© 2015 Proceq SA 7

3. Tutorial

3.1 The Measurement Principle

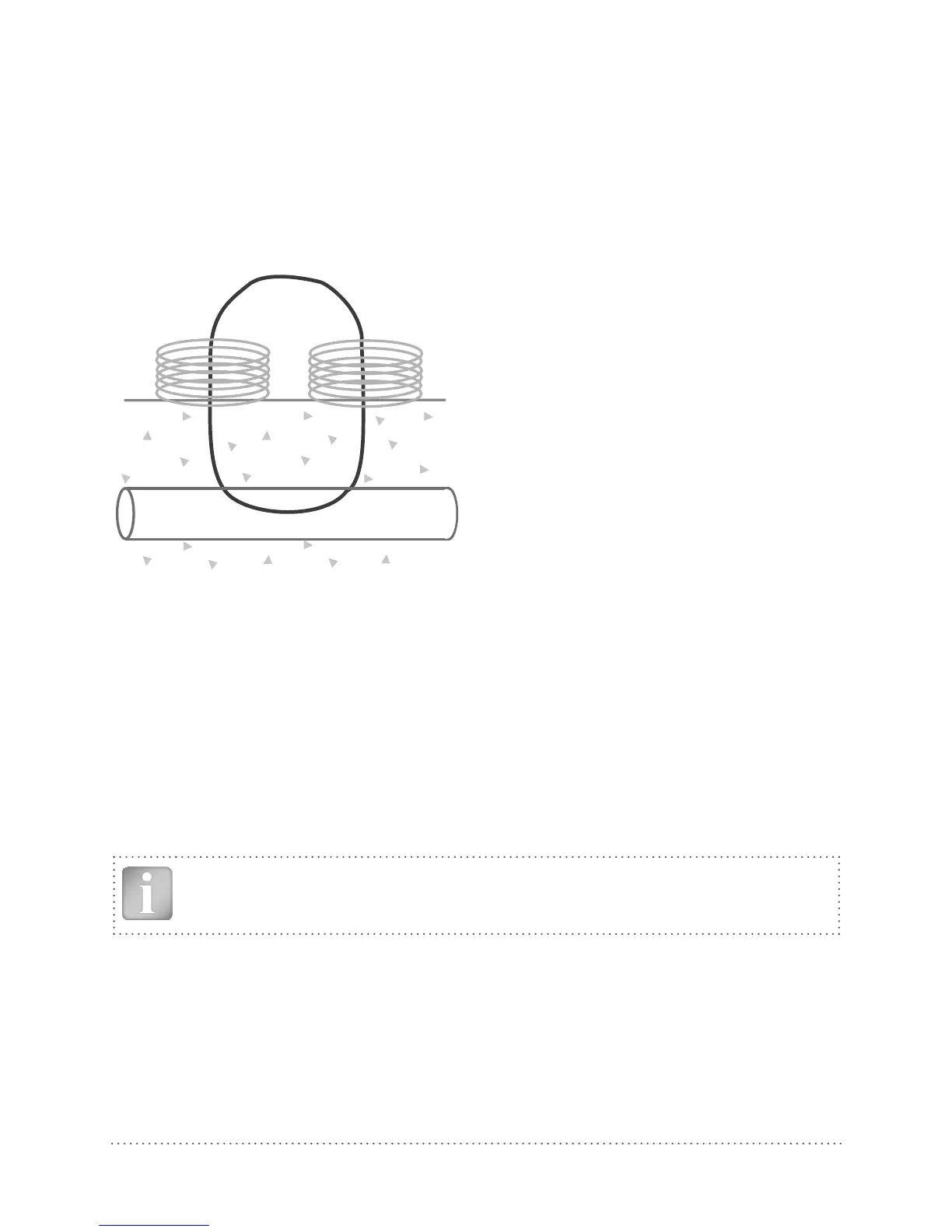

The Profoscope uses electromagnetic pulse induction technology to detect rebars.

Coils in the probe are periodically charged by current pulses and thus generate a magnetic field.

On the surface of any electrically conductive material which is in the magnetic field eddy currents

are produced. They induce a magnetic field in the opposite direction. The resulting change in volt-

age can be utilized for the measurement.

Coils

Concrete

Rebar

Magnetic Field

Fig 3: Measurement principle

The Profoscope uses different coil arrangements to generate several magnetic fields. Advanced

signal processing allows

1. Localization of a rebar

2. Localization of the mid-point between rebars.

3. Determination of the

cover

4. Estimation of the bar diameter

This method is unaffected by all non conductive materials such as concrete*, wood, plastics,

bricks etc. However any kind of conductive materials within the magnetic

field

(approx. 400 mm /

16” sphere) will have an influence

on

the measurement.

* Some concrete types and other structural materials may have metallic content.

NOTE! Remove all metallic objects such as rings and watches before you start measuring.

3.2 Calibrated Measuring with Profoscope

The Profoscope is calibrated to measure on a normal rebar arrangement; which is an arrangement

of non-stainless steel rebars fastened with binding wires only. E. g. when measuring on welded

mesh wires the cover and diameter readings must be corrected (see 5.3.3 and 5.4.5). The following

information on accuracy, measuring ranges and resolutions refer to measurements on such normal

rebar arrangements.

Loading...

Loading...