Step 3 - Connect the three -wire harness to the Regulator

Module. Locate the letters AUX. M printed on the Module

near a three-pin connector. (Refer to Figure 6.4.) The con-

nector fits on the bayonet pins. Note that -the yellow (39)

wire

must connect with the pin marked YEL 39 on the

Regulator Module .

Step 4 - Route external wiring to the Module 's terminal

block . Do not strip more than

% inch (6 mm) of insulation

from the wires since shorts could occur at exposed points .

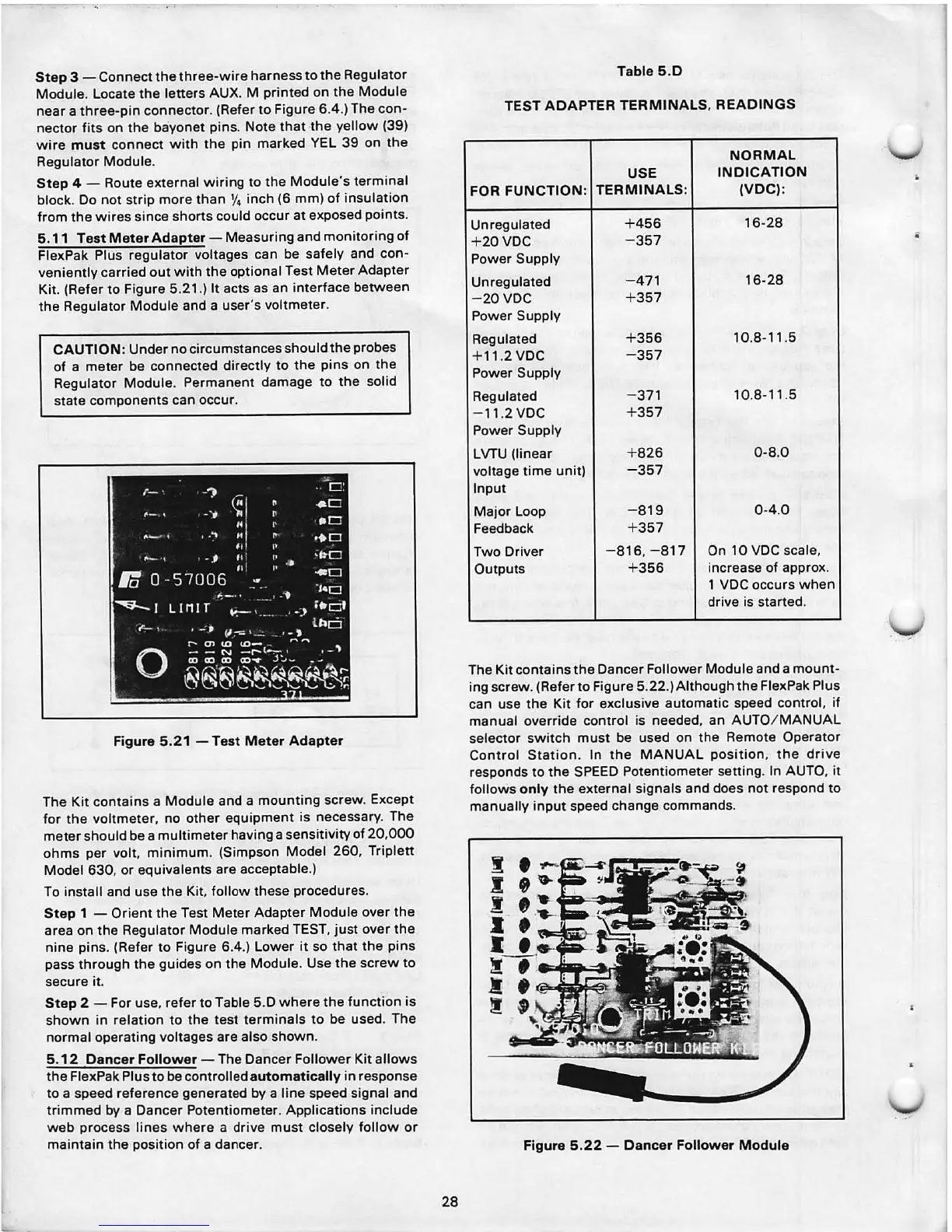

5.11 Test Meter Adapter - Measuring and monitoring of

FlexPak Plus regulator voltages can be safely and con-

veniently carried out with the optional Test Meter Adapter

Kit. (Refer to Figure 5.21.) It acts as an interface between

the Regulator Module and a user's voltmeter .

CAUTION : Undernocircumstancesshouldtheprobes

of a meter be connected directly to the pins on the

Regulator Module . Permanent damage to the solid

state components can occur .

Figure 5.21 -Test Meter Adapter

The Kit contains a Module and a mounting screw . Except

for the voltmeter , no other equipment is necessary. The

meter should be a multimeter having a sensitivity of 20,000

ohms per volt , minimum. (Simpson Model 260 , Triplett

Model 630, or equivalents are acceptable.)

To install and use the Kit, follow these procedures.

Step 1 - Orient the Test Meter Adapter Module over the

area on the Regulator Module marked TEST, just over the

nine pins . (Refer to Figure 6.4.) Lower it so that the pins

pass through the guides on the Module. Use the screw to

secure it.

Step 2 - For use, refer to Table 5.D where the function is

shown in relat ion to the test terminals to be used. The

normal operating voltages are also shown .

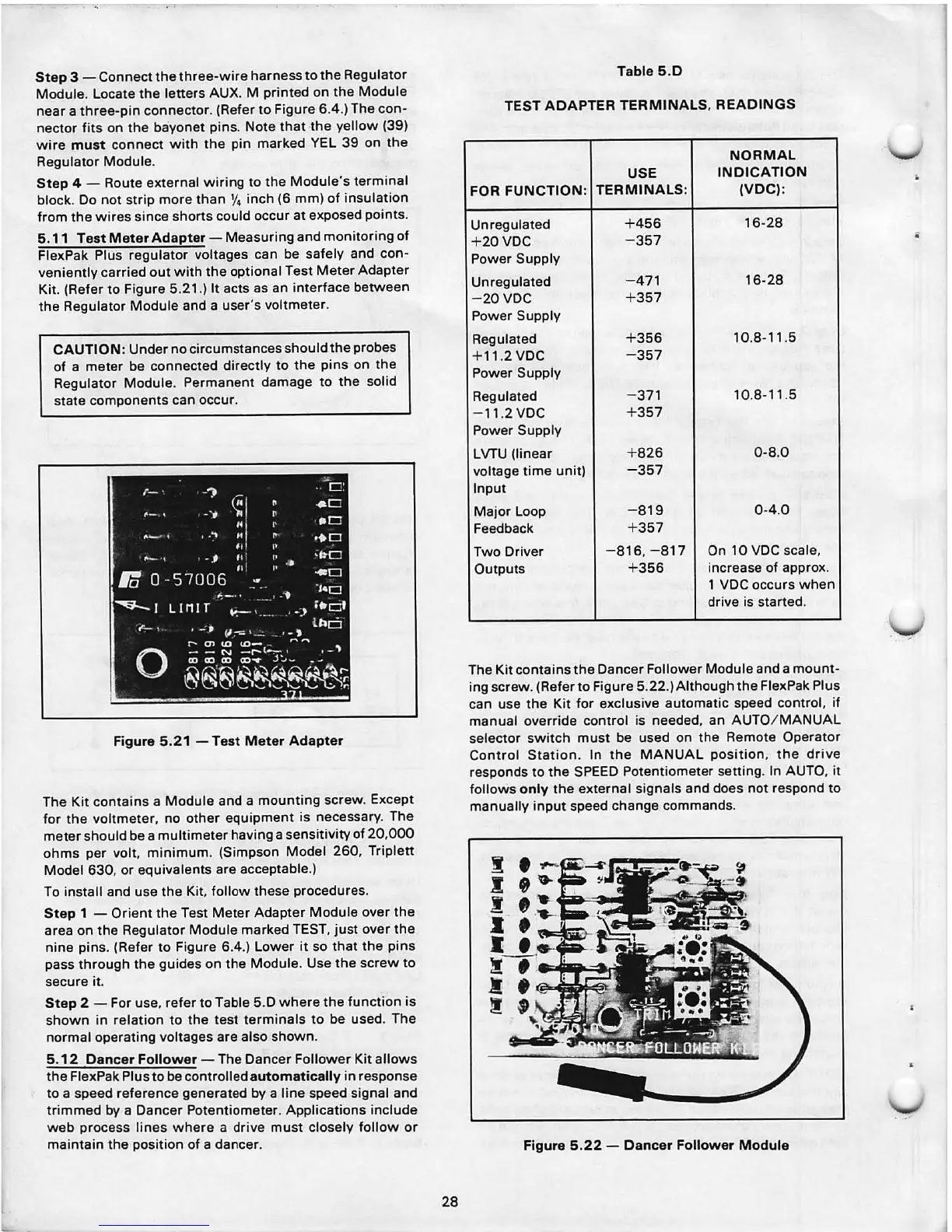

5.12 Dancer Follower - The Dancer Follower Kit allows

the FlexPak Plus to be controlled

automatically in response

to a speed reference generated by a line speed signal and

trimmed by a Dancer Potentiometer . Applications include

web process lines where a drive must closely follow or

maintain the position of a dancer .

28

Table 5 .0

TEST ADAPTER TERMINALS , READINGS

NORMAL

USE

INDICATION

FOR FUNCTION:

TERMINALS:

(VDC) :

Unregulated

+ 456

16-28

+20VDC

-357

Power Supply

Unregulated

-471

16-28

-20VDC

+ 357

Power Supply

Regulated

+ 356

10.8-11 .5

+ 11.2VDC

-357

Power Supply

Regulated

-371 10.8-11.5

-11 .2VDC

+ 357

Power Supply

LVTU (linear + 826

0-8 .0

voltage time unit)

-357

Input

Major Loop

-819

0-4 .0

Feedback

+ 357

Two Driver

-816 , -817 On 10 VDC scale,

Outputs

+ 356

increase of appro x.

1

voe occurs when

drive is started .

The Kit contains the Dancer Follower Module and a mount-

ing screw . (Refer to Figure 5.22.)Although the Flex Pak Plus

can use the Kit for exclusive automatic speed control , if

manual override control is needed, an AUTO / MANUAL

selector switch must be used on the Remote Operator

Control Station. In the MANUAL pos ition, the drive

responds to the SPEED Potent iomete r setting . In AUTO , it

follows

only the external signa ls and does not respond to

manually input speed change commands .

Figure 5.22 - Dancer Follower Module

Loading...

Loading...