Version Number: RBM2000P-20210517A1

15、Welding gun installation

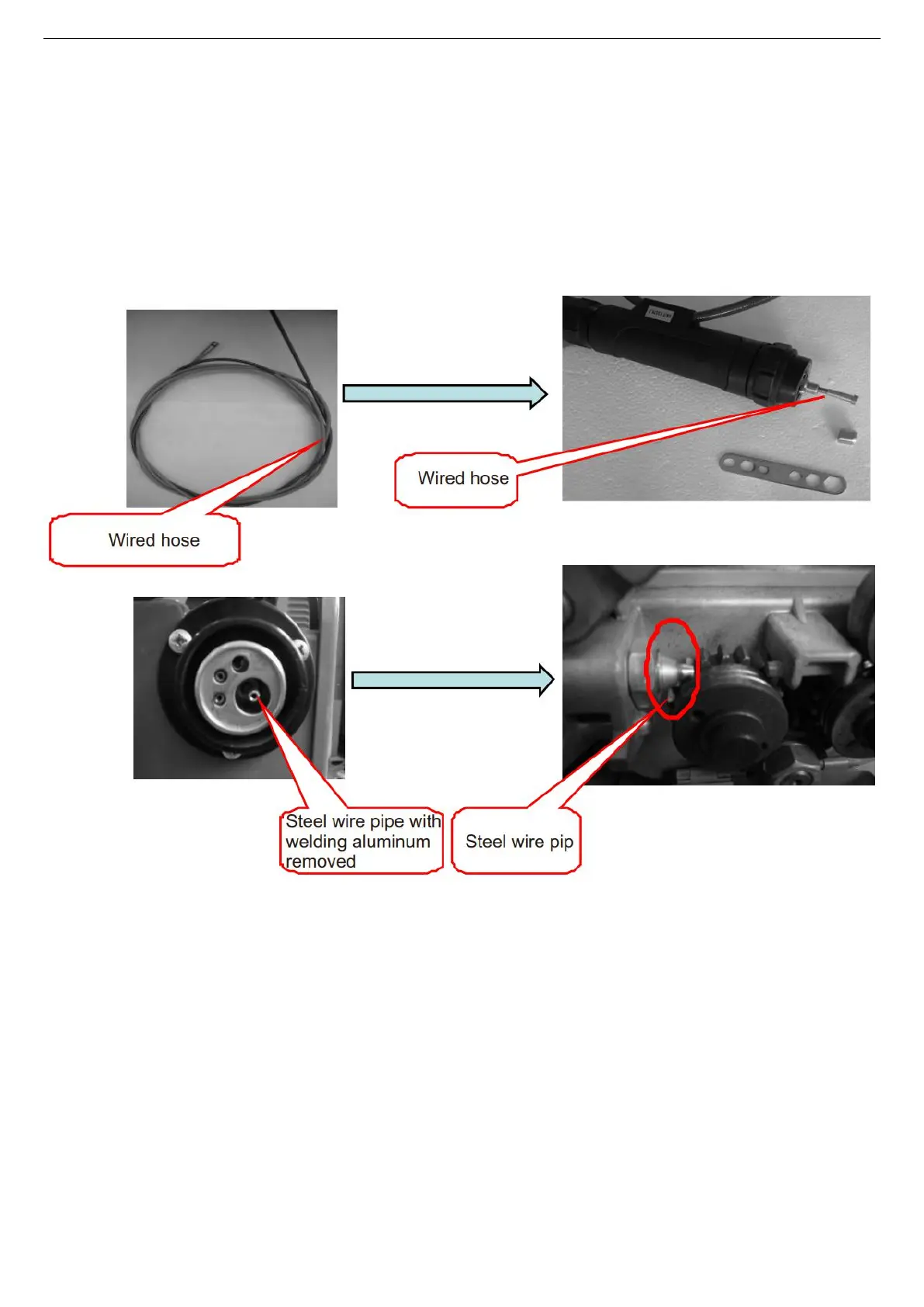

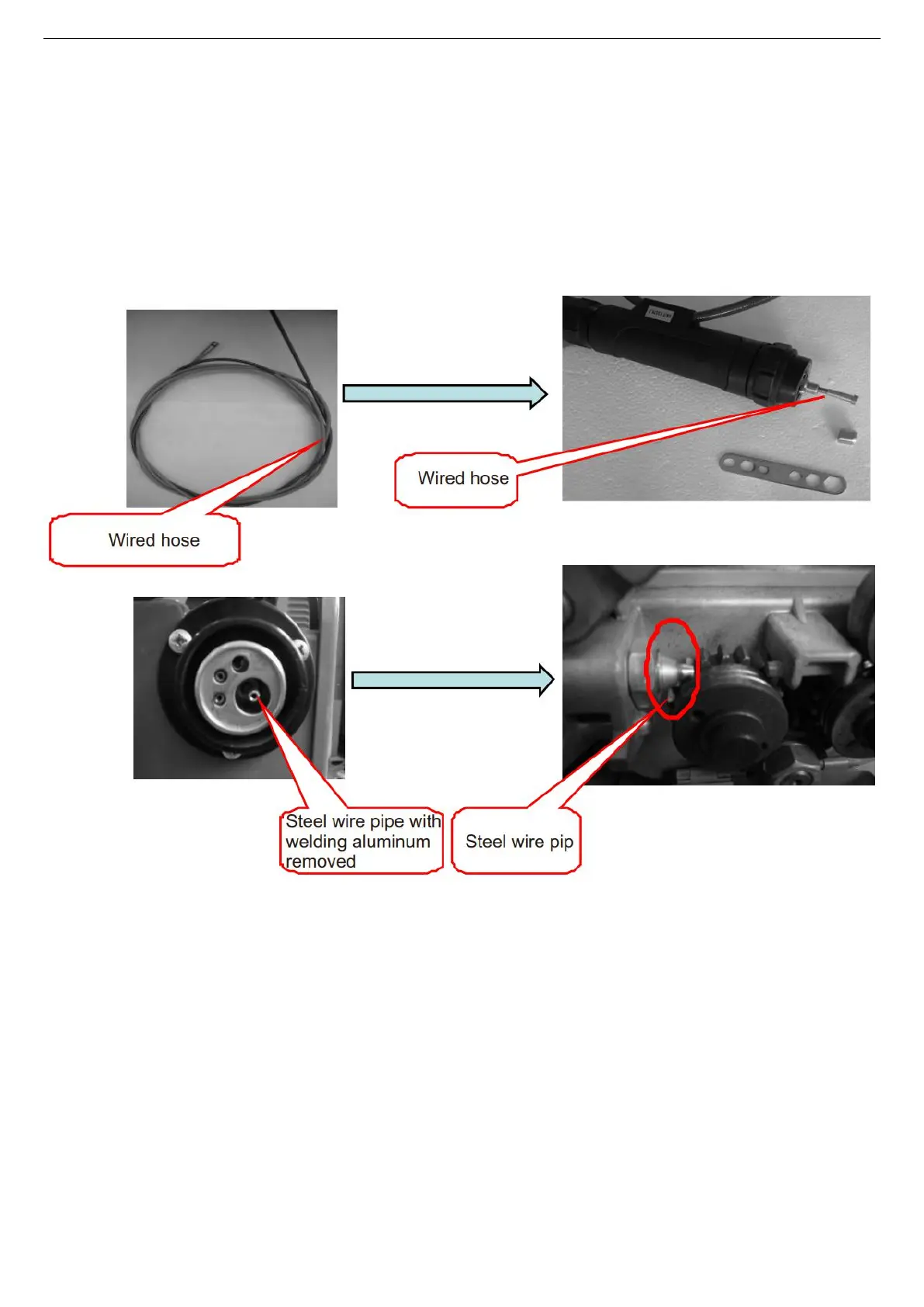

To ensure smooth welding, check that the wire feeding pipe and contact tip match the type of the welding

torch and that the wire feeding pipe matches the wire diameter and type. Wired hoses are suitable for hard

wires such as solid carbon steel wires and stainless steel wires, while Teflon hoses are suitable for soft

wires such as aluminum and its alloy wires, and copper and its alloy wires. If the wire feeding pipe is tight

or loose, the wire feeding resistance increases, which leads to unstable wire feeding. Tighten the quick joint

of the welding torch to prevent voltage drop on the contact surface. Loose contact causes pressure drop,

which causes the torch and wire feeder to be overheated.

Loading...

Loading...