Version Number: RBM2000P-20210517A1

10、Remove consumables and depress trigger until wire comes out. Replace consumables.

10、Adjust wire feed speed, current and voltage and so on.

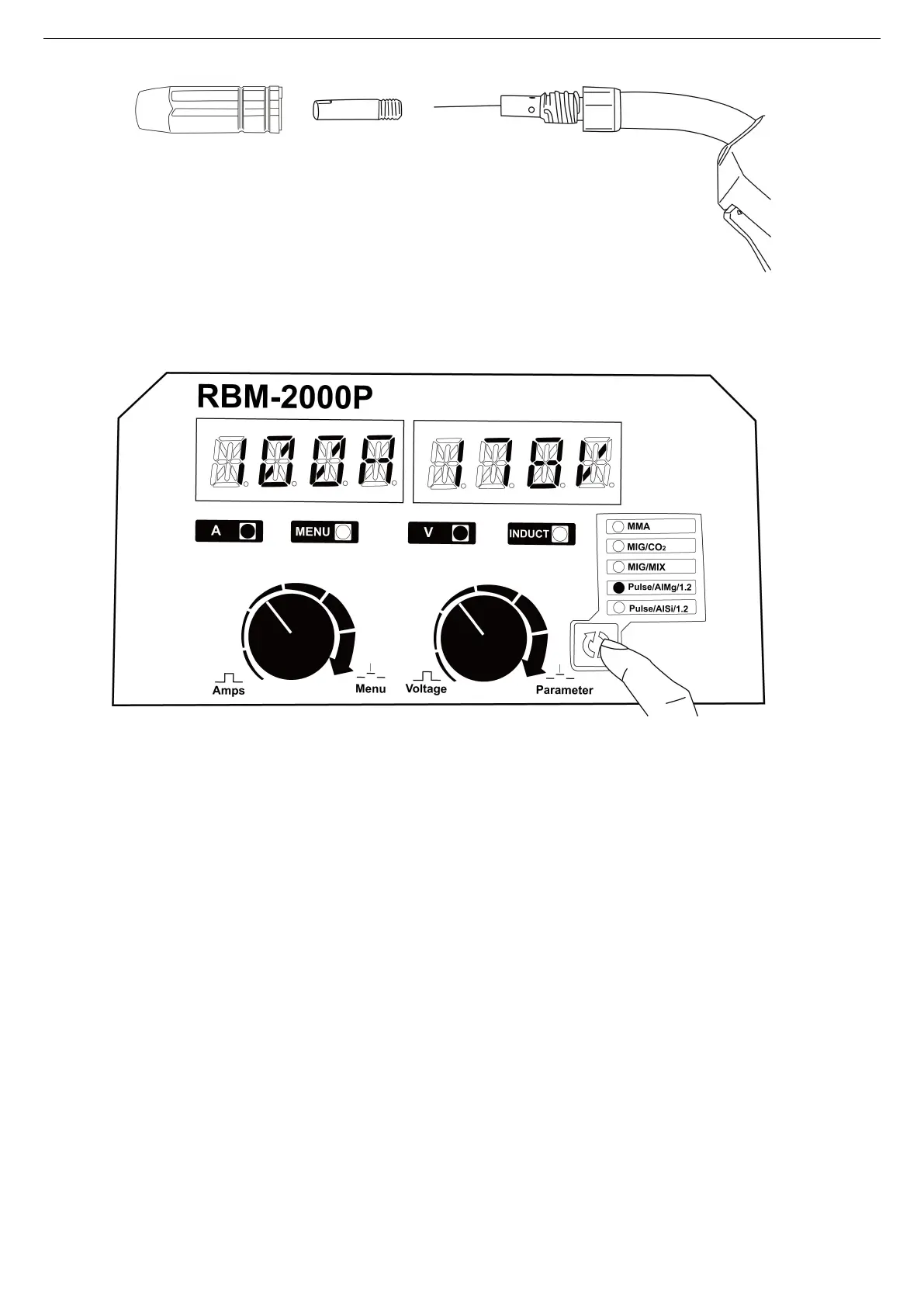

Adjustable parameters for gas shielded arc welding.

1. Current:

The welding machine uses the built-in intelligent system with the function of unification. The user can

select the corresponding current according to the thickness of the welded plate, and the wire feeding

speed is not required to be adjusted.

2. Arc length:

The expert database has given the standard arc length (=0), and the user can appropriately increase or

decrease the arc length on this basis according to the process requirements.

3. Inductance:

The standard inductance given by the expert database is 0, and the user can appropriately increase or

decrease the inductance/arc force on this basis according to the process.

For different welding methods, inductance has different functions:

MIG/MIX: < 0: get a harder and more stable arc, =0: medium arc, > 0: soft arc, small spatter.

Pulse MIG: < 0: reduce the droplet transfer force, =0: medium droplet transfer force, > 0: increase the

droplet transfer force.

4. Selection of operating mode:

The selection of operating mode located in the second level parameter setting menu. There are three

operating modes: 2T\4T.

17、With contact tip 1/4” from metal, depress trigger completely to initiate arc.

Loading...

Loading...