Quantech

120

Form QTC3-NM1

Issue date: 12/19/2023

Section 6: Commissioning

fore placing the unit back in service, valves should be

opened and power must be switched ON (if power is

removed for more than 8 hours) for at least 8 hours (24

hours if ambient temperature is below 86°F [30°C])

before the unit is restarted.

Sporlan EEV interface board

Verify the jumper and dip switch settings, Figure 38 on

page 119, during a chiller start-up for QTC3 and QWC3

chillers with Sporlan Electronic Expansion Valves.

With the IB-G unpowered, select the input signal of 0

V to 10 V by installing the supplied jumper to number

1 of the 5 pin locations shown in the left hand side of

EEV board. Set numbers 1 to 3 of the DIP switches in

accordance with the unit models. Set numbers 4 to 8 in

accordance with the table shown in Figure 38 on page

119. For QTC3 chillers, DIP switch number 6 must be

set to ON for a quicker EEV response.

F/ protection

Verify all sources of electrical supply to the unit are

taken from a single point of isolation. Check that the

maximum recommended fuse sizes given in Section 5:

Technical data has not been exceeded.

Preparation, with power on

Perform the commissioning using the de-

tailed checks outlined. Refer to the Equip-

ment Pre-Startup And Startup Checklist

(Form 150.72-CL1) as the commissioning

procedure is carried out.

Apply power to the chiller. Turn on the option panel

circuit breaker if supplied.

The machine is now live!

Low switch

Verify a chilled water flow switch is correctly fitted in

the customer’s piping on the cooler outlet, and wired

into the control panel correctly using shielded cable.

There should be a straight run of at least 5 pipe diam-

eters on either side of the flow switch. The flow switch

should be connected to terminals 13 and 14 of XTBC1

on the panel.

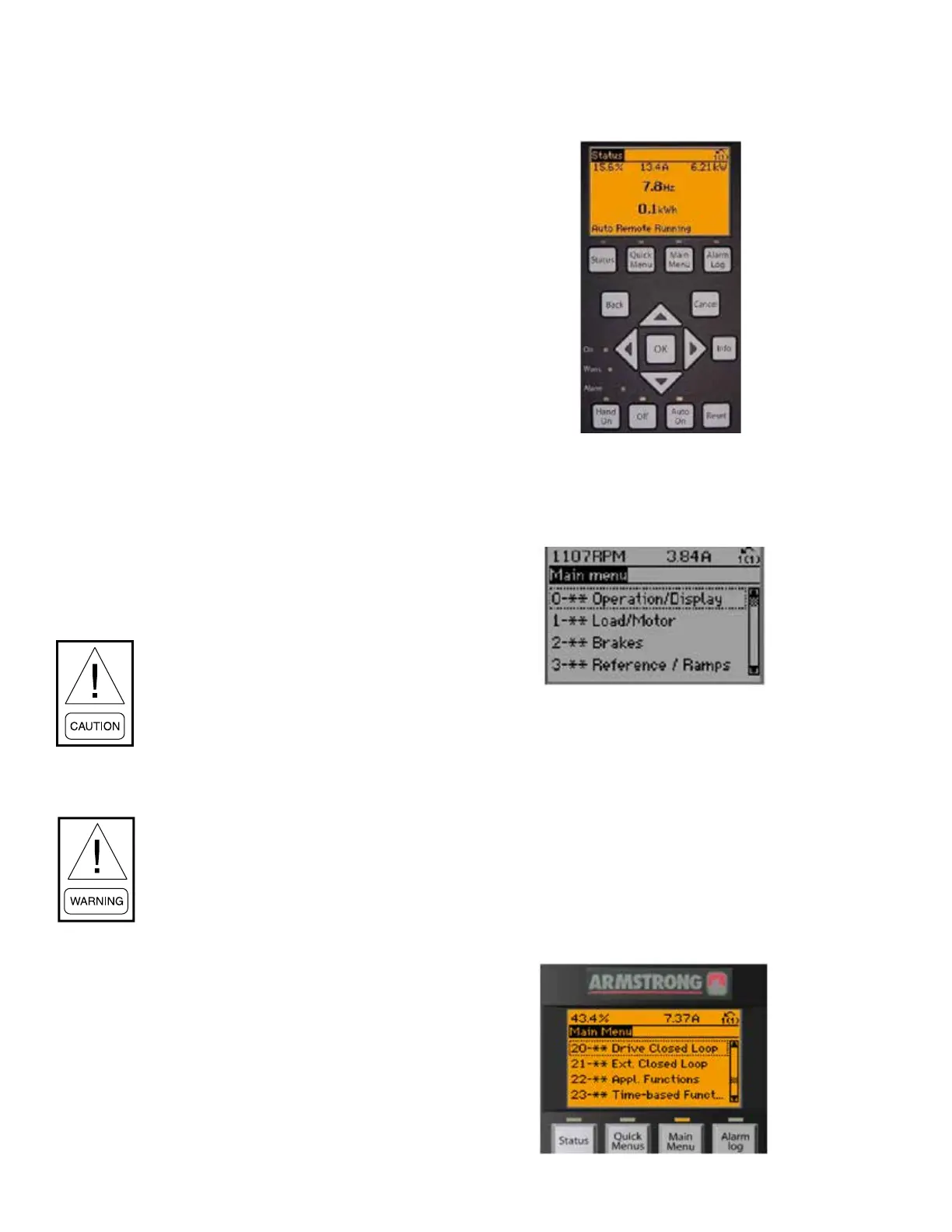

Commissioning the pump VFD

1. Put pump in HAND mode.

LD18418

2. Change parameter 0-20 (default value is option

1601 – “Reference [Unit]”) to option 1850 “Sen-

sorless Readout” to display Sensorless ow read-

out on top le corner of screen.

LD18419

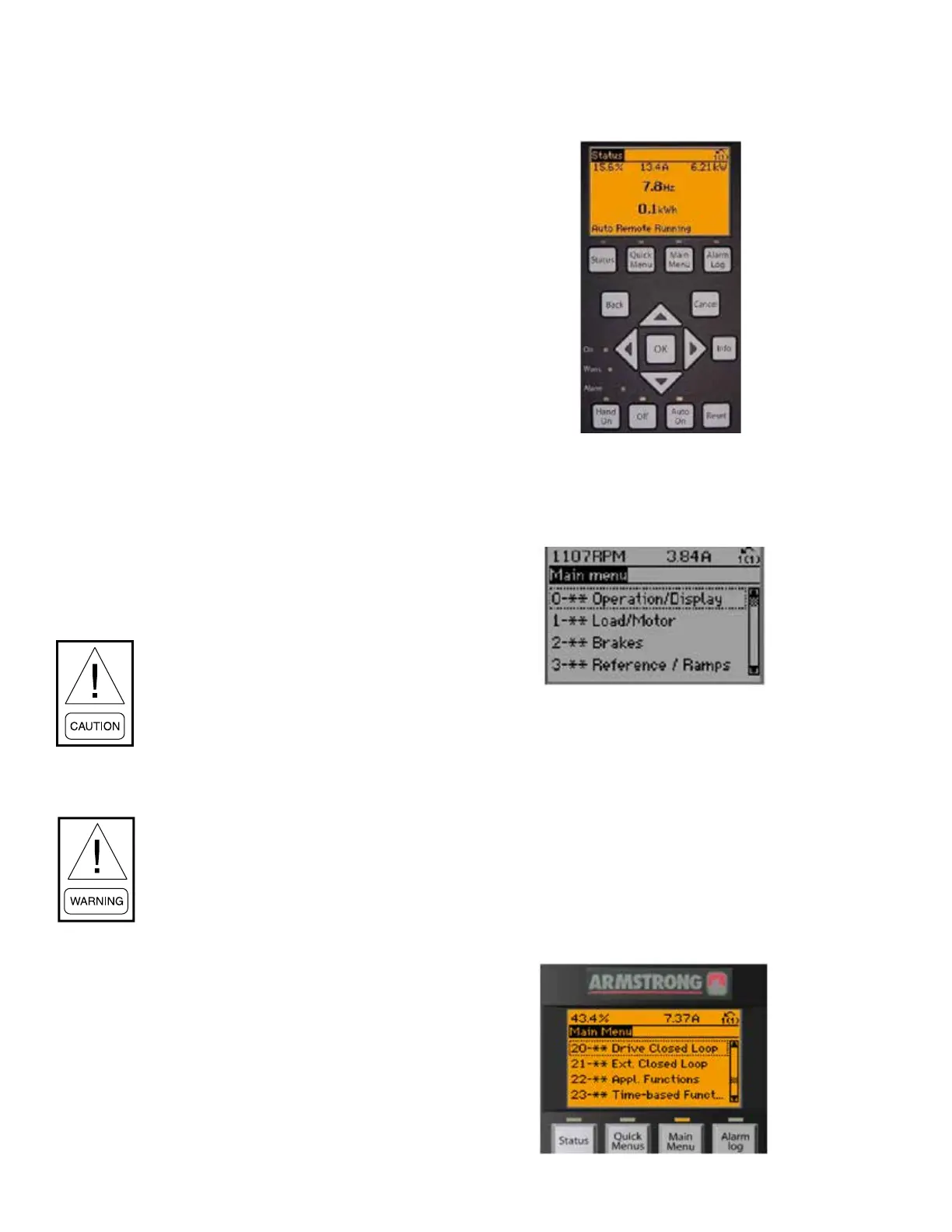

3. Change parameter 0-22 (default value is option

1610 – “Power [kW]”) to option 1654 “Feedback

1 [unit]” to display Sensorless pressure readout on

top right corner of screen.

4. Check with customer regarding new actual ow

and head and verify what ow is required. Ramp

the pump up or down to achieve requested ow.

Record the VFD sensorless ow and pressure –

this will be your new setpoint.

5. Set parameter 20-21 to the Sensorless Pressure

readout taken in the previous step.

LD18420

Loading...

Loading...