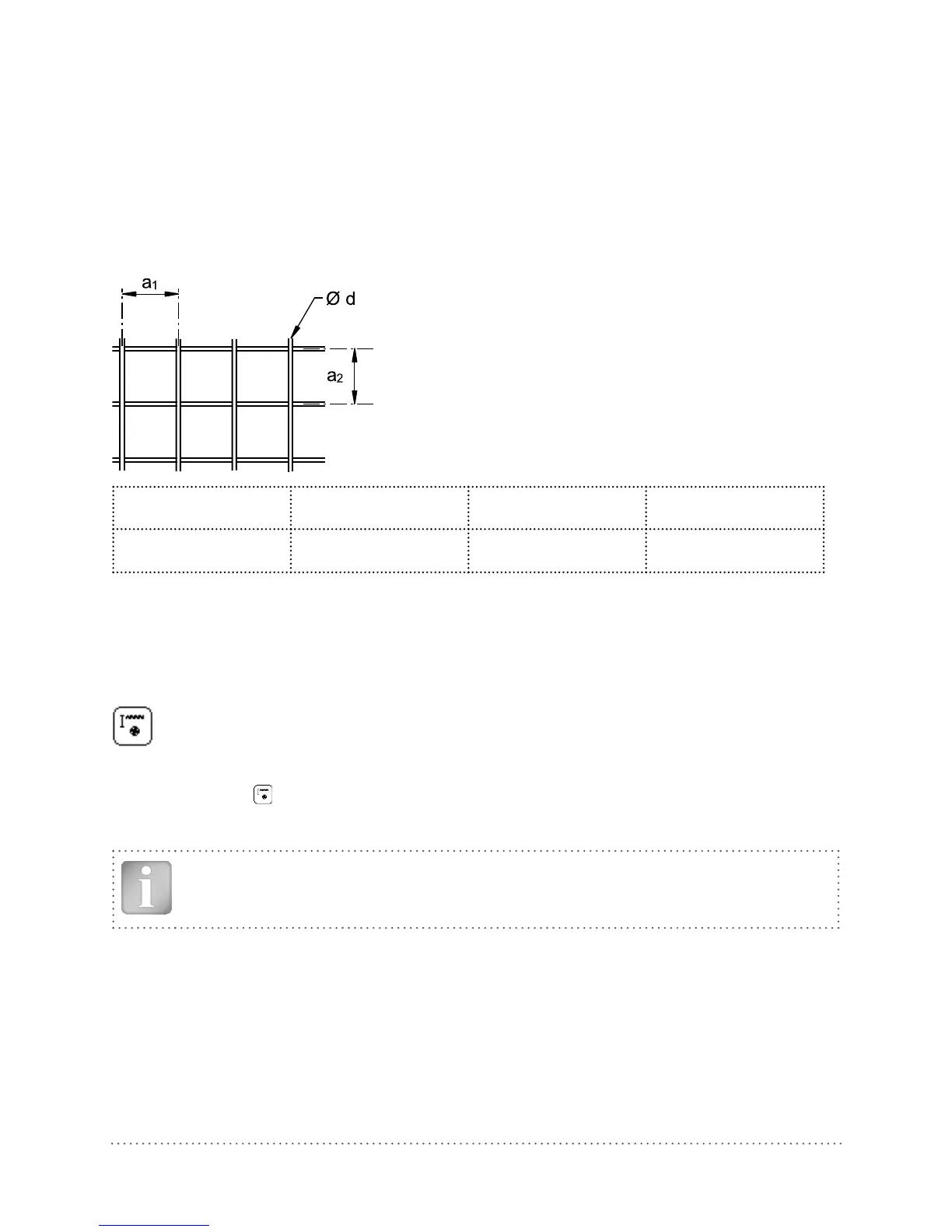

5.3.3 Measurements over Welded Reinforcement Meshes

The instrument cannot detect whether the rebars are welded to one another or connected with bind-

ing wires. The two reinforcement types with the same dimensions however create different signals.

The setting of the bar diameter must be slightly higher than the actual diameter of the mesh rebar.

The input depends on the bar diameter and on the mesh spacings. This input value should be

determined by means of a test on an open system with specific rebar mesh wire arrangements.

Measure on each arrangement with different covers to find out the diameter setting at which the

correct cover is indicated.

Welded reinforing mesh

a

1

[mm]

a

2

[mm]

current d

[mm]

d to be set

[mm]

100

150

100

150

5

6

8

7

Fig 26: Examples for diameter settings at welded mesh

Select the “Standard” measuring range. The “Large” measuring range cannot be used with welded

reinforcing meshes. Locate and measure the cover as explained in the previous chapters.

5.3.4 Minimum Cover Alert

This is particularly useful for detecting insufficient concrete cover depth when conducting

large scale checks on structures after removing the formwork or large scale building inspec-

tions and so forth.

Enter the settings menu, select the icon and set the required cover depth limit. Verify that minimum

cover alert symbol is active in the status line at the top of the display.

Move the Profoscope over the test surface. Whenever the cover depth is less than the programmed

minimum the LED Indicator will light and if it is enabled, an acoustic alarm will be given.

NOTE! In this mode the LED will not light to indicate that a rebar has been located.

Loading...

Loading...