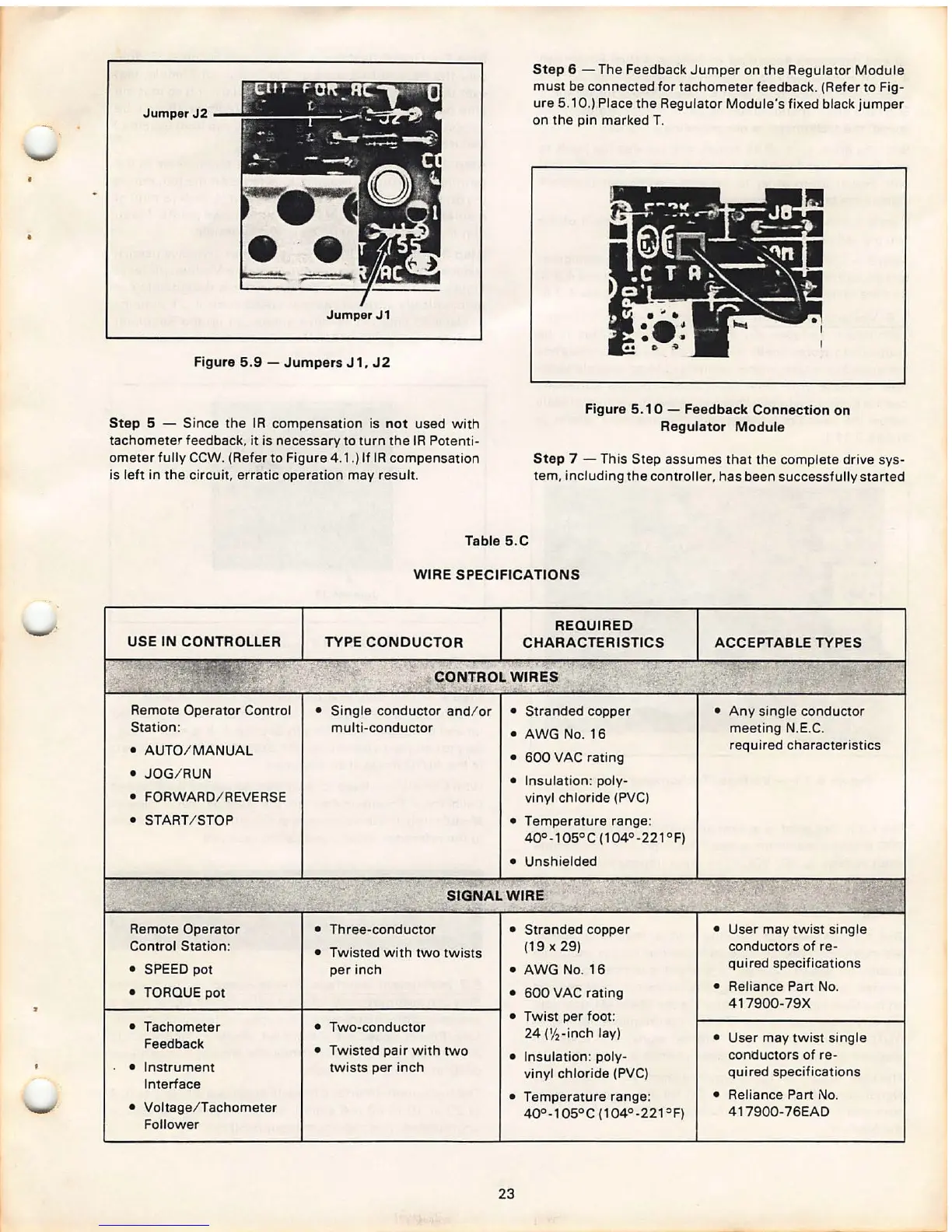

JumperJ2

Jumper J1

Figure 5.9 - Jumpers J 1. J2

Step

5 - Since the IR compensation is not used with

tachometer feedback , it is necessary to turn the IR Potent i-

ometer fully CCW. (Refer to Figure 4.1.) If IR compensation

is left in the circuit. erratic operation may result .

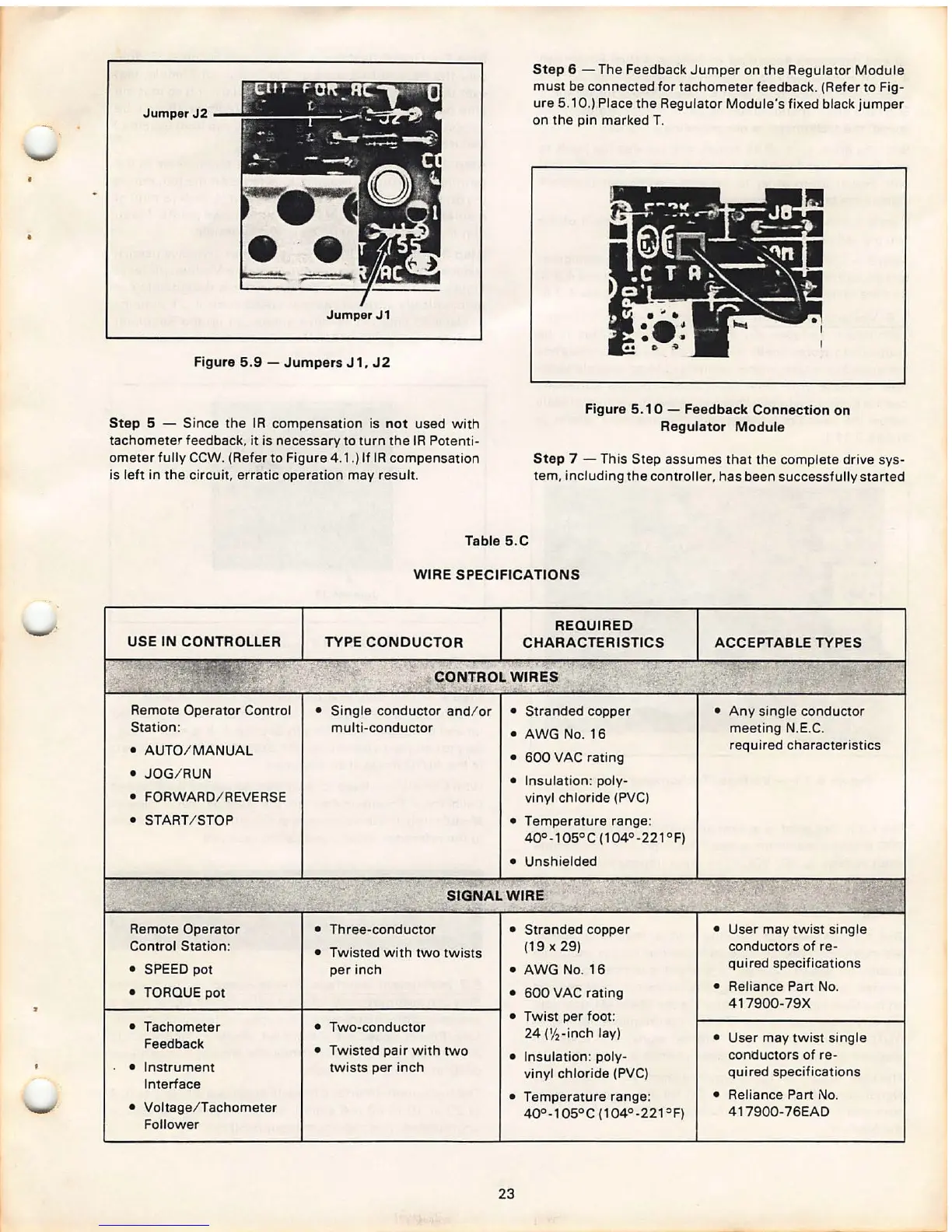

Step 6 - The Feedback Jumper on the Regulator Module

must be connected for tachometer feedback . (Refer to Fig-

ure 5.10 .) Place the Regulator Module 's fixed black jumper

on the pin marked T.

Figure 5. 1 0 - Feedback Connection on

Regulator Module

Step

7 - This Step assumes that the complete drive sys-

tem, including the controller , has been successfully started

Table 5.C

USE IN CONTROLLER

Remote Operator Control

Station :

• AUTO / MANUAL

• JOG / RUN

• FORWARD / REVERSE

• START / STOP

Remote Operator

Control Station :

• SPEED pot

• TORQUE pot

• Tachometer

Feedback

• Instrument

Interface

• Voltage / Tachometer

Follower

WIRE SPECIFICATIONS

TYPE CONDUCTOR

REQUIRED

CHARACTERISTICS

CONTROL WIRES

• Single conductor and/ or

multi -conductor

• Stranded copper

• AWG No. 16

• 600 VAC rating

• Insulation : poly-

vinyl chloride (PVC)

• Temperature range :

40° -105 ° C (104°- 221°F)

• Unshielded

SIGNAL WIRE

• Three -conductor • Stranded copper

• Twisted with two twis ts

(19

X 29)

per inch

• AWG No. 16

• 600 VAC rating

• Two -conductor

• Twist per foot :

24

(1/

2

-inch lay)

• Twisted pair with two

• Insulation : poly-

twists per inch

vinyl chloride (PVC)

• Temperature range :

40° -105° C (104 °- 221

Of)

23

ACCEPTABLE TYPES

• Any single conductor

meeting N.E.C.

required characteristics

• User may twist single

conductors of re-

qui red specifications

• Relianc e Part No.

417900 -79X

• User may twist single

conductors of re-

quired specifications

• Reliance Part

No.

417900- 76EAD

Loading...

Loading...