© 2015 Proceq SA 23

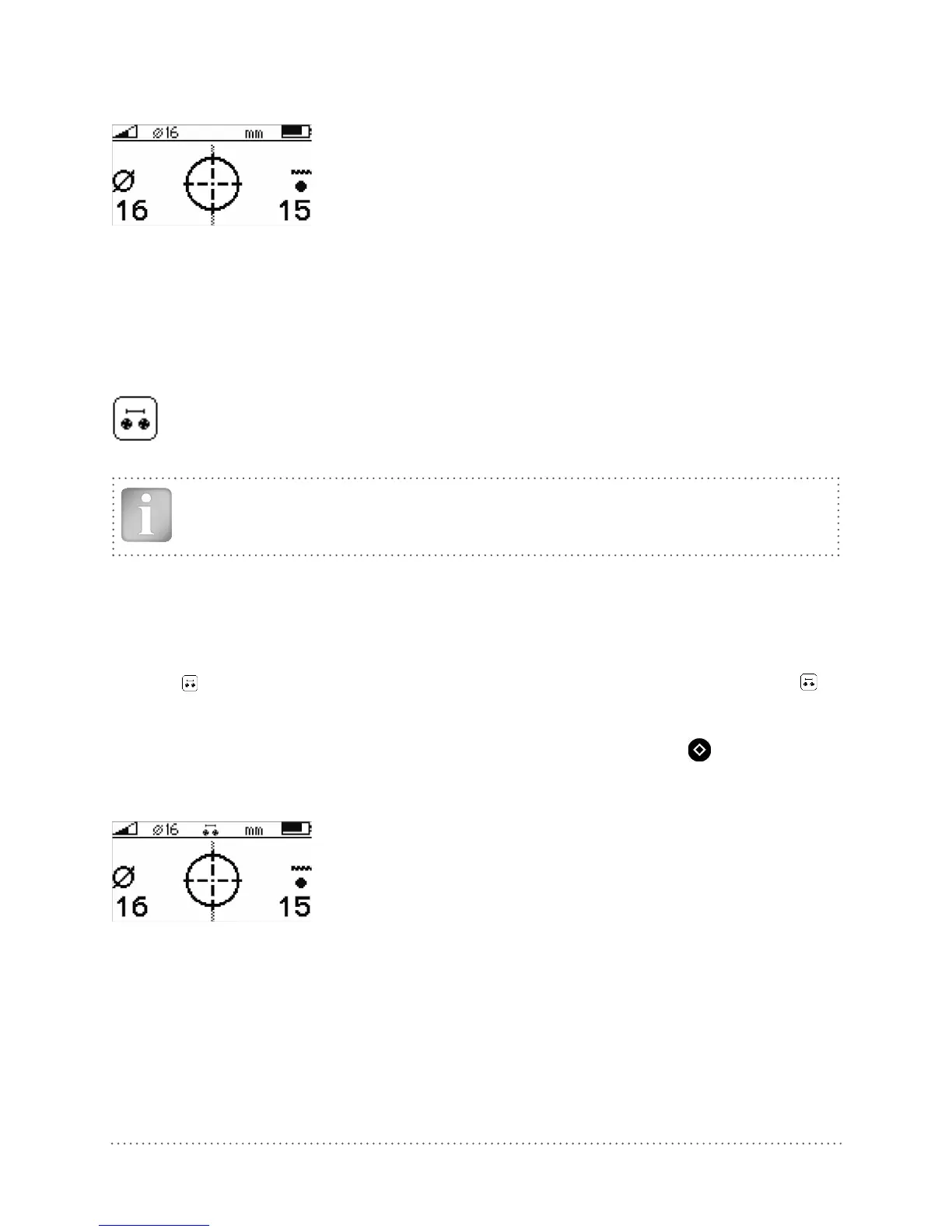

The measured rebar diameter appears for a few seconds instead of the signal strength arrow on the

bottom left corner of the display.

Fig 28: Display of measured diameter

Note down the rebar diameter. With the Profoscope+ you may also store the measured diameter

(see 6.8.1).

5.4.2 Diameter Measurement on Areas with insufficient Spacing of the Rebars

(Neighboring Rebar Correction)

Method 2

As described in the tutorial neighboring rebars that are within the sphere of influence will also

be detected by the Profoscope and will affect cover depth and diameter estimation results.

A insufficient spacing is smaller as the minimum spacing defined in 3.4.4.

The effects of neighboring rebars can be mitigated by keying-in a correction value.

NOTE! This works only for rebars of the same layer running in parallel to the rebar under

test.

Step 1 Create a rebar as described in 5.2.4.

Step 2 Select one rebar that has the largest spacing from neighboring rebars.

Step 3 Use a ruler to measure the spacing. In case the spacing from the rebar under test to a

neighboring rebar is equal or less than 130 mm / 5.2” go to the main menu, select the icon

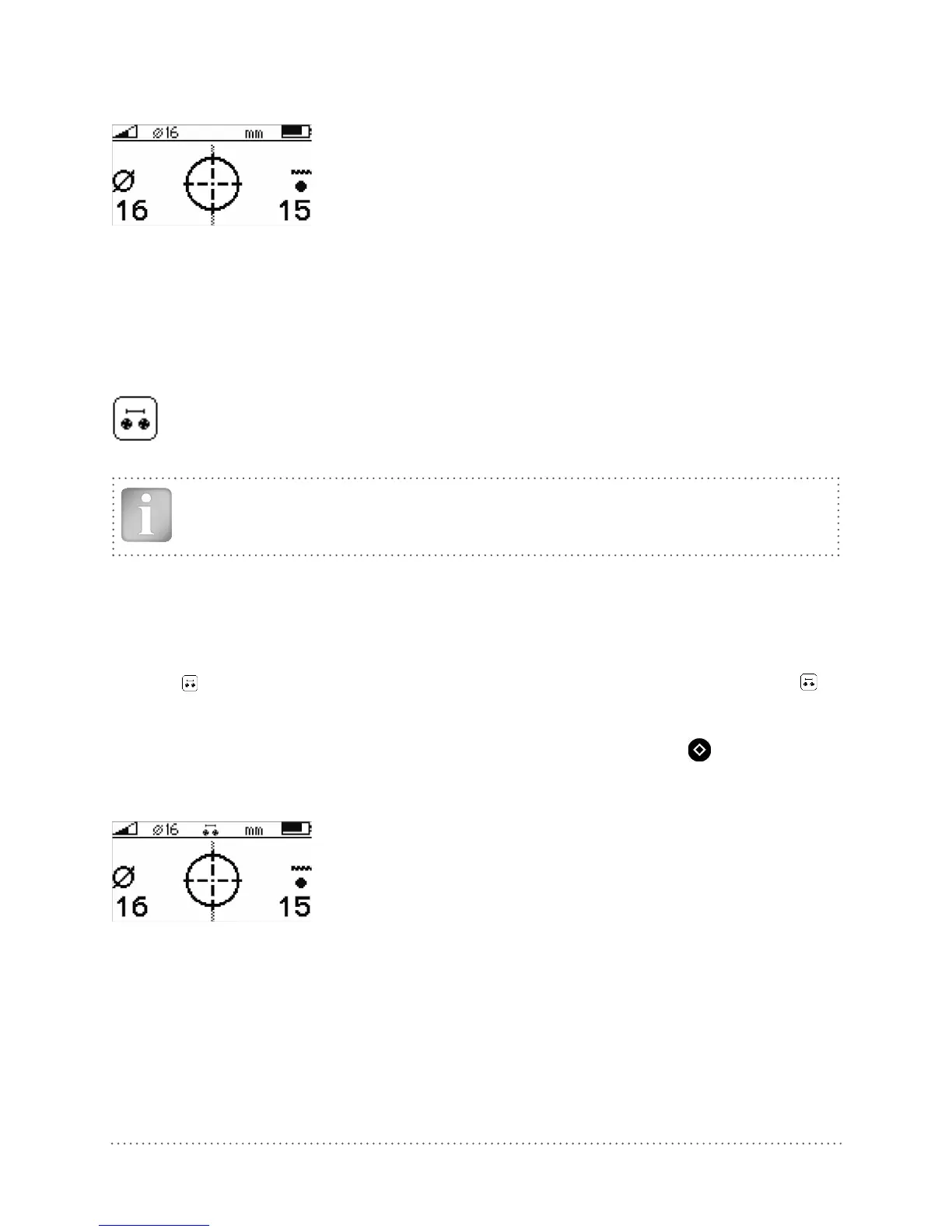

and input the measured spacing. Verify that neighboring rebar correction symbol is

active in the status line at the top of the display.

Step 4 Place the MC (4) of the Profoscope over the rebar at the midpoint line of the rebars run-

ning crosswise to the rebar under test and click the Function Key (6)

on the left side.

The measured rebar diameter appears for a few seconds instead of the signal strength arrow on the

bottom left corner of the display.

Fig 29: Display of measured diameter with neighboring rebar correction set

Note down the rebar diameter. With the Profoscope+ you may also store the measured diameter

(see 6.8.1).

Try it out on the start-up test kit.

Loading...

Loading...