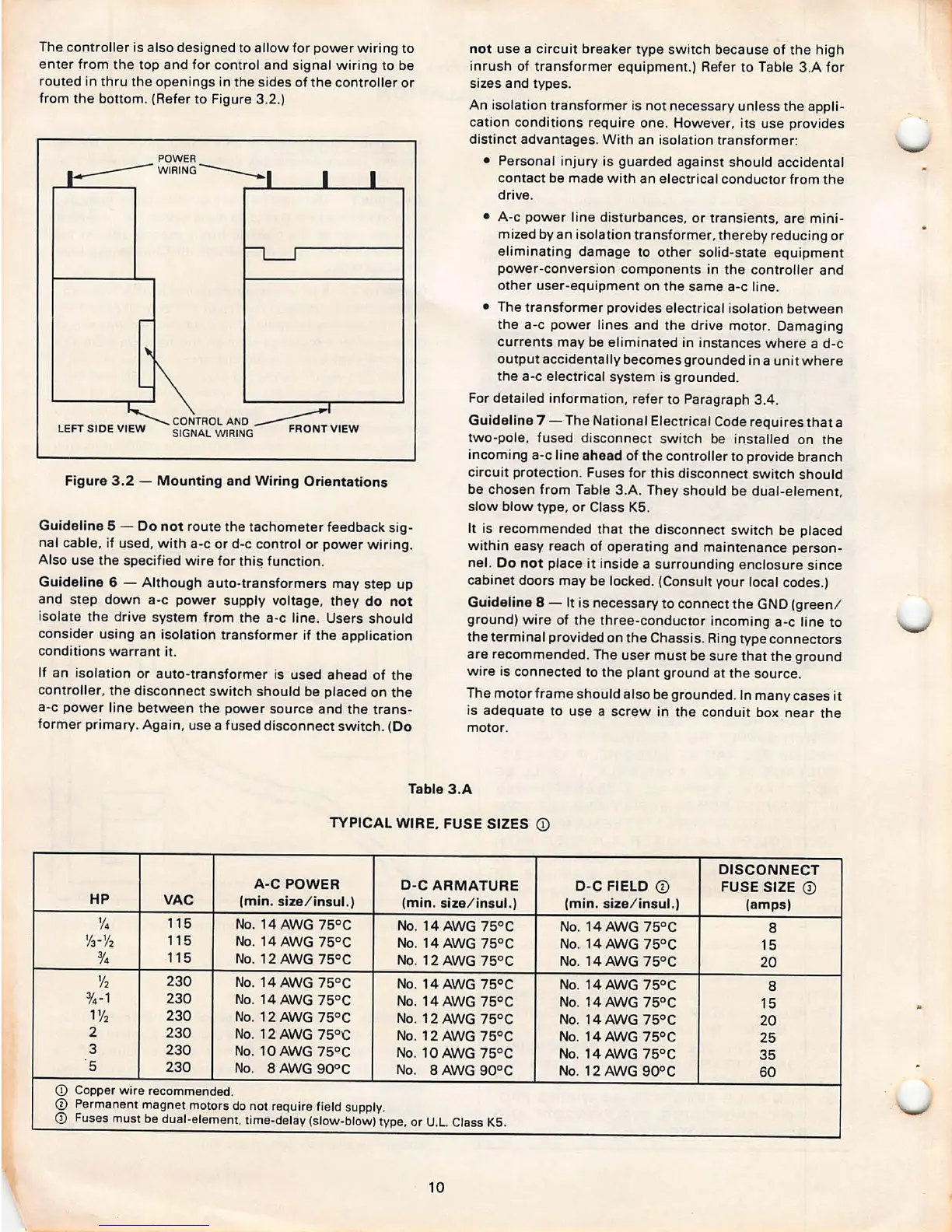

The controller is also designed to allow for power wiring to

enter from the top and for control and signal wiring to be

routed in thru the openings in the sides of the controller or

from the bottom . (Refer to Figure 3.2.)

POWER

WIRING

-----

CONTROL A ND

~

SIGNAL WIRING FRONT VIEW

Figure 3 .2 - Mounting and Wiring Orientations

Guideline

5 - Do not route the tachometer feedback sig-

nal cable, if used, with a-c or d-c control or power wiring.

Also use the specified wire for

thi~ function .

Guideline 6 - Although auto -transform ers may step up

and step down a-c power supply voltage, they

do not

isolate the drive system from the a-c line . Users should

consider using an isolation transformer if the application

conditions warrant it.

If an isolation or auto-transformer is used ahead of the

controller , the disconnect sw itch should be placed on the

a-c power line between the power source and the trans-

former primary . Again , use a fused disconnect switch.

(Do

not

use a circuit breaker type switch because of the high

inrush of transformer equipment.) Refer to Table 3.A for

sizes and types .

An isolation transformer is not necessary unless the appli-

cation conditions require one. However . its use provides

distinct advantages . With an isolation transformer :

• Personal injury is guarded against should accidental

contact be made with an electrical conductor from the

drive.

• A-c power line disturbances , or transients , are mini-

mized by an isolation transformer , thereby reducing or

eliminating damage to other solid-state equipment

power-conversion components in the controller and

other user-equipment on the same a-c line.

• The transformer provides electrical isolation between

the a-c power lines and the drive motor . Damaging

currents may be eliminated in instances where a d-c

output accidentally becomes grounded in a unit where

the a-c electrical system is grounded.

For detailed information. refer to Paragraph 3.4 .

Guideline 7 - The National Electrical Code requires that a

two-pole, fused dis connect swit ch be installed on the

incoming a-c line

ahead of the controller to provide branch

circuit protection . Fuses for this disconnect switch should

be chosen from Table 3.A. They should be dual-element,

slow blow type. or Class K5.

It is recommended that the disconnect switch be placed

within easy reach of operating and maintenance person-

nel.

Do not place it inside a surrounding enclosure since

cabinet doors may be locked . (Consult your local codes .)

Guideline 8 - It is necessary to connect the GND (green /

ground) wire of the three-conductor incoming a-c line to

the terminal provided on the Chassis. Ring type connectors

are recommended . The user must be sure that the ground

wire is connected to the plant ground at the source.

The motor frame should also be grounded . In many cases it

is adequate to use a screw in the conduit box near the

motor .

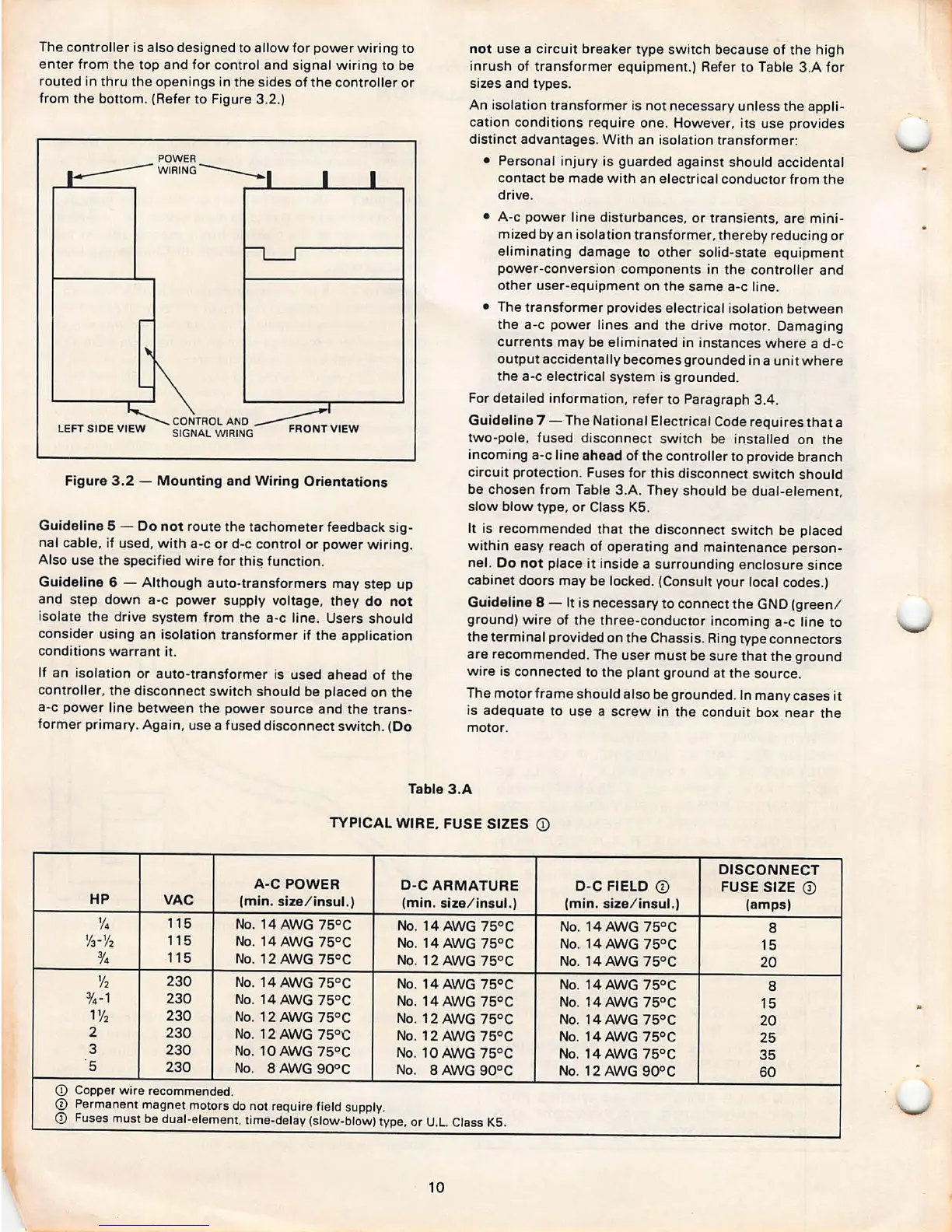

Table 3.A

TYPICAL WIRE. FUSE SIZES

(D

DISCONNECT

A-C POWER

D-C ARMATURE

D-C FIELD

(D

FUSE SIZE (D

HP

VAC

(min. size / insul.)

(min. size/ insul.) (min . size / insul .)

(amps)

1/4

115

No. 14 AWG 75°C

No. 14 AWG

75°C

No. 14 AWG 75°C

8

1/rY2

115

No. 14 AWG 75°C

No. 14 AWG 75° C No. 14 AWG 75 °C

15

%

115

No. 12AWG75°C

No. 12 AWG 75°C

No. 14 AWG 75°C

20

%

230

No. 14 AWG 75°C

No. 14 AWG 75°C

No. 14 AWG 75°C

8

%- 1

230

No. 14 AWG 75°C

No. 14AWG 75°C

No. 14 AWG 75° C

15

1% 230

No. 12 AWG 75 °C

No. 12 AWG

75°C

No. 14 AWG 75°C

20

2

230

No. 12 AWG

75°C

No. 12 AWG 75°C

No. 14 AWG 75° C

25

3

230

No. 10 AWG 75°C

No. 10 AWG 75 °C

No. 14 AWG 75° C

35

5

230

No.

BAWG 90 °C

No.

BAWG 90°C

No. 12 AWG 90° C

60

CD Copper wire recommended.

CD Permanent magnet motors do not require field supply.

0 Fuses must be dual-element, time-delay (slow-blow) type, or U.L. Class K5.

10

Loading...

Loading...