2.4 .3 Line Impedance Requirements - The FlexPak Plus

controller must be connected to a short-circuit protec tion

syste m design ed to operat e on plant power supplies with

maximum permissible available symmetrical RMS fault

curren ts of 5000 amperes. (Refer to Table 2.D.)

The Basic Contro lle r does not have an M contactor. An M

contactor is requ ired to provide positive power disconnect.

WARNING

THE USER MUST INSTALL AN M CONTACTOR

THAT HAS A 24

voe COIL WITH A MAXIMUM

CURRENT DRAW OF 150 MILLIAMPS . FOR TIM-

ING, A 200 MICROFARAD CAPACITOR MUST BE

INSTALLED WITH CORRECT POLARITY ACROSS

THE RELAY COIL. THE CONTACTOR ADAPTER

KIT MUST BE INSTALLED WITH THE USER'S M

CONTACTOR . (REFER TO TABLE 5 .A AND

PARAGRAPH 5. 14 .) PERSONAL INJURY MAY

OCCUR IF THIS IS NOT INSTALLED.

WARNING

DO NOT OPERATE

THE FLEXPAK PLUS CON-

TROLLER ON POWER SUPPLIES WITH AVAIL-

ABLE SHORT -CIRCUIT CURRENTS IN EXCESS

OF 5000 AMPERES . DAMAGE TO EQUIPMENT

AND PERSONAL INJURY MAY OCCUR.

2.4 .4 Relay Control Circuit -

The regulator board is set

up for use w ith main cont actors having a coil resistance

greater tha n or equal to 100 ohms . The control logic

sequences the contacto r and the control relay on the regu-

lator so that current fl ow thru the main contactor is never

broken in normal operation by the contacts. Refer to Fig-

ures 6. 1, 6.2 and 6.3.

2.4 . 5 A-C Line Fuse Requirements - A-c line protection

is provided when the A uxi liary Panel is specified. The Basic

FlexPak Controller , however , does not include a-c line pro-

tection . Fused a-c line protection mu st be used . Refer to

Table 2.C for proper fuse sizi ng.

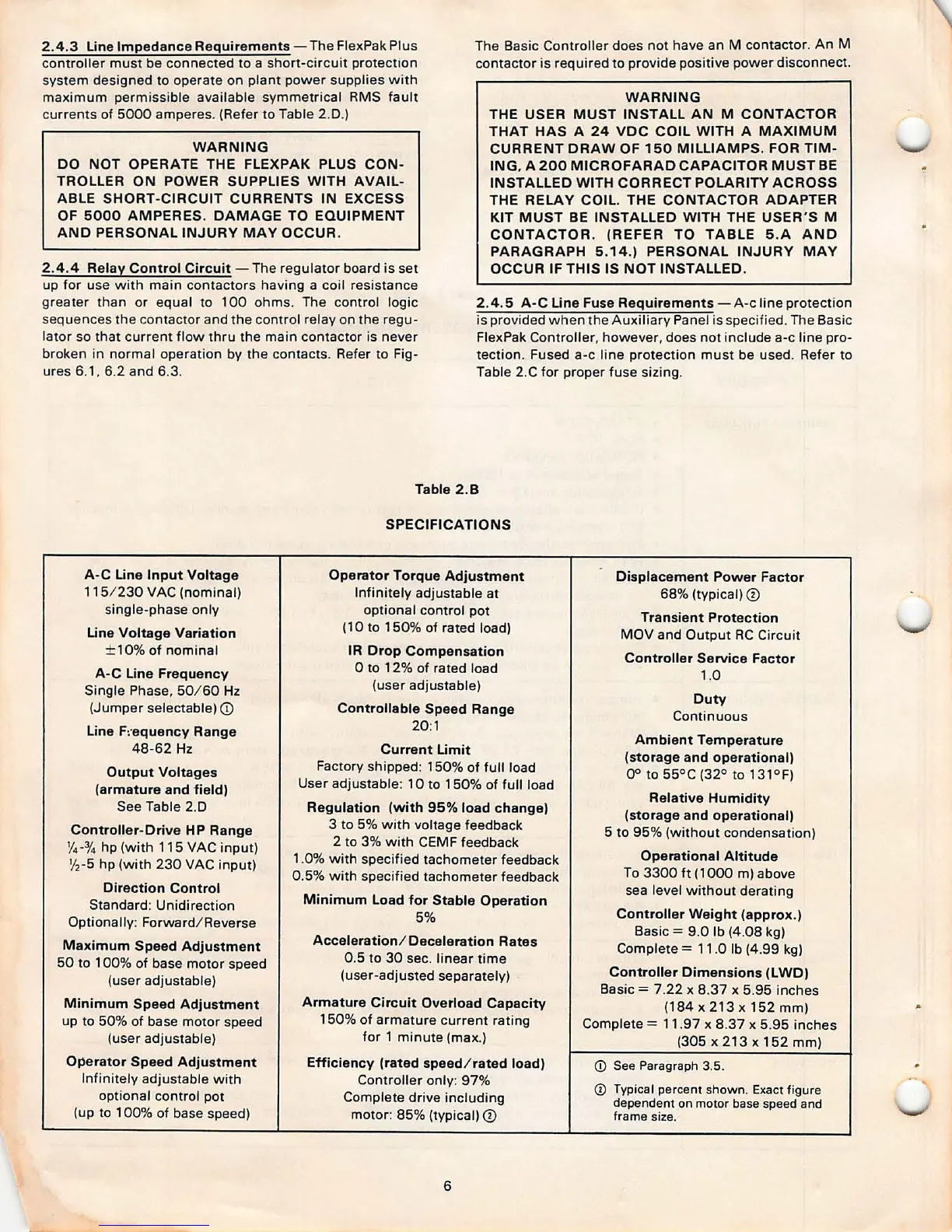

Table 2.B

SPECIFICATIONS

A-C Line Input Voltage

Operator Torque Adjustment

Displacement Power Factor

115/230 VAC (nominal)

Infinitely adjustable at

68% (typical)

CD

single- phase only

optional control pot

Transient Protect ion

Line Voltage Variation

( 10 to 1 50 % of rated load)

MOV and Output RC Circuit

± 10% of nominal

IR Drop Compensation

Controller Service Factor

A-C Line Frequency

0 to 12% of rated load

1 .0

Single Phase, 50/ 60 Hz

(user adjustable)

Duty

(Jumper selectable) CD

Controllable Speed Range

Continuous

Line F:·equency Range

20:1

Ambient Temperature

48-62 Hz

Current Limit

(storage and operational)

Output Voltages

Factory shipped : 150% of full load

00 to 55°C (32° to 131° F)

(armature and field)

User adjustable: 10 to 150 % of full load

See Table 2.D

Regulation (with 95% load change)

Relative Humidity

(storage and operational)

Controller -Drive HP Range

3 to 5% with voltage feedback

5 to 95% (wit hout conde nsation)

Yd'4 hp (with 115 VAC input)

2 to 3% with CEMF feedback

1/

2

-5 hp (with 230 VAC input)

1 .0% with specified tachometer feedback

Operational Altitude

0.5% wit h specified tachometer feedback

To 3300 ft (100 0 m) above

Direction Control

sea level w ithout derating

Standard : Unidirection

Minimum Load for Stable Operation

Optionally: Forward / Reverse

5%

Controller Weight (approx.)

Basic= 9.0 lb (4.08 kg)

Maximum Speed Adjustment

Acceleration / Deceleration Rates

Complete= 1 1 .0 lb (4.99 kg)

50 to 1 00% of base motor speed

0.5 to 30 sec. linear time

(user adjustable)

(user-adjusted separately)

Controller Dimensions (LWD)

Basic= 7.22 x 8.37 x 5.95 inches

Minimum Speed Adjustment

Armature Circuit Overload Capacity

(184 x 213 x 152mm )

up to 50 % of base motor speed

150% of armature current rating

Complete= 11 .97 x 8.37 x 5.95 inches

(user adjustable)

for 1 minute (max.)

(305 x 213 x 152 mm )

Operator Speed Adjustment

Efficiency (rated speed/ rated load)

© See Paragraph 3.5.

Infini tely adjustable with

Controller only : 97%

CD Typical percent shown. Exact figure

optional control pot

Complete drive including

dependent on motor base speed and

(up to 100% of base speed)

motor: 85% (typical)

CD

frame size.

6

Loading...

Loading...