Version Number: RBM2000P-20210517A1

(4) Wire detection

Long press knob A, then the welding machine feeds wire fast; release knob A to stop wire feed.

(5) Gas detection

Long press knob B, then the welding machine detects gas; release knob B to stop gas detection.

Second level panel setting interface

Press knob A on the first level panel setting interface, then the welding machine displays “ITEM VRLU” and

nters the second level parameter setting interface. The knob A is used for selecting the parameters and the

knob B is used for adjusting the parameters. See Table 5-2 Comparison Table of Welding Machine Parameters

for the second level parameter setting interface.

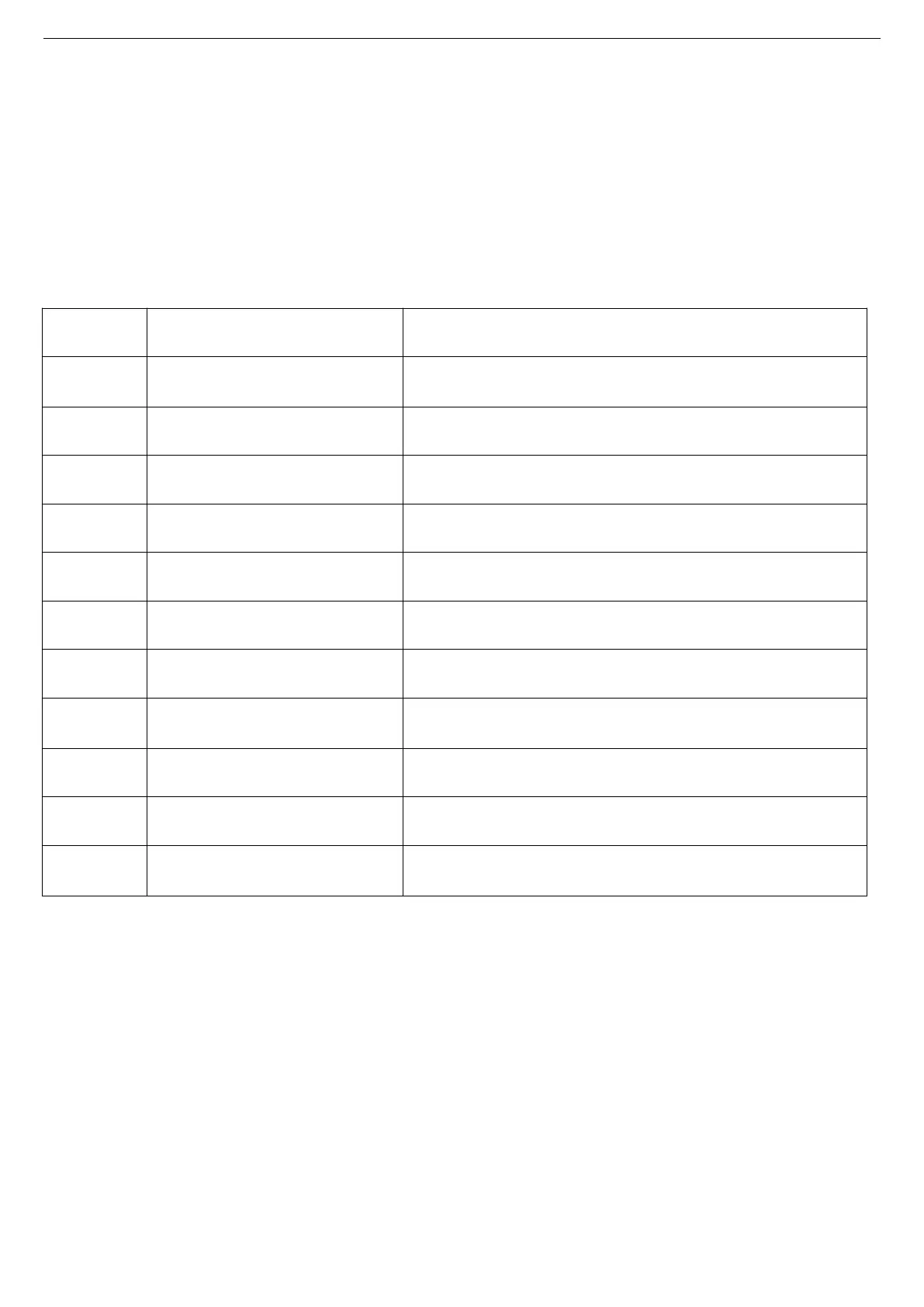

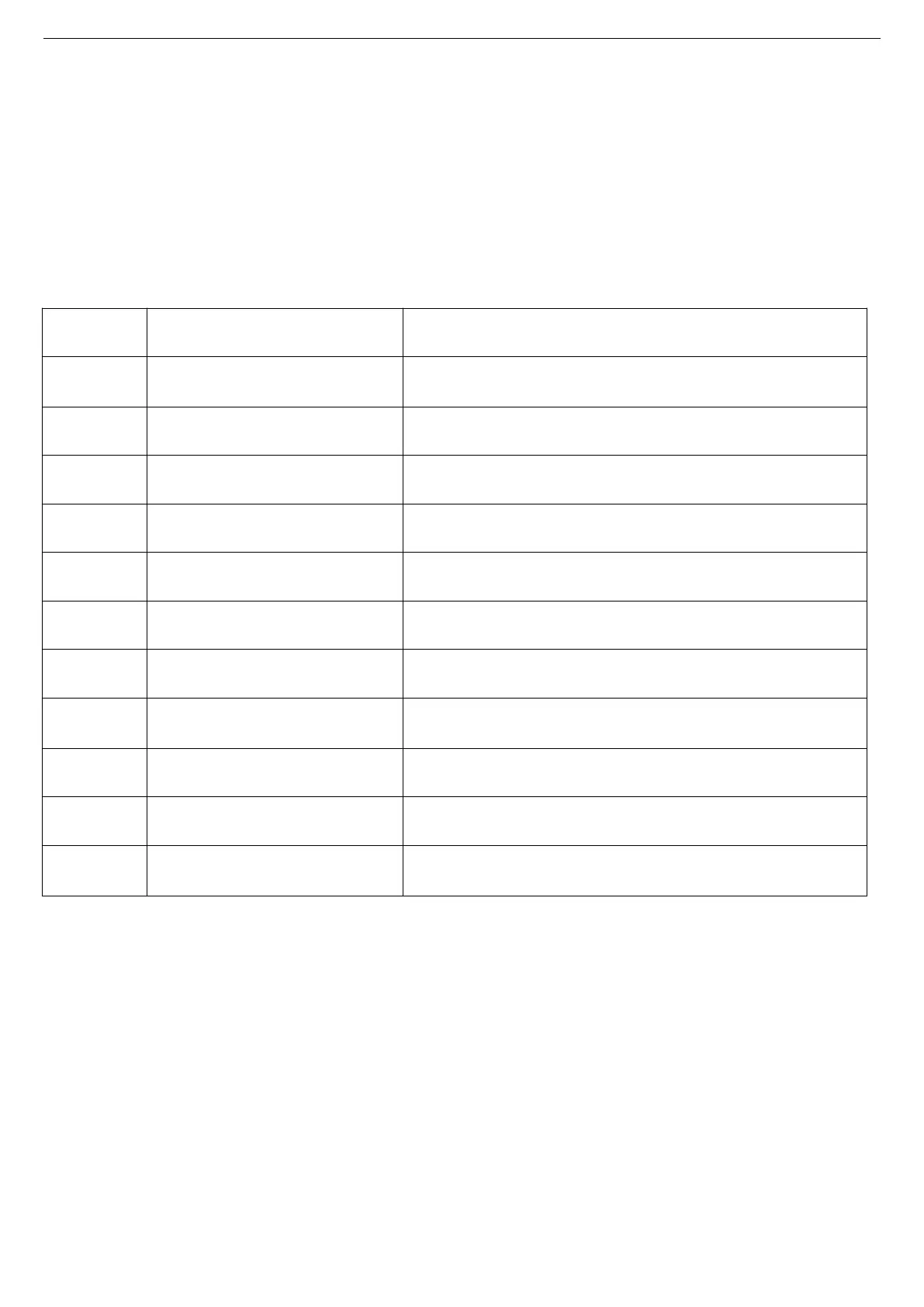

Table 5-2

For different welding methods, the inductance/arc

force has different functions.

Enter the second level parameter setting interface.

It is used for manual covered-electrode welding.

It is used for setting the gas preflow time.

Support 2T/4T operation mode.

It is used for setting the low wire feed rate.

It is used for setting the gas postpone time.

It is used for adjusting the ball cutting effect at the

end of welding.

It is used for restoring factory setting.

It is used for setting 4T current downslope time.

Four-step arc extinguishing

current

It is used for setting 4T arc extinguishing current.

Part 6: Machine operation guidance.

Tips:

1. Wear a welding helmet fitted with a proper shade of filter to protect your face and eyes when welding or watching;

2. Wear approved safety glasses. Side shields recommended;

3. Use protective screens or barriers to protect others from flash and glare; warn others not to watch the arc;

4. Wear protective clothing made from durable, flame-resistant material(wool and leather) and foot protection;

5. Use approved ear plugs or ear muffs if noise level is high;

6. Never wear contact lenses while welding.

Loading...

Loading...