Version Number: RBM2000P-20210517A1

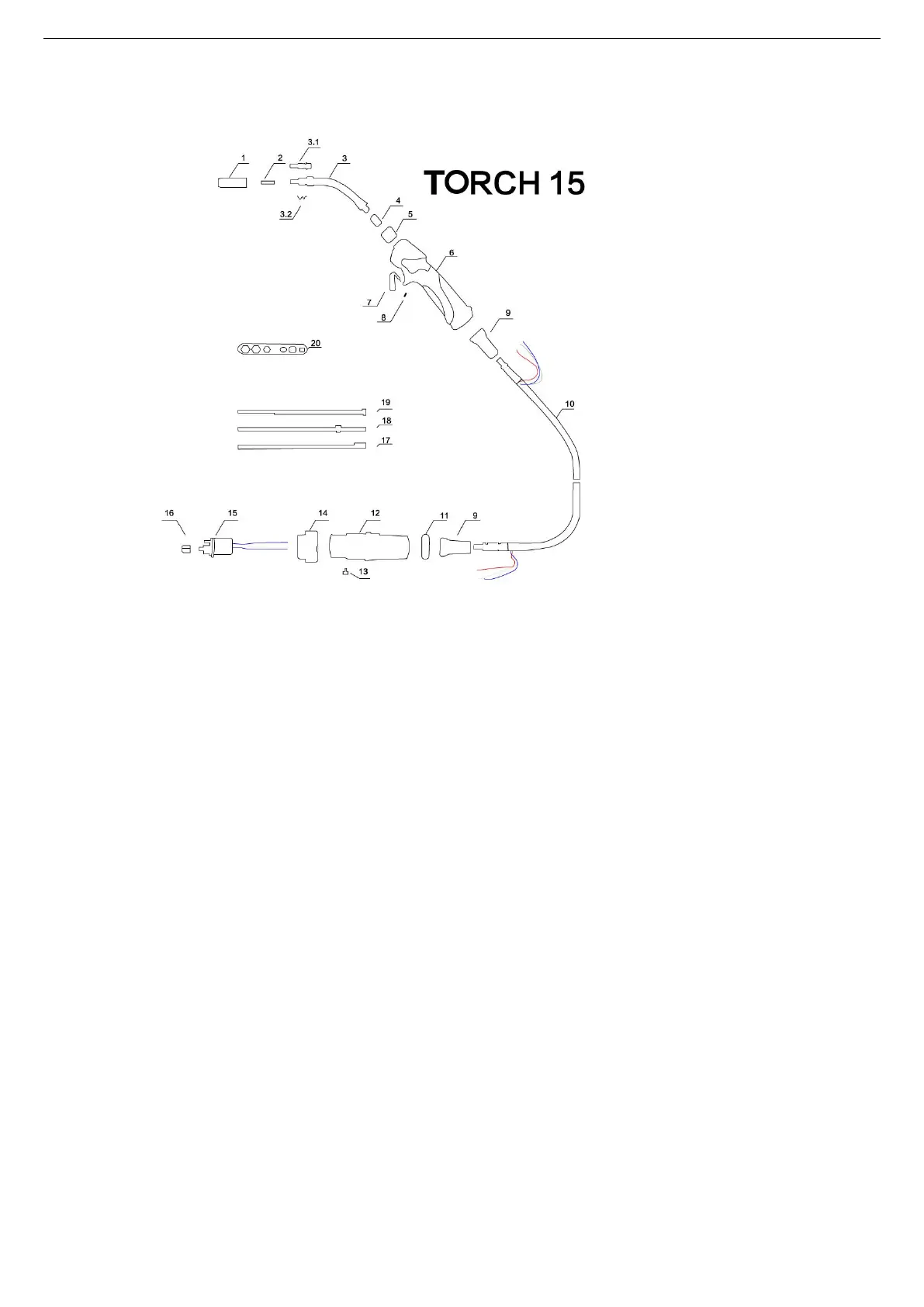

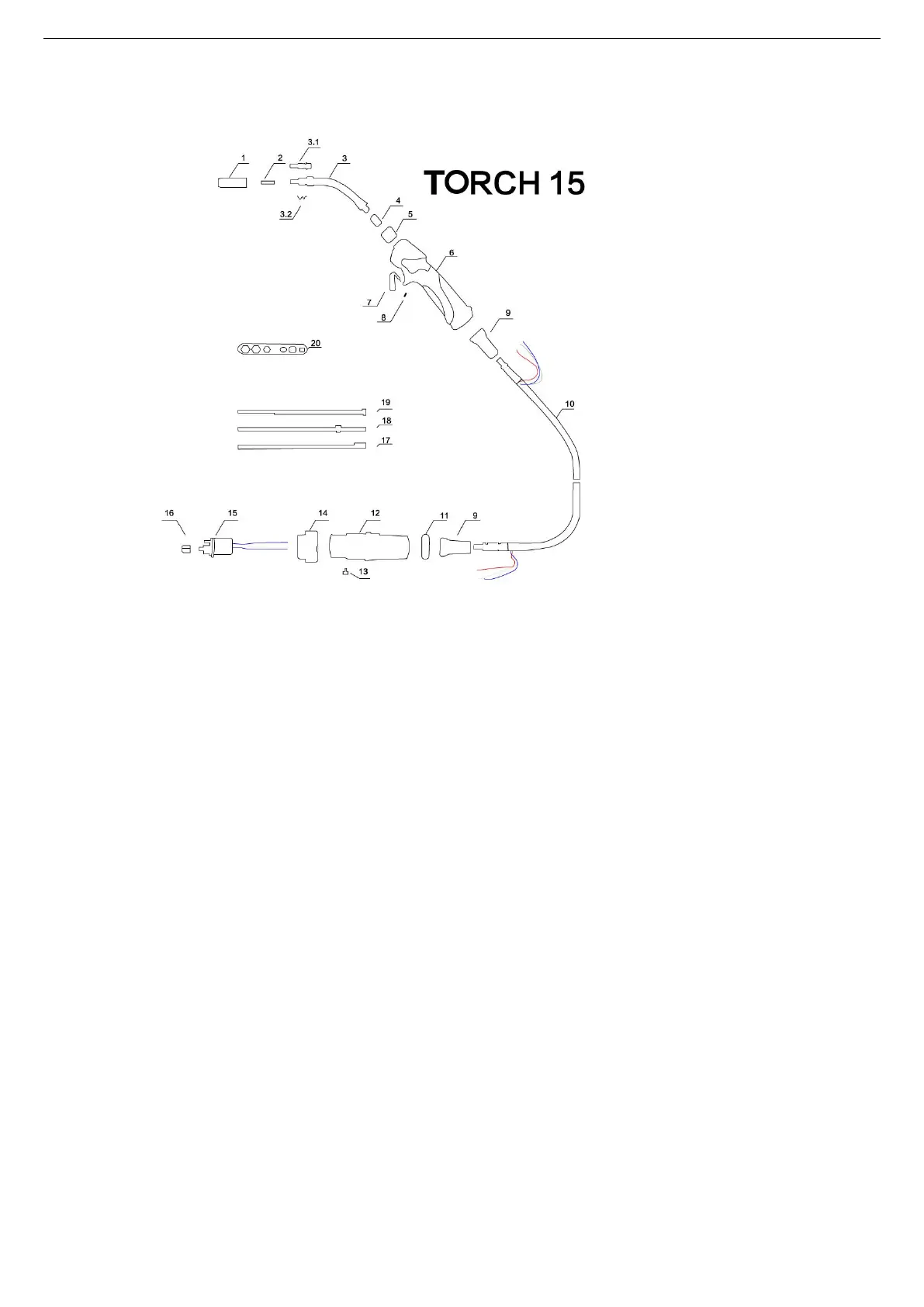

16、Structure of welding gun

Note: 1. Nozzle, 2. Conductive nozzle. They are wearing parts and need to be replaced frequently, please

keep inventory. 19. The guide wire tube, it is best to equip a spare part because it may damage the

accessories.

Note:

1) Please strictly follow the picture instructions to connect, otherwise it will not be possible to solder.

2) Solid core welding wire supports 0.8mm, 1.0mm, 0.6mm(need to purchase welding wire, wire feed wheel and

contact tip).

3) The machine can install 5kg(11lb) and 1kg(2.2lb) wire reels.

4) The machine comes with a 0.5kg(1.1lb) 5356AL-Mg welding wire or 1kg (2.2lb) Flux-cored wire.

5) Support welding material, carbon steel, stainless steel. And aluminum can not be welded in this mode.

6) The diameter of the welding wire, the groove of the wire feed wheel and the aperture of the contact tip must

match.

7) The pressure roller of the wire feeding structure should not be too tight or too loose, which will cause the wire

feeding to be unstable.

8) The installation of the wire feeding reel should not be too loose or too tight, which will cause the welding wire of

the wire reel to spring off and the wire feeding is too slow.

Possible problems

1) There is no response when turning on the power, please check the plug connection.

2) There is no response when turning on the power, please open the cover and check whether the internal

connecting wires are loose.

3) The wire feeding is unstable. Please check the wire feeding reel and the wire feeding pressure roller, and the

welding gun should not be wound. Pay attention that the diameter of the welding wire matches the wire feeding

Loading...

Loading...