Version Number: RBM2000P-20210517A1

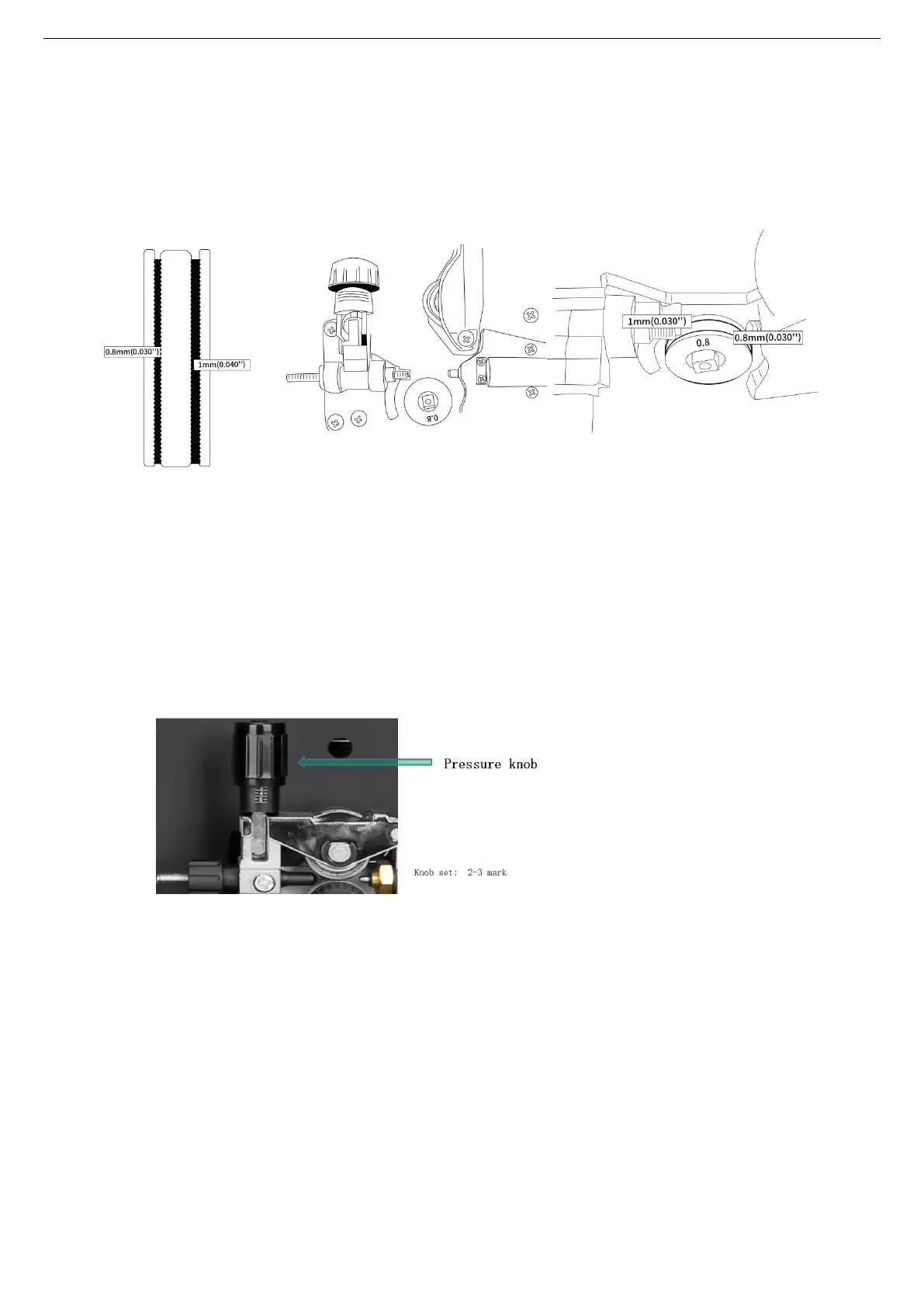

5、Set drive roll

Face the side marked 0.030” away from the machine.

Remarks: 1. There are two grooves on one wire feed wheel, one side is 0.030” (0.8mm) and the other side is

0.040” (1.0mm) to match the corresponding wire diameter.

2. Gas welding requires the use of

Knurl

-type wire feed wheels, which are suitable for ordinary carbon

steel welding wire and stainless steel welding wire, and solid wire welding need to use CO2 gas or

CO2 and Argon gas mixture. Flux-cored wire is not need Protective gas.

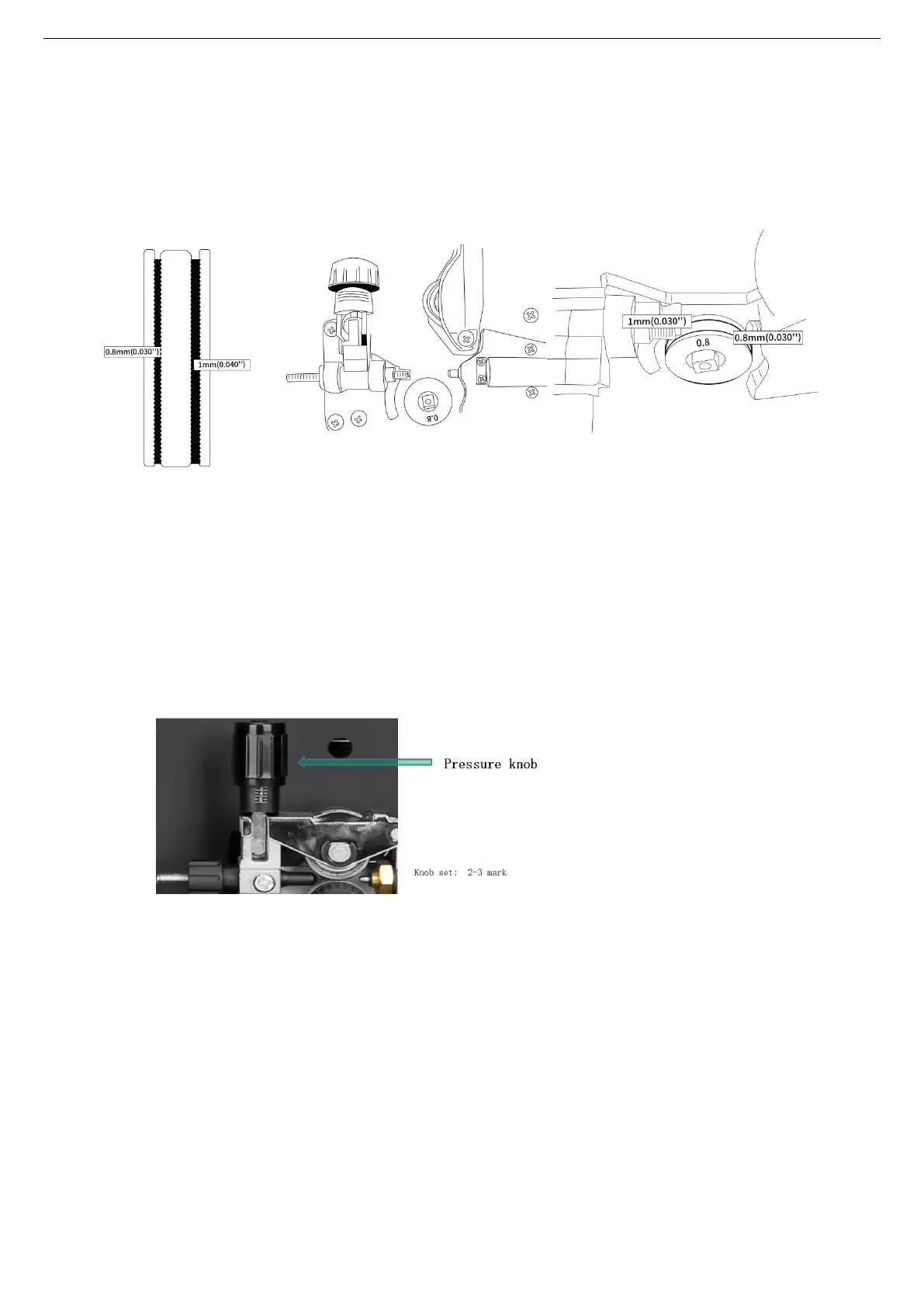

6、Feed wire and set pressure

The pressure should not be too loose, too loose will cause the welding wire to slip and the wire feeding is

unstable, and too tight will cause the welding wire to slip and deform.

7、Connect to Input Power

Please refer to the digital sign on the rear panel of the machine for the input voltage, the input voltage is AC 220V,

the wrong voltage will damage the machine.

8、Please connect CO2 gas, flux cored wire welding does not require the use of shielding gas:

1. Attach gas hose to machine.

2. Attach hose and regulator to gas bottle.

9、Installation of welding torch.

The welding wire should be extended outside the European central socket, and then install the welding torch.

The wire guide tube and contact tip of the welding torch need to match the welding wire. Long press the A knob, This

Loading...

Loading...