up and debugged according to Section 4 thru Paragraph

4.3.1 . It is necessary to carry out a power-on test . Set the

SPEED Potentiometer at approximately 25%of full rotation .

Start the drive . It should run as set. If it accelerates to full

speed, the tachometer is not providing a signal.

Stop the drive, turn off all power , and reverse the leads to

the Tachometer Module 's terminal strip . Repeat the test

with power on in order to confirm that proper feedback

signals are being received by the regulator .

If erratic behavior continues, check the placement of the

two pig-tail jumpers against Steps 3 and 5.

Step 8 - The Maximum and M inimum Speed Potentiome-

ters should now be adjusted to Paragraphs 4 .3.2 and 4.3.3.

Be sure to follow 4.3.4 and 4.3.5 but

do not follow 4 .3.6.

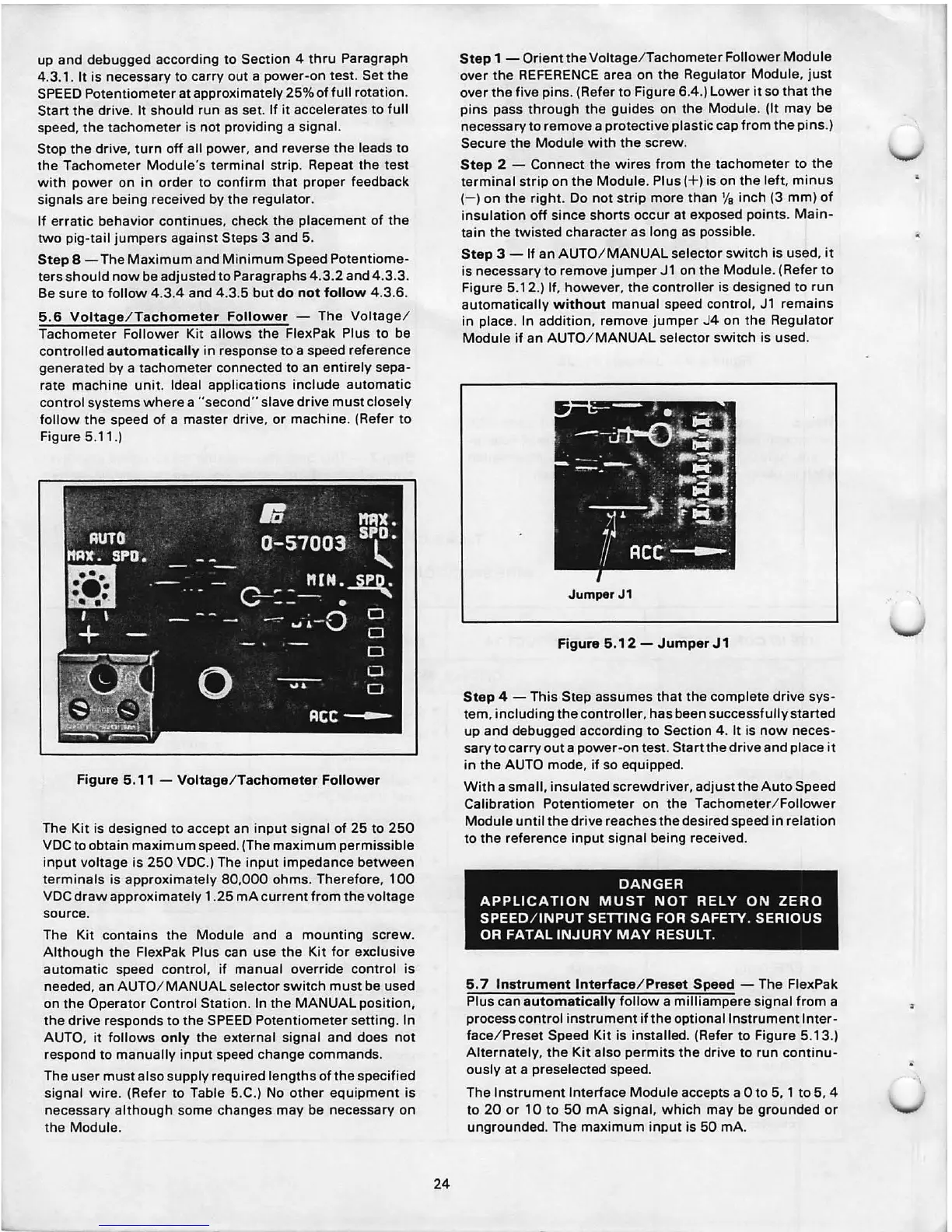

5.6

Voltage / Tachometer Follower - The Voltage /

Tachometer Follower Kit allows the FlexPak Plus to be

controlled

automatically in response to a speed reference

generated by a tachometer connected to an entirely sepa-

rate machine unit . Ideal applications include automatic

control systems where a "second" slave drive must closely

follow the speed of a master drive, or machine . (Refer to

Figure 5.11.)

Figure 5.11 - Voltage/Tachometer Follower

The Kit is designed to accept an input signal of 25 to 250

VDC to obtain maximum speed. (The maximum permissible

input voltage is 250 VDC.) The input impedance between

terminals is approximately 80,000 ohms . Therefore , 100

VDC draw approximately 1 .25 mA current from the voltage

source .

The Kit contains the Module and a mounting screw .

Although the FlexPak Plus can use the Kit for exclusive

automatic speed control, if manual override control is

needed , an AUTO/ MANUAL selector switch must be used

on the Operator Control Station. In the MANUAL position,

the drive responds to the SPEED Potentiometer setting. In

AUTO, it follows

only the external signal and does not

respond to manually input speed change commands .

The user must also supply required lengths of the specified

signal wire . (Refer to Table 5.C.) No other equipment is

necessary although some changes may be necessary on

the Module .

24

Step 1 - Orient the Voltage / Tachometer Follower Module

over the REFERENCE area on the Regulator Module, just

over the five pins . (Refer to Figure 6.4 .) Lower it so that the

pins pass through the guides on the Module. (It may be

necessary to remove a protective plastic cap from the pins .)

Secure the Module with the screw .

Step 2 - Connect the wires from the tachometer to the

terminal strip on the Modu le. Plus( + ) is on the left , minus

(-) on the right . Do not strip more than

1/

8

inch (3 mm) of

insulation off since shorts occur at exposed points. Main-

tain the twisted character as long as possible .

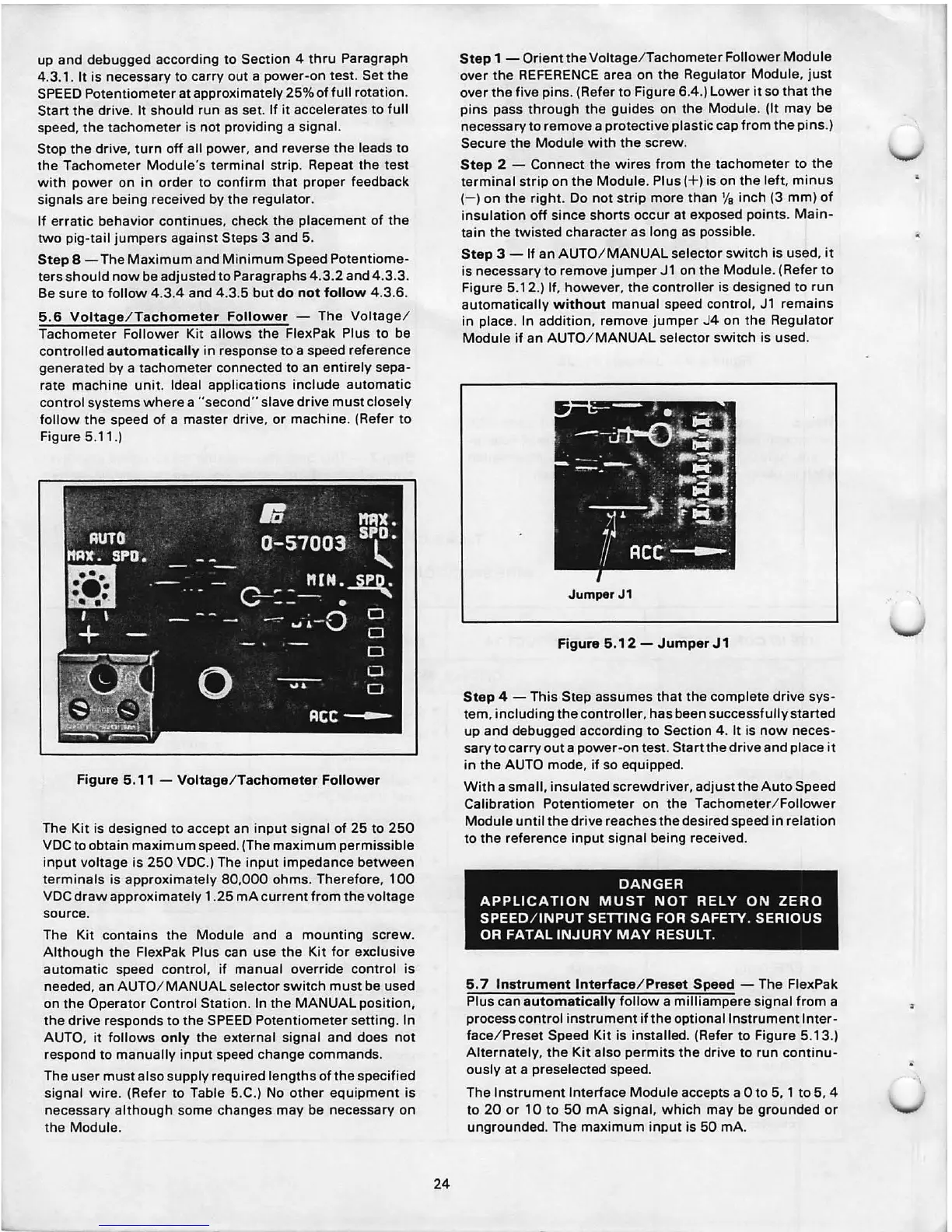

Step 3 - If an AUTO / MANUAL selector switch is used, it

is necessary to remove jumper

Jl on the Module . (Refer to

Figure 5.12.) If, however , the controller is designed to run

automatically

without manual speed cont rol, Jl remains

in place . In addition , remove jumper J4 on the Regulator

Module if an AUTO/ MANUAL selector switch is used.

JumperJ1

Figure 5.12 - Jumper J 1

Step 4 - This Step assumes that the complete drive sys-

tem, including the controller, has been successfully started

up and debugged according to Section 4 . It is now neces -

sary to carry out a power-on test. Start the drive and place it

in the AUTO mode , if so equipped .

With a small, insulated screwdriver , adjust the Auto Speed

Calibration Potentiometer on the Tachometer / Follower

Module until the drive reaches the desired speed in relation

to the reference input signal being received .

DANGER

APPLICATION MUST NOT

RE LY ON ZERO

SPEED / INPUT SETTING FOR SAFETY. SERIOUS

OR FATAL INJURY MAY

RESULT.

5. 7 Instrument Interface / Preset Speed - The FlexPak

Plus can

automatically follow a milliampere signal from a

process control instrument if the optional Instrument Inter-

face / Preset Speed Kit is installed . (Refer to Figure 5.13.)

Alternately , the Kit also perm its the drive to run continu-

ously at a preselected speed.

The Instrument Interface Module accepts a Oto 5, 1 to 5, 4

to 20 or 10 to 50 mA signal, which may be grounded or

ungrounded. The maximum input is 50 mA.

Loading...

Loading...