Version Number: RBM2000P-20210517A1

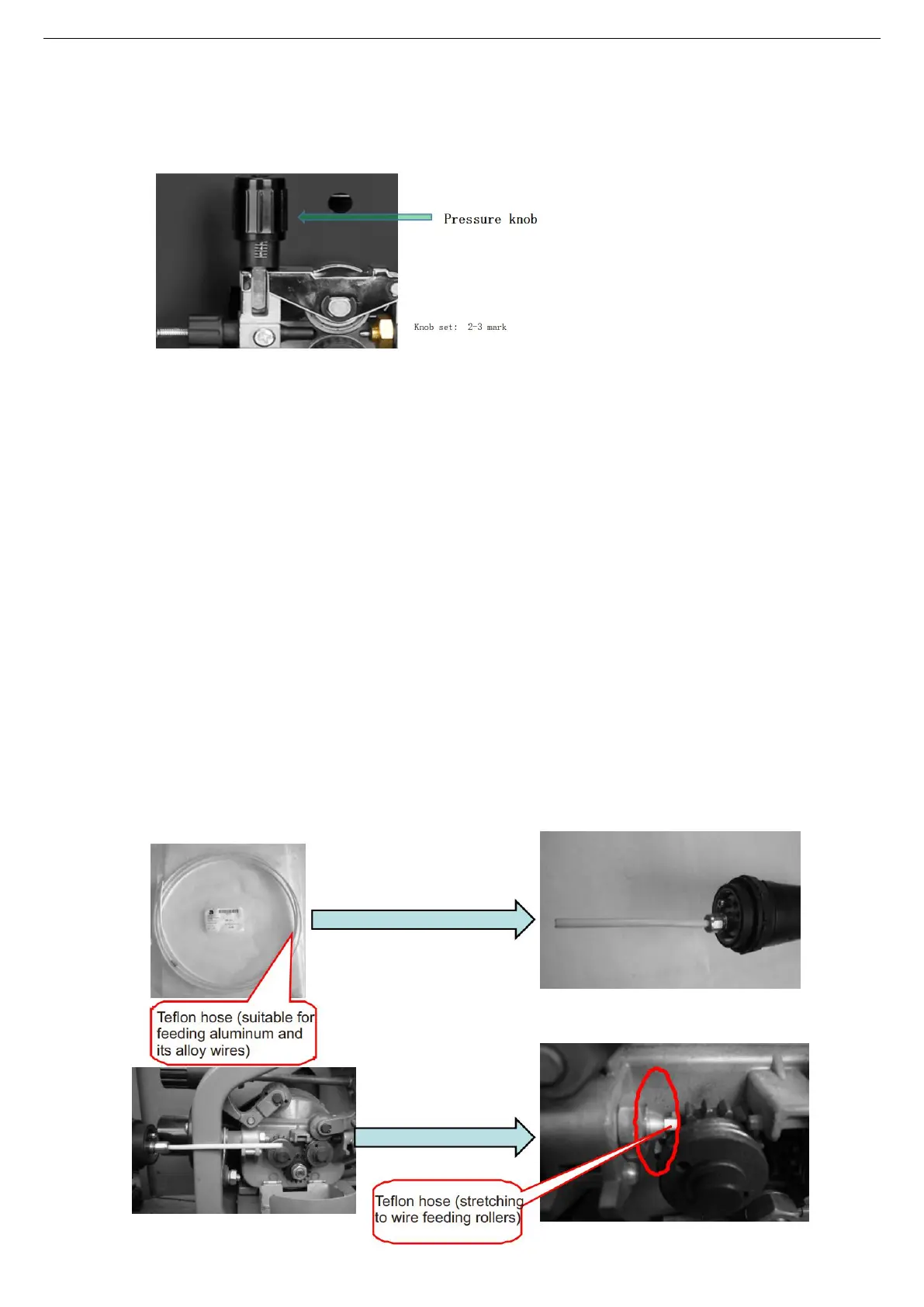

6、Feed wire and set pressure

The pressure should not be too loose, too loose will cause the welding wire to slip and the wire feeding is

unstable, and too tight will cause the welding wire to slip and deform.

7、Connect to Input Power

Please refer to the digital sign on the rear panel of the machine for the input voltage, the input voltage is AC

220V, the wrong voltage will damage the machine.

8、Please connect Argon gas.

1. Attach gas hose to machine.

2. Attach hose and regulator to gas bottle.

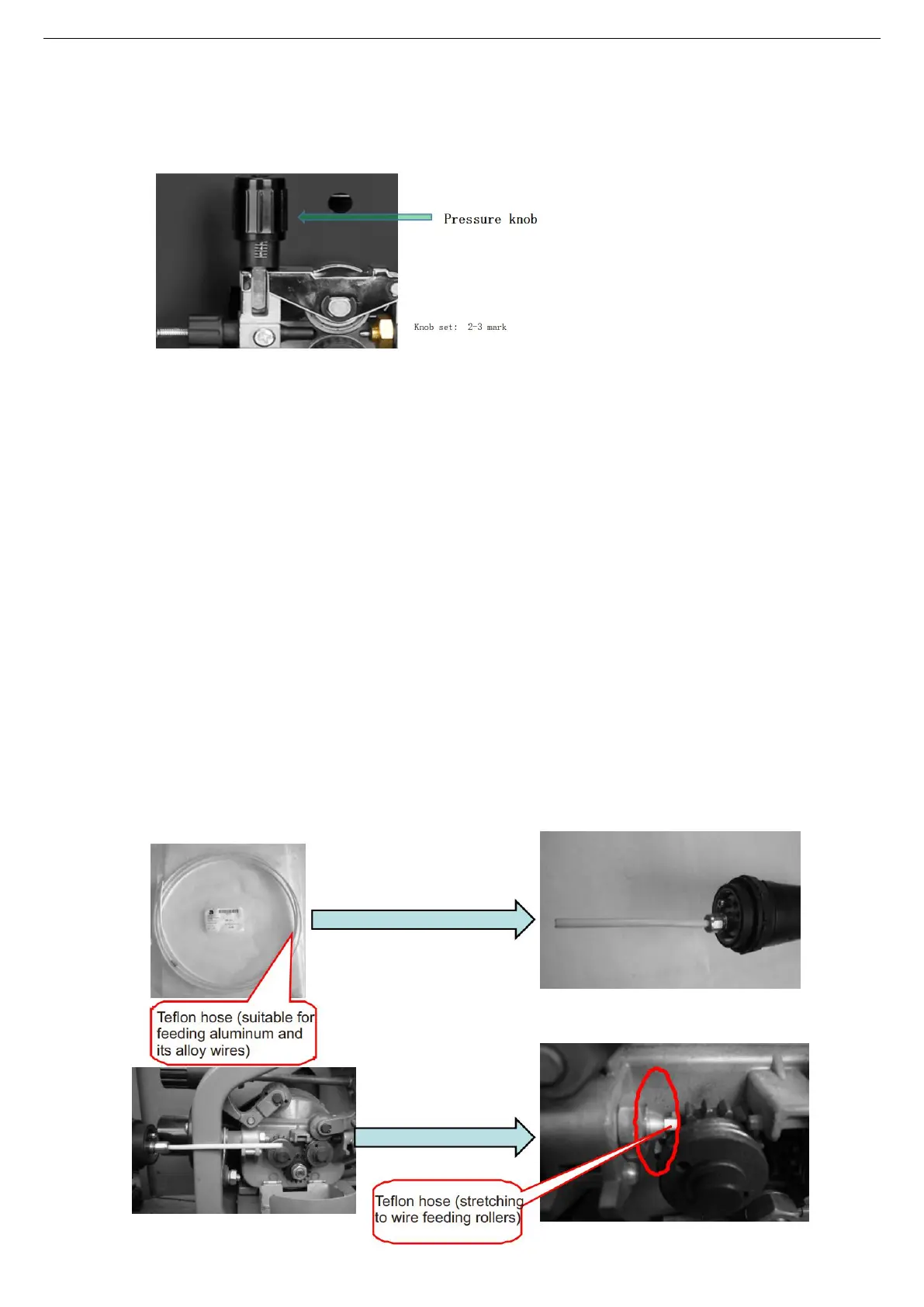

9、Installation of welding torch.

To ensure smooth welding, check that the wire feeding pipe and contact tip match the type of the welding

torch and that the wire feeding pipe matches the wire diameter and type. While Teflon hoses are suitable for

soft wires such as aluminum and its alloy wires, and copper and its alloy wires. If the wire feeding pipe is tight

or loose, the wire feeding resistance increases, which leads to unstable wire feeding. Tighten the quick joint

of the welding torch to prevent voltage drop on the contact surface. Loose contact causes pressure drop,

which causes the torch and wire feeder to be overheated. Long press the A knob, This is fast wire feeding, Let

the welding wire be quickly delivered to the gun head. Please make sure that the welding torch is not bent, so

that the welding wire will be blocked.

Loading...

Loading...