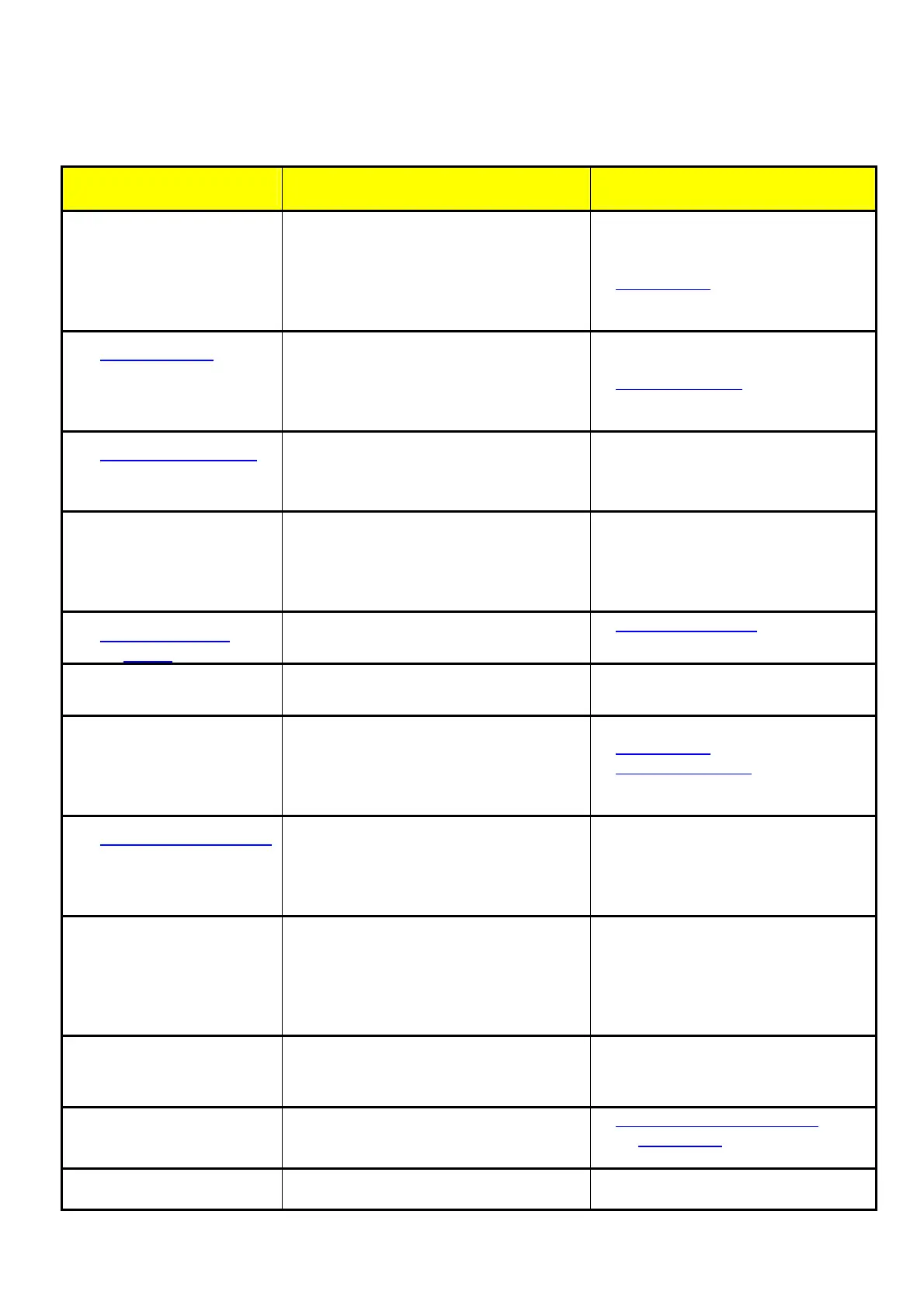

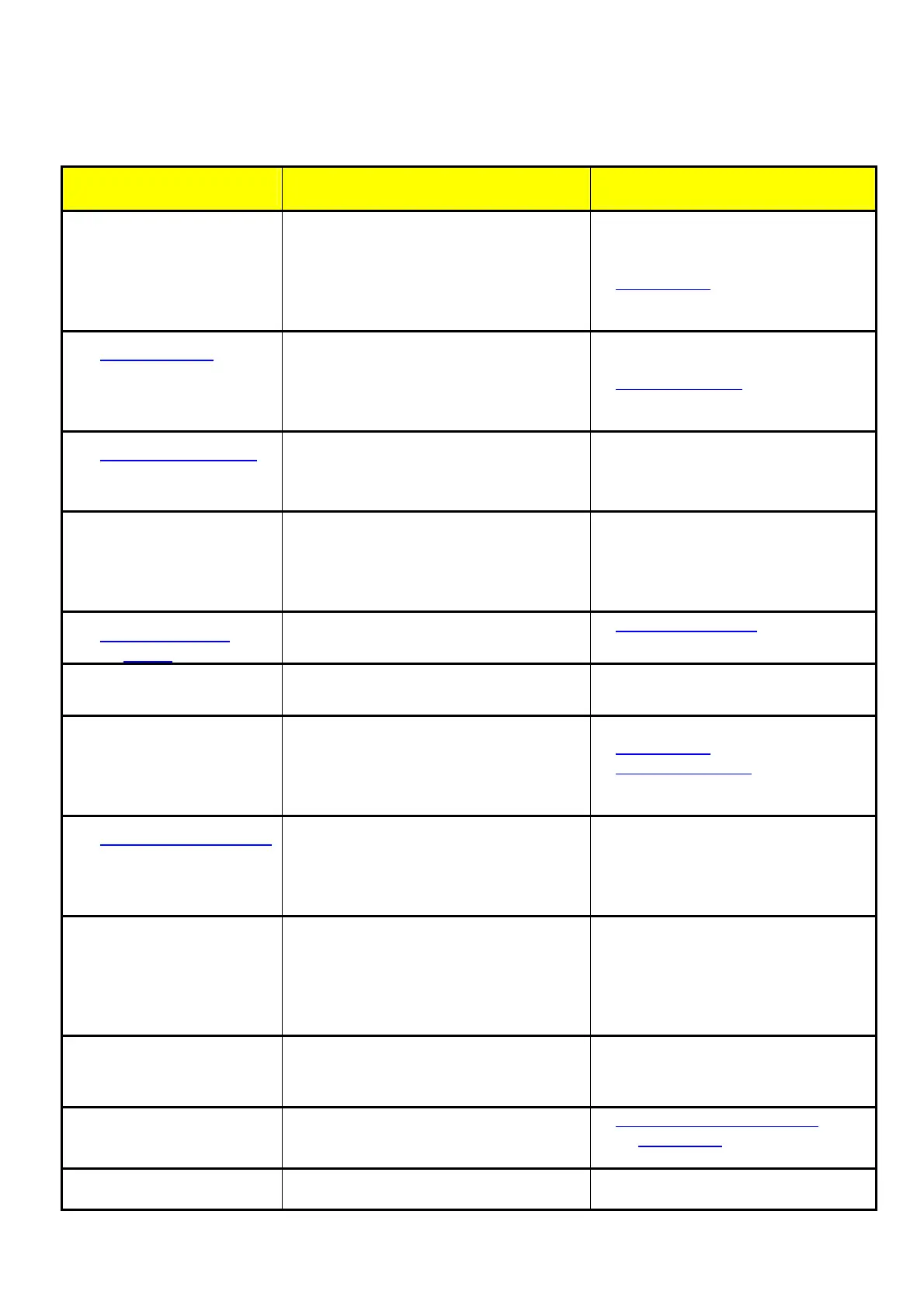

11.1.2 Customer experience

Problem description: Possible reason: Solution:

0 too low engraving

depth

Ò imprecise focusing

Ò dirty optics

Ò table misaligned

Ò too low laser power

Ò dirty beam output window on tube

check focus

¬ clean optics

¬ check table adjustment

¬ replace tube

¬ clean output window

0 blurred edges

Ò imprecise focusing

Ò table misaligned

Ò incorrect Alignment settings

(Overtook)

¬ check focus

¬ check table adjustment

¬ adjust Alignment

0 bad shoulder angle

Ò table misaligned

Ò defect electronic board

Ò bad shoulder settings

¬ check table adjustment

¬ replace board

¬ improve shoulder settings

0 missing cut lines

Ò 0 passes in driver or JobControl

selected

Ò line thickness in Corel Draw too big

Ò color is skipped

¬ increase the amount of passes

¬ reduce line thickness to smallest

possible value

¬ Set to cutting

0 shadows on the

edges

Ò tickle power too high ¬ adjust tickle power

0 Shadows between

letters

Ò Tickle delay too low ¬ Adjust tickle delay

0 Inconstant /

alternating

engraving depths

Ò table misaligned

Ò Lasertube is defect / empty

Ò Laserbeam misaligned

Ò Material is not plane (foil)

¬ adjust table

¬ replace tube

¬ adjust Laserbeam

¬ use multimate

0 waviness of the lines

Ò bad THK guide

Ò bad belt tension

Ò too high acceleration settings

Ò Lens is loosen

¬ replace guide

¬ check belt tensions

¬ reduce acceleration

¬ check if lens sticks to lensholder

0 no visible marking

result

Ò too low laser power

Ò too high velocity

Ò not focused

Ò wrong focus tool

Ò damaged lasertube

¬ increase power setting

¬ reduce velocity

¬ check focus

¬ change focus tool

¬ change the lasertube

0 fine details on

stamps are

engraved too thin

Ò incorrect Edit settings

Ò too steep shoulders

¬ adjust edits

¬ reduce T, increase W

0 not vertical cut edge

Ò beam isn’t in the middle of the lens ¬ _Problems_with_non_right

angled cutt

0 job has not been

Ò connection to machine broken ¬ check the cable connection, the

electronics and the com port

Loading...

Loading...