11.4 Laser Quick Check

The laser quick check is thought for situations where you don’t see an obvious problem, but want

to do check the temporary condition of your machine.

- check the optical components (lens, mirror#1, mirror#2, mirror#3, beam combiner)

- check the grade of soiling (engraving area)

- verify home position

- listen carefully to eventual noise generation

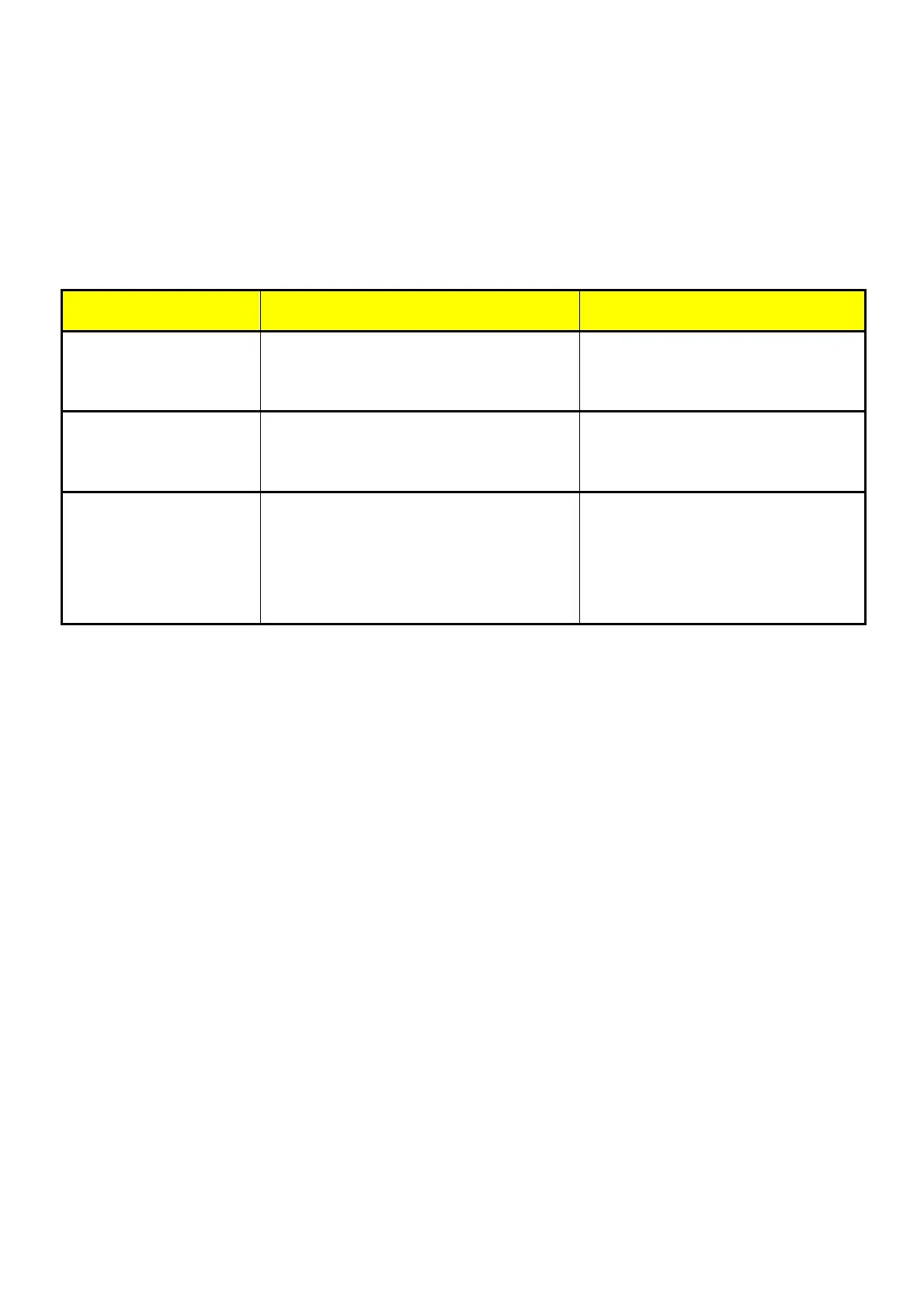

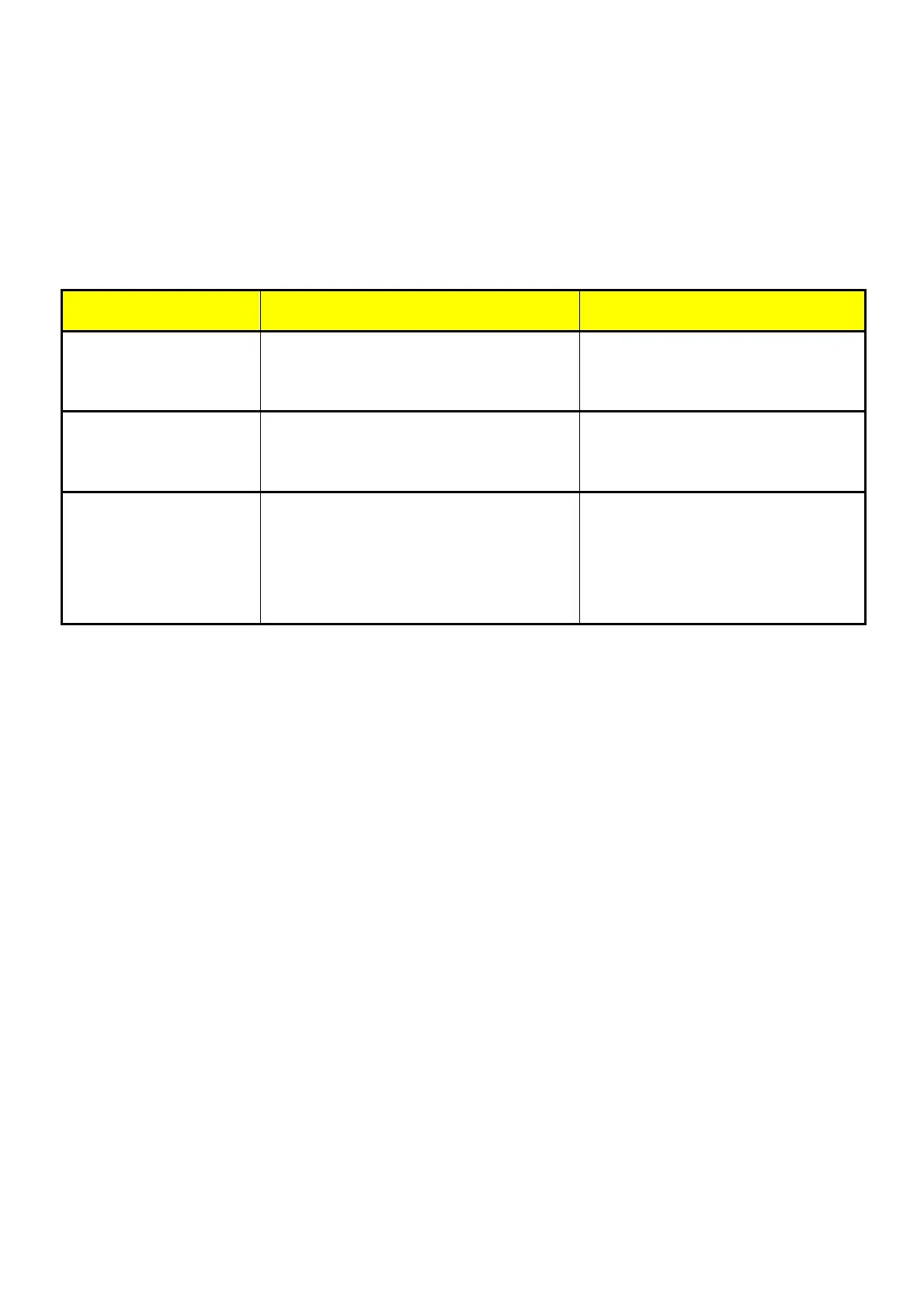

Problem description: Possible reason: Solution:

0 noisy cooling fans

Ò damaged ball bearings

Ò incorrect supply voltage

Ò old fan version

¬ replace fan

¬ wrong fan installed – change it

0 noisy or vibrating

table

Ò old version of the lead screws ¬ Oil and adjust the lead screws

new. If you have no success

change to the redesigned one.

0 Lower laserpower

(less engraving

depth in rubber,

reduced

engraving

speed )

Ò Scratches on the optical components ¬ Change the scratched optics

- classify the engraving quality of your results

- check the laser beam alignment (CO2 laser and red dot )

Loading...

Loading...