The Kit contains a single Module with a fixed wire harness.

However, its use requires that two other options also be

used:

• Auxiliary Panel

• Reversing Contactor

No other parts are required, and no modifications need be

made to the controller beyond those implied in the above

two options.

To install the Kit, follow these procedures.

Step 1 - Install the Auxiliary Panel and the Reversing

Contactor, as outlined in Paragraphs 5.1 and 5.3.

Step 2 - On the right-hand end of the Auxiliary Mounting

Bracket, orient the Automatic Reversing Module so that the

harness points toward the Regulator Module. (Refer to

Figure 2.2.) Press the four nylon pins firmly into the four

holes in the Auxiliary Mounting Bracket.

Step 3 - Place the harness connector over the Regulator

Module pins marked AUTO REV. (Refer to Figure 6.4.)

Orientation is important: connect the purple (40) wire with

the pin called out as PUR on the Regulator Module.

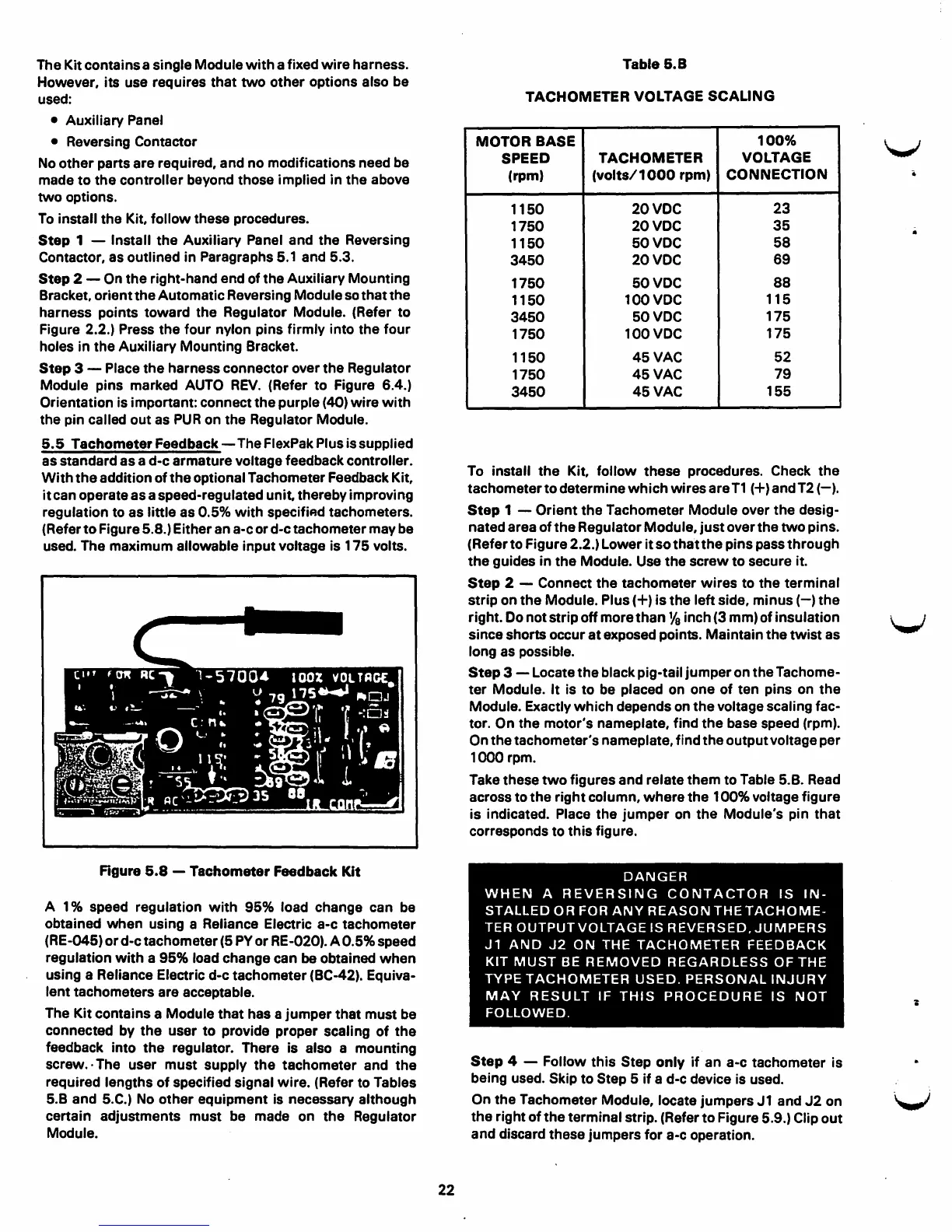

5.5 Tachometer Feedback - The FlexPak Plus is supplied

as standard as a d-c armature voltage feedback controller.

With the addition of the optional Tachometer Feedback Kit,

it can operate as a speed-regulated unit, thereby improving

regulation to as little as 0.5% with specifiAd tachometers.

(Refer to Figure 5.8.) Either an a-c or d-c tachometer may be

used. The maximum allowable input voltage is 175 volts.

Figure 5.8 - Tachometer Feedback Kit

A 1 % speed regulation with 95% load change can be

obtained when using a Reliance Electric a-c tachometer

(RE-045) or d-c tachometer (5 PY or RE-020). A 0.5% speed

regulation with a

95% load change can be obtained when

using a Reliance Electric d-c tachometer (BC-42). Equiva-

lent tachometers are acceptable.

The Kit contains a Module that has a jumper that must be

connected by the user to provide proper scaling of the

feedback into the regulator. There is also a mounting

screw.· The user must supply the tachometer and the

required lengths of specified signal wire. (Refer to Tables

5.B and 5.C.) No other equipment is necessary although

certain adjustments must be made on the Regulator

Module.

22

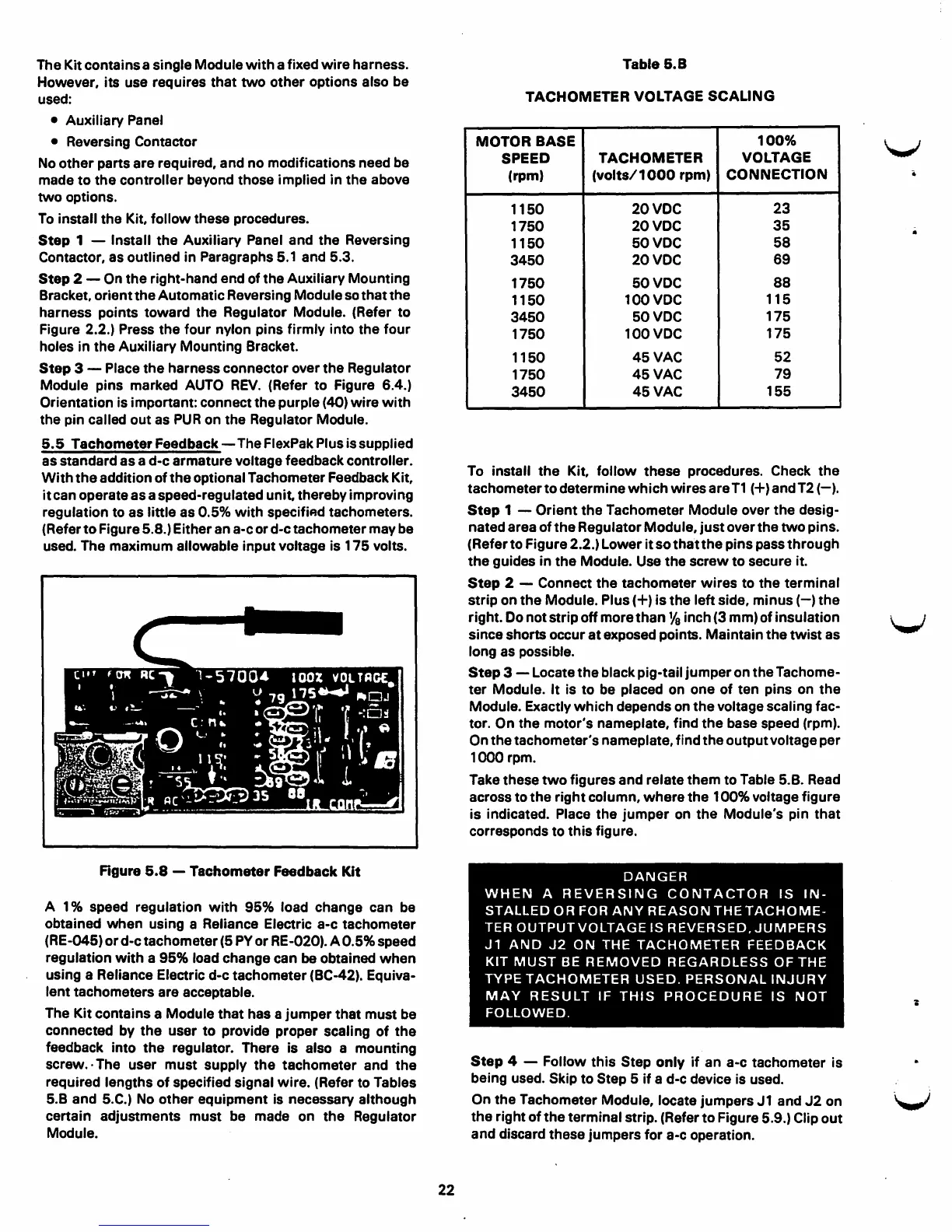

Table 5.8

TACHOMETER VOLTAGE SCALING

MOTOR

BASE

100%

SPEED

TACHOMETER

VOLTAGE

(rpm)

(volts/ 1000 rpm)

CONNECTION

1150

20VOC

23

1750

20VDC

35

1150

50VDC

58

3450

20VOC

69

1750

50VDC

88

1150

100VDC

115

3450

50VDC

175

1750

100VDC

175

1150

45VAC

52

1750

45VAC

79

3450

45VAC

155

To install the Kit, follow these procedures. Check the

tachometer to determine which wires are T1 (+) and T2 (-).

Step 1 - Orient the Tachometer Module over the desig-

nated area of the Regulator Module, just over the two pins.

(Refer to Figure 2.2.) Lower it so that the pins pass through

the guides in the Module. Use the screw to secure it.

Step 2 - Connect the tachometer wires to the terminal

strip on the Module. Plus(+) is the left side, minus(-) the

right. Do not strip off more than

Ya inch (3 mm) of insulation

since shorts occur at exposed points. Maintain the twist as

long as possible.

Step 3 - Locate the black pig-tail jumper on the Tachome-

ter Module. It is to be placed on one of ten pins on the

Module. Exactly which depends on the voltage scaling fac-

tor. On the motor's nameplate, find the base speed (rpm).

On the tachometer's nameplate, find the output voltage per

1000 rpm.

Take these two figures and relate them to Table 5.B. Read

across to the right column, where the 100% voltage figure

is indicated. Place the jumper on the Module's pin that

corresponds to this figure.

DANGER

WHEN A REVERSING CONTACTOR IS IN-

STALLED OR FOR ANY REASON THE TACHOME-

TER OUTPUT VOLTAGE IS REVERSED.JUMPERS

J1 AND J2 ON THE TACHOMETER FEEDBACK

KIT MUST BE REMOVED REGARDLESS OF THE

TYPE TACHOMETER USED. PERSONAL INJURY

MAY RESULT IF THIS PROCEDURE IS NOT

FOLLOWED.

Step 4 - Follow this Step only if an a-c tachometer is

being used. Skip to Step 6 if a d-c device is used.

On the Tachometer Module, locate jumpers J 1 and J2 on

the right of the terminal strip. (Refer to Figure 5.9.) Clip out

and discard these jumpers for a-c operation.

V

V

V

Loading...

Loading...