The Kit is designed to accept a line speed input signal of 4 to

10 VDC to obtain maximum speed. The input impedance

between the line speed input terminals 57 and 726 is

approximately 25,000 ohms. The Dancer Potentiometer

will provide up to a 20% trim to the line speed signal.

The user must supply the required lengths of the specified

signal wire. (Refer to Table 5.C.) A Dancer Potentiometer

and an optional Dancer Position Potentiometer are also to

be supplied by the user .

To install the Kit follow these procedures .

Step 1 - Refer to Figure 6.4 and note the heavy border

area in the center of the Regulator Module marked REFER-

ENCE. This is the area where the Dancer Follower Module

is to be mounted. Place the Dancer Follower Module in the

proper orientation so the pin guides on the Module are

aligned over the set of five pins on the Regulator Module.

Lower the Dancer Follower Module so the pins pass

through the pin guides and the mounting spacer seats in

the mounting hole. (It may be necessary to remove a protec -

tive plastic cap from the pins .) Secure the Module with the

supplied screw.

Step 2 - Connect the black pig-tail jumper of the Dancer

Follower Module to pin 319 on the Regulator Module. (Pin

319 is the third pin down in the group of pins marked

TORQUE TAPER.)

Step 3 - Using a twisted pair, connect the external line

speed input to the terminal strip of the Dancer Follower

Module. The plus (+)wire is connected to terminal 726and

the minus (-) wire is connected to terminal 57.

NOTE : Do not strip more than 1/

8

inch (3 mm) of insulation

off the ends of the wires because a short circuit could occur

at any point where the bare wire is exposed. Maintain the

twisted configuration of the two wires as Jong as possible.

Step 4 - Using three twisted wires. connect the user

supplied 5K ohm Dancer Potentiometer to the terminal

strip of the Dancer Follower Module. The speed increase

side of the potentiometer connects to terminal 556 and the

speed decrease side connects to terminal 571. The potenti-

ometer wiper is connected to terminal 919.

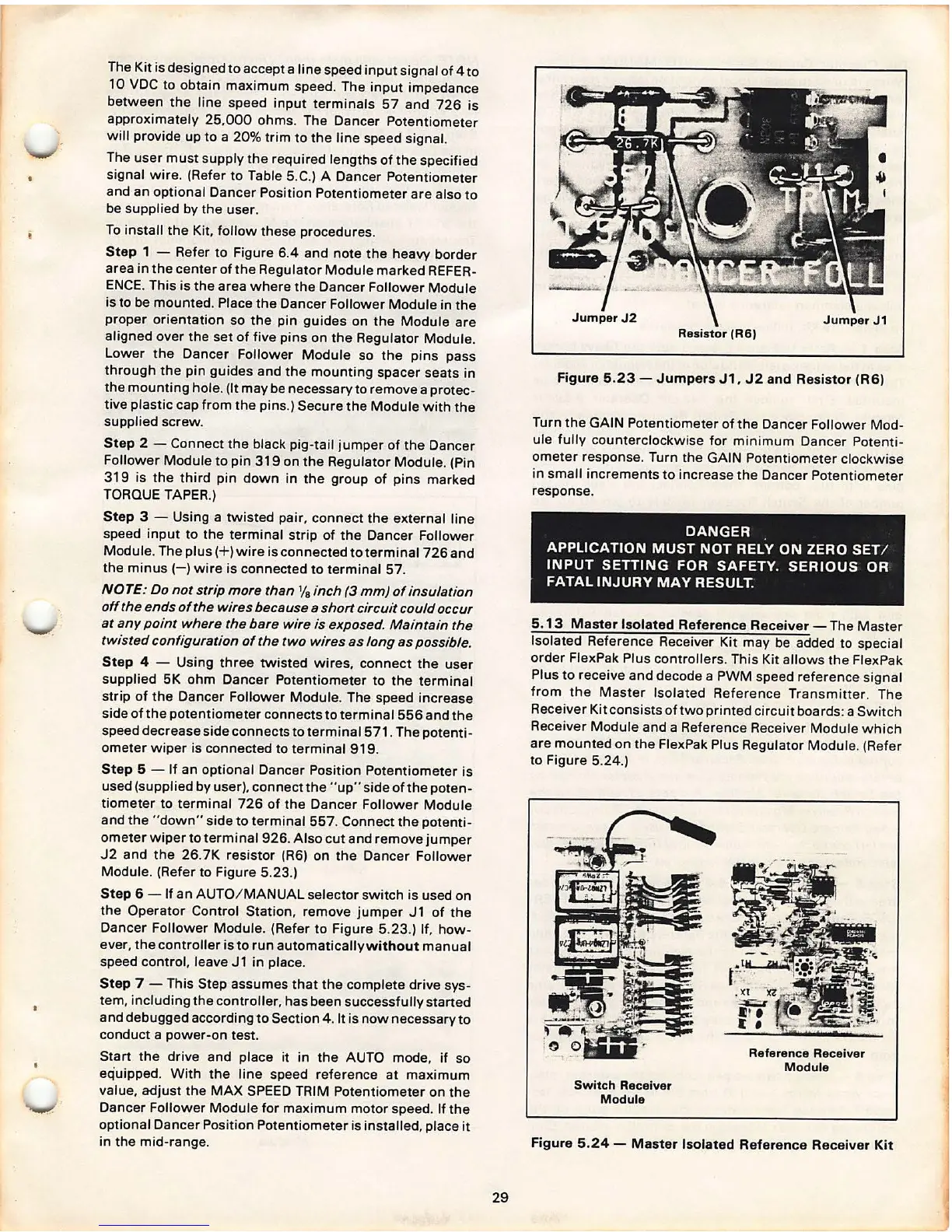

Step 5 - If an optional Dancer Position Potentiometer is

used (supplied by user), connectthe

"up " side of the poten-

tiometer to terminal 726 of the Dancer Follower Module

and the

"down" side to terminal 557 . Connect the potenti-

ometer wiper to terminal 926. Also cut and remove jumper

J2 and the 26.7K resistor (R6) on the Dancer Follower

Module . (Refer to Figure 5.23.)

Step 6 - If an AUTO / MANUAL selector switch is used on

the Operator Control Station, remove jumper J1 of the

Dancer Follower Module. (Refer to Figure 5.23 .) If, how-

ever, the controller is to run automaticallywithout manual

speed control, leave J1 in place .

Step 7 - This Step assumes that the complete drive sys-

tem, including the controller , has been successfully started

and debugged according to Section

4. It is now necessary to

conduct a power-on test.

Start the drive and place it in the AUTO mode, if so

equipped. With the line speed reference at maximum

value , adjust the MAX SPEED TRIM Potentiometer on the

Dancer Follower Module for maximum motor speed. If the

optional Dancer Position Potentiometer is installed, place it

in the mid-range.

29

Resistor (R6)

Figure 5.23 - Jumpers J1. J2 and Resistor (R6)

Turn the GAIN Potentiometer of the Dancer Follower Mod-

ule fully counterclockwise for minimum Dancer Potent i-

ometer response . Turn the GAIN Potentiometer clockwise

in small increments to increase the Dancer Potentiometer

response .

DANGER

APPLICATION MUST NOT

RELY ON ZERO SET/

INPUT SETTING FOR SAFETY. SERIOUS OR

FATAL INJURY MAY RESULT.

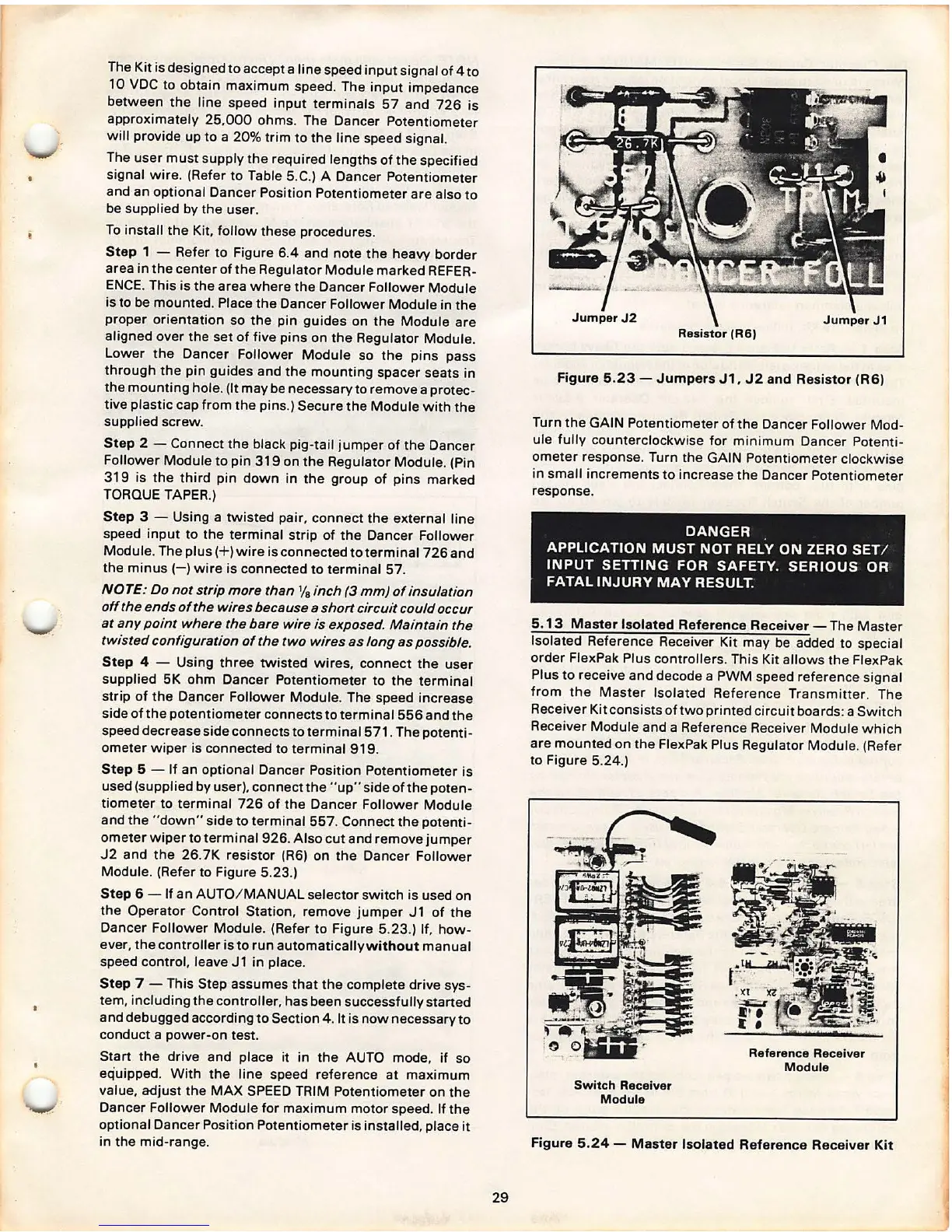

5. 13 Master Isolated Reference Receiver -

The Master

Isolated Reference Receiver Kit may be added to special

order FlexPak Plus controllers. This Kit allows the FlexPak

Plus to receive and decode a PWM speed reference signal

from the Master Isolat ed Reference Transmitter . The

Receiver Kit consists of two printed circuit boards: a Switch

Receiver Module and a Reference Receiver Mod ule which

are mounted on the FlexPak Plus Regulator Modul e. (Refer

to Figure 5.24.)

Sw itch Receiver

Module

Reference Receiver

Module

Figure 5.24 - Master Isolated Reference Receiver Kit

Loading...

Loading...