Version Number: RBM2000P-20210517A1

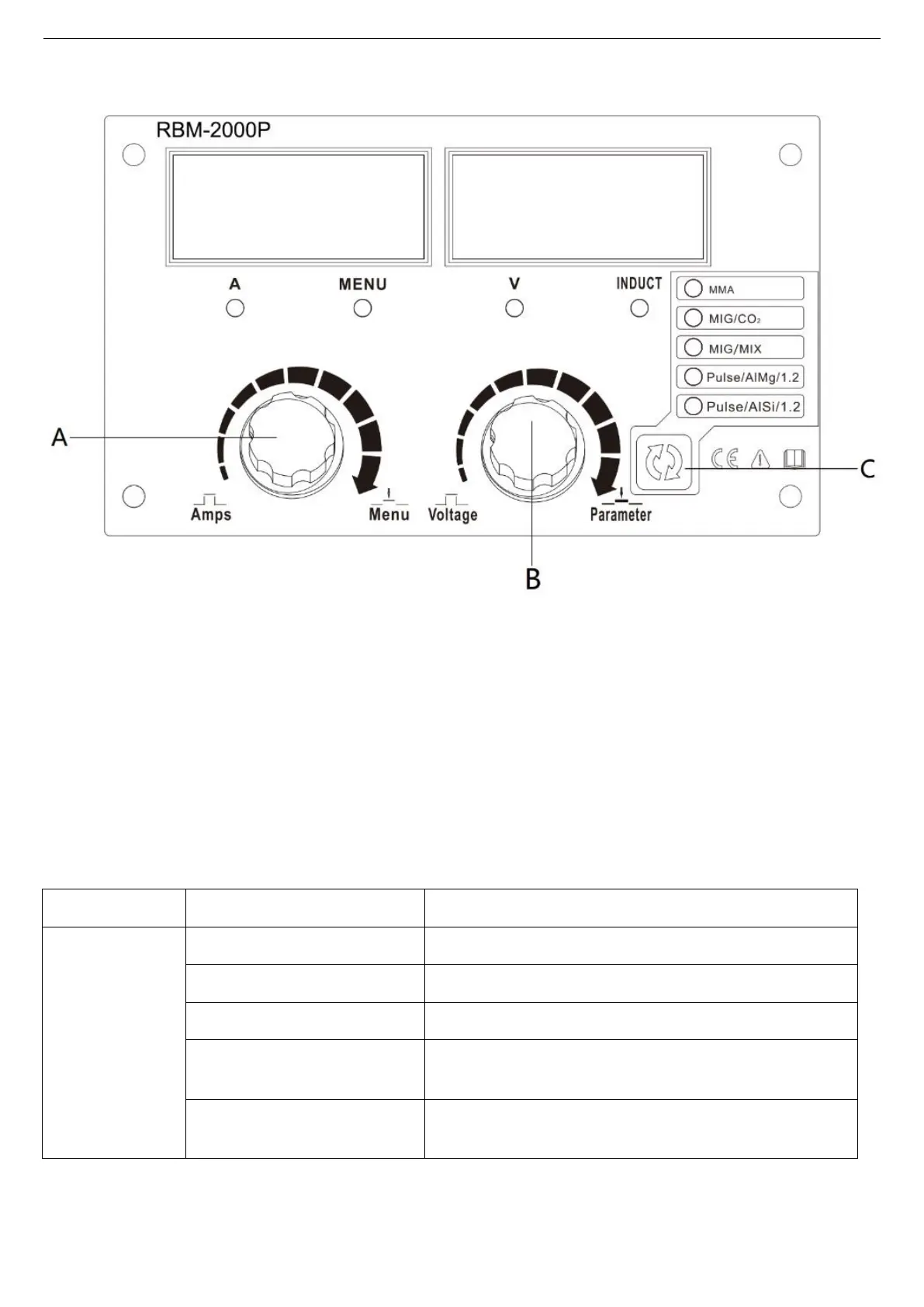

Part 5: Instructions of Operation Panel

The welding machine has two operating interfaces: first level panel setting interface and second level

parameter setting interface.

First level panel setting interface

After starting up, the welding machine will automatically enter the first level panel setting interface.

During welding, it will also automatically enter the first level panel setting interface.

(1) Current and voltage regulation

Knob A is used for regulating the current, and knob B is used for regulating the voltage/arc length.

(2) Selection of welding mode

Button C is used for selecting the welding mode. See Table 5-1 Comparison Table of Welding Modes

for specific welding modes.

Table 5-1

Manual covered-electrode welding.

Common gas shielded arc welding, carbon dioxide.

Common gas shielded arc welding, mixed gas.

Aluminum-magnesium pulse gas shielded arc welding, wire

diameter of 1.2.

Aluminium-silicon pulse gas shielded arc welding, wire

diameter of 1.2.

Remark: the unified default wire diameter of RBM2000P common gas shielded arc welding is 0.8mm. If

1.0mm wire is required, the parameters shall be matched manually .

(3) Regulation of arc force parameter

Press knob B, then the arc force indicator light (INDUCT) is on, and rotate knob B to adjust the arc length.

Loading...

Loading...