Section 3

INSTALLATION

3.0 General - This Section outlines the procedures that

are to be followed in order to properly install a FlexPak Plus

controller .

The d-c motor should be installed and wired in accordance

with installation instructions supplied with each drive.

There are certain general warnings and cautions that

should be kept in mind

before planning begins. They

should be considered a general checklist which, if followed,

will minimize installation problems and decrease assembly

time . As a user aid, they are listed here .

DANGER

THIS UNIT SHOULD BE INSTALLED, ADJUSTED

AND SERVICED BY QUALIFIED ELECTRICAL

MAINTENANCE PERSONNEL FAMILIAR WITH

THE CONSTRUCTION AND OPERATION OF THIS

TYPE.OF EQUIPMENT . THEY SHOULD ALSO BE

{' FAMILIAR ' WITH THE POTENTIAL HAZARDS IN-

VOLVED. IF THIS WARNING IS NOT OBSERVED,

PERSONAL INJURY OR EQUIPMENT DAMAGE

MAY RESULT.

DANGER

BE ABSOLUTELY CERTAIN THAT A GROUND

WIRE FROM THE INCOMING A-C POWER LINE IS

PROPERLY CONNECTED TO THE CHASSIS

GROUND TERMINAL PROVIDED . WITHOUT

PROPER GROUNDING, PERSONAL INJURY MAY

OCCUR.

WARNING

THE CONTROLLER REQUIRES A SINGLE-PHASE

POWER SUPPLY THAT PROVIDES EITHER 115

VAC OR

230 VAC AT 50 / 60 HZ. IF CORRECT

VOLTAGE IS NOT AVAILABLE, IT WILL BE

NECESSARY TO INSTALL A TRANSFORMER

BETWEEN THE POWER SUPPLY AND THE CON-

TROLLER . DO NOT OPERATE THE FLEXPAK PLUS

CONTROLLER ON POWER SUPPLIES WITH

AVAILABLE SHORT -CIRCUIT CURRENTS IN

EXCESS OF

5000 AMPERES . DAMAGE TO

EQUIPMENT AND PERSONAL INJURY MAY

OCCUR .

WARNING

THE USER IS RESPONSIBLE FOR CONFORMING

WITH THE NATIONAL ELECTRICAL CODE WITH

RESPECT TO MOTOR. CONTROLLER AND OPER-

ATOR DEVICE INSTALLATION, WIRING AND

START-UP. THE USER IS ALSO RESPONSIBLE

FOR UNDERSTANDING AND APPLYING ALL

OTHER APPLICABLE LOCAL CODES WHICH

GOVERN SUCH PRACTICES AS WIRING PRO-

TECTION, GROUNDING, DISCONNECTS AND

OVERCURRENT PROTECTION.

9

3.1 Layout Guidelines - This Paragraph lists recom-

mended layout procedures common to all FlexPak Plus

controllers .

Guideline 1 -The FlexPak Plus controller is designed as a

panel-mounted unit. It is to be hung within 10° of vertical

with the rear of the Chassis firmly resting against the

mounting surface.

(Do not position the Chassis on a hori-

zontal surface .)

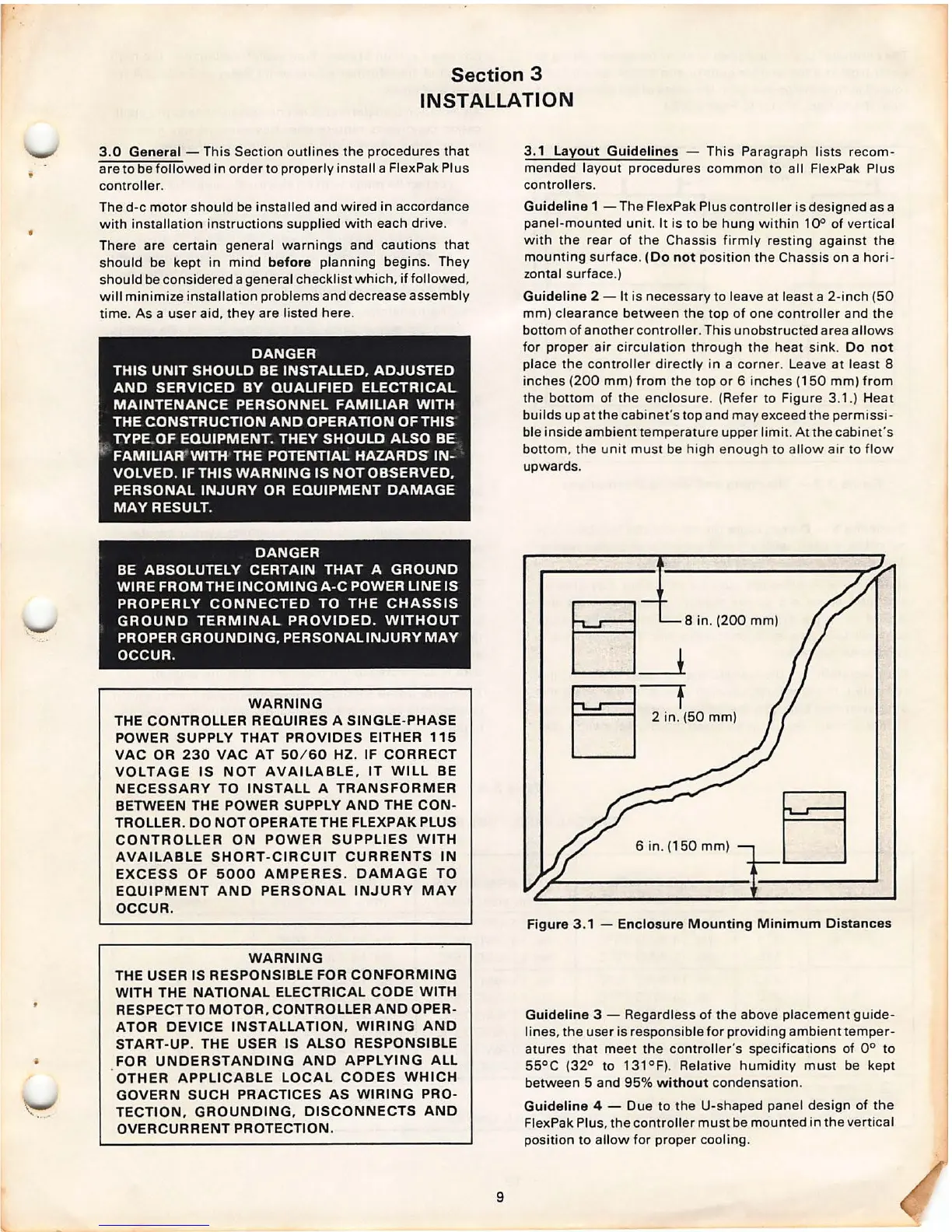

Guideline 2 - It is necessary to leave at least a 2-inch (50

mm) clearance between the top of one controller and the

bottom of another controller . This unobstructed area allows

for proper air circulation through the heat sink .

Do not

place the controller directly in a corner . Leave at least 8

inches (200 mm) from the top or 6 inches (150 mm) from

the bottom of the enclosure . (Refer to Figure 3.1.) Heat

builds up at the cabinet's top and may exceed the permissi-

ble inside ambient temperature upper limit . At the cabinet 's

bottom , the unit mus t be high enough to allow air to flow

upwards .

E:] __ ; ;n. (200 mm(

EJ--:}(50 mm}

6 in . (150 mm)

Figure 3 .1 - Enclosure Mounting Minimum Distances

Guideline 3 -

Regardless of the above placement guide-

lines , the user is responsible for providing ambient temper-

atures that meet the

controller's specifications of 0° to

55°C (32° to 131°F). Relative humid ity must be kept

between 5 and 95%

without condensation .

Guideline 4 - Due to the U-shaped panel design of the

FlexPak Plus, the controller must be mounted in the vertical

position to allow for proper cooling .

Loading...

Loading...