Quantech

194

Form QTC3-NM1

Issue date: 12/19/2023

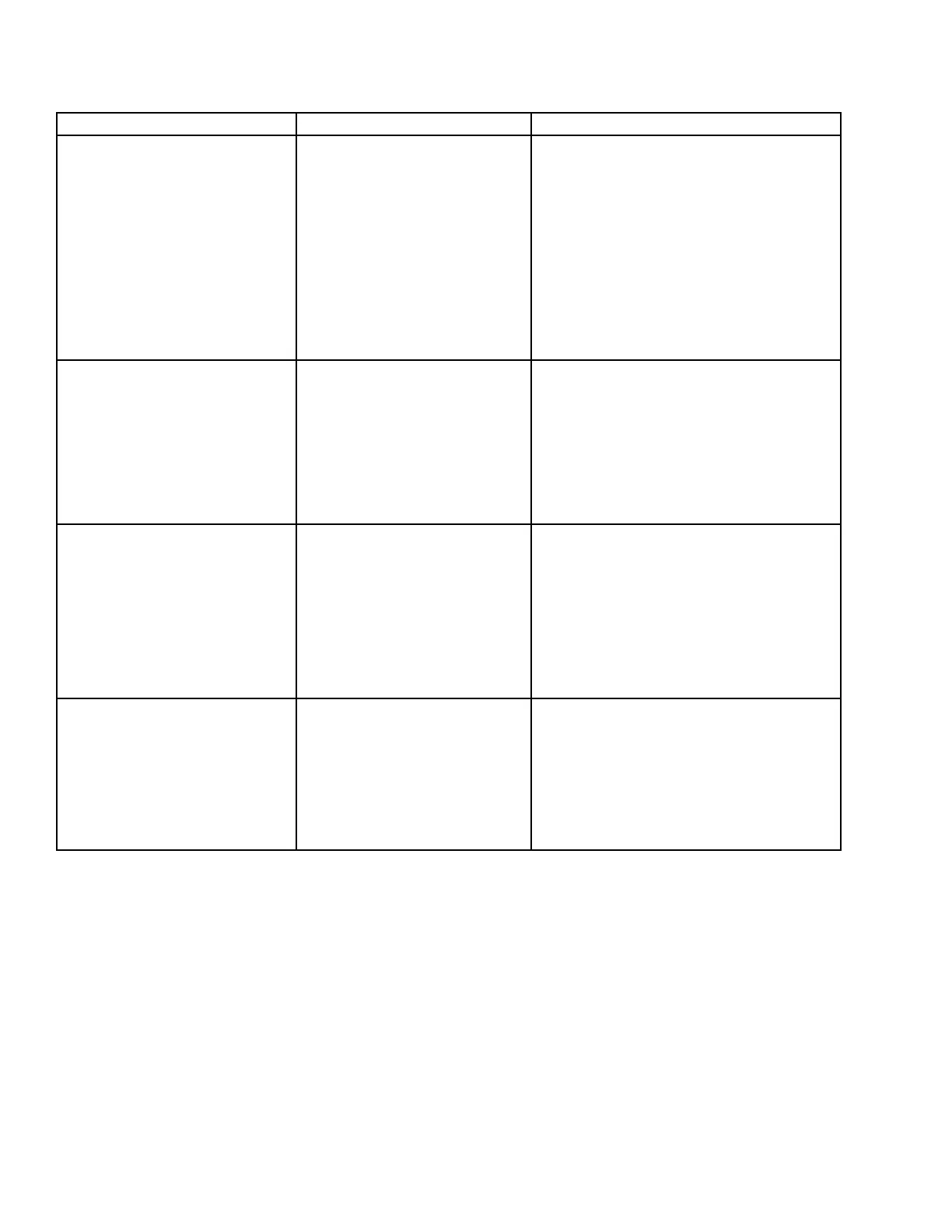

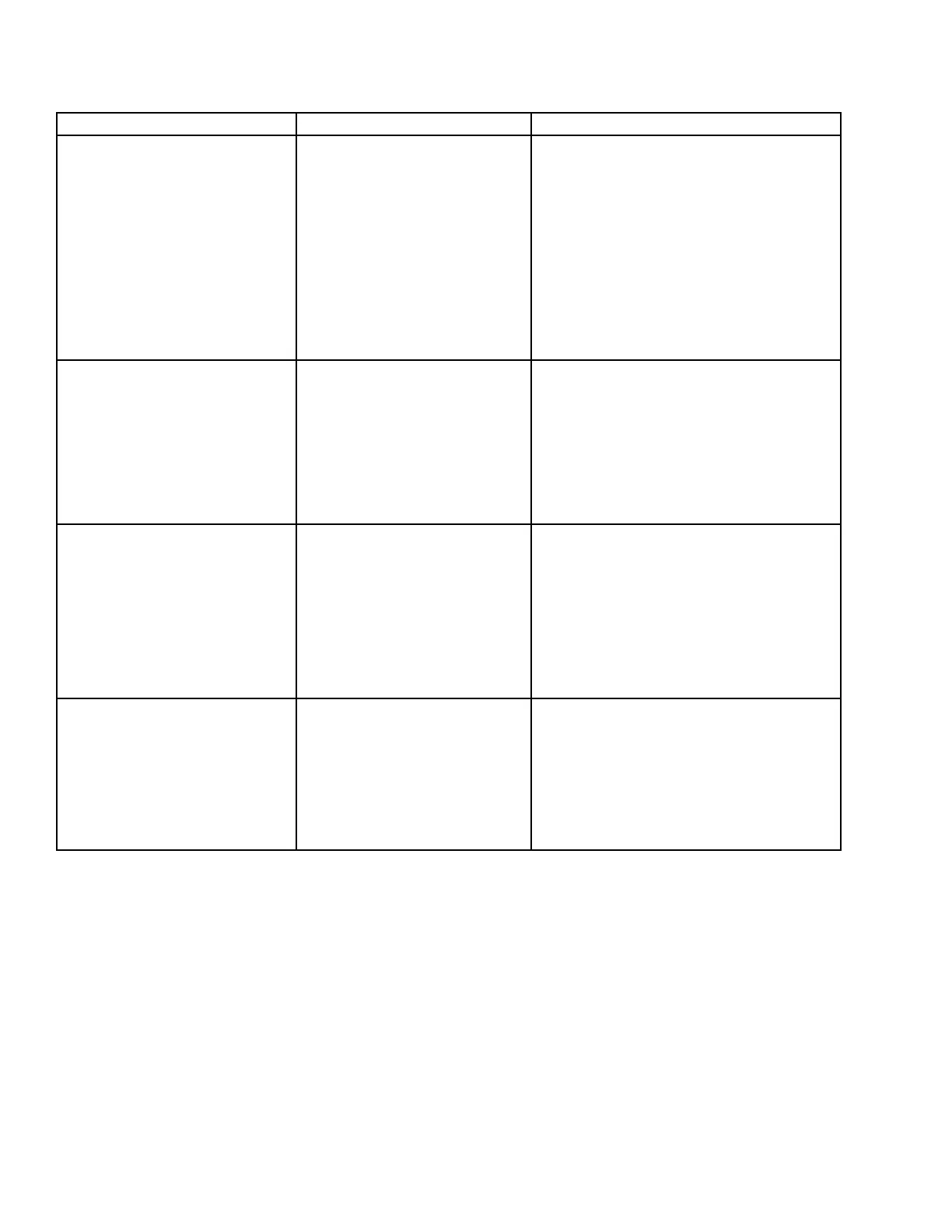

Section 9: Service and troubleshooting

Problem Cause Solution

Low liquid temp fault

1. Improperly adjusted leaving

chilled liquid temp. cutout (glycol

only).

1. Re-program the leaving chilled liquid temp.

cutout.

2. Micro panel setpoint/range

values improperly programmed.

2. Re-adjust setpoint/range.

3. Chilled liquid ow too low.

3. Increase chilled liquid ow. See Operational

limitations on page 47).

4. Defective LWT or RWT sensor

(ensure the sensor is properly

installed in the bottom of the well

with a generous amount of heat)

conductive compound).

4. Compare sensor against a known good

Temperature sensing device. See Table 32

on page 186.

Mp / hpco fault

1. Compressor internal motor

protector (MP) open.

1. Verify refrigerant charge is not low. Verify

superheat setting of 10°F to 15°F (5.6°C to

8.3°C). Verify correct compressor rotation.

Verify compressor is not overloaded.

2. External overload tripped. 2. Determine cause and reset.

3. HPCO switch open. 3. See High Press. Disch. Fault.

4. Defective HPCO switch. 4. Replace HPCO switch.

5. Defective CR relay. 5. Replace relay.

Compressor(s) won’t start

1. Demand not great enough. 1. No problem. Consult Installation Manual to

aid in understanding compressor operation

and capacity control.

2. Defective water temperature

sensor.

2. Compare the display with a thermometer.

Should be within plus or minus 2 degrees.

See Table 32 on page 186 for RWT/LWT

temp./voltage table.

3. Contactor/Overload failure. 3. Replace defective part.

4. Compressor failure. 4. Diagnose cause of failure and replace.

Lack of cooling eect

1. Fouled evaporator surface.

Low suction pressure will be

observed.

1. Contact the local Quantech service

representative.

2. Improper ow through the

evaporator.

2. Reduce ow to within chiller design specs.

See Operational limitations on page 47).

3. Low refrigerant charge. Low

suction pressure will be

observed.

3. Check subcooling and add charge as

needed.

Table 35: Troubleshooting, continued

Loading...

Loading...