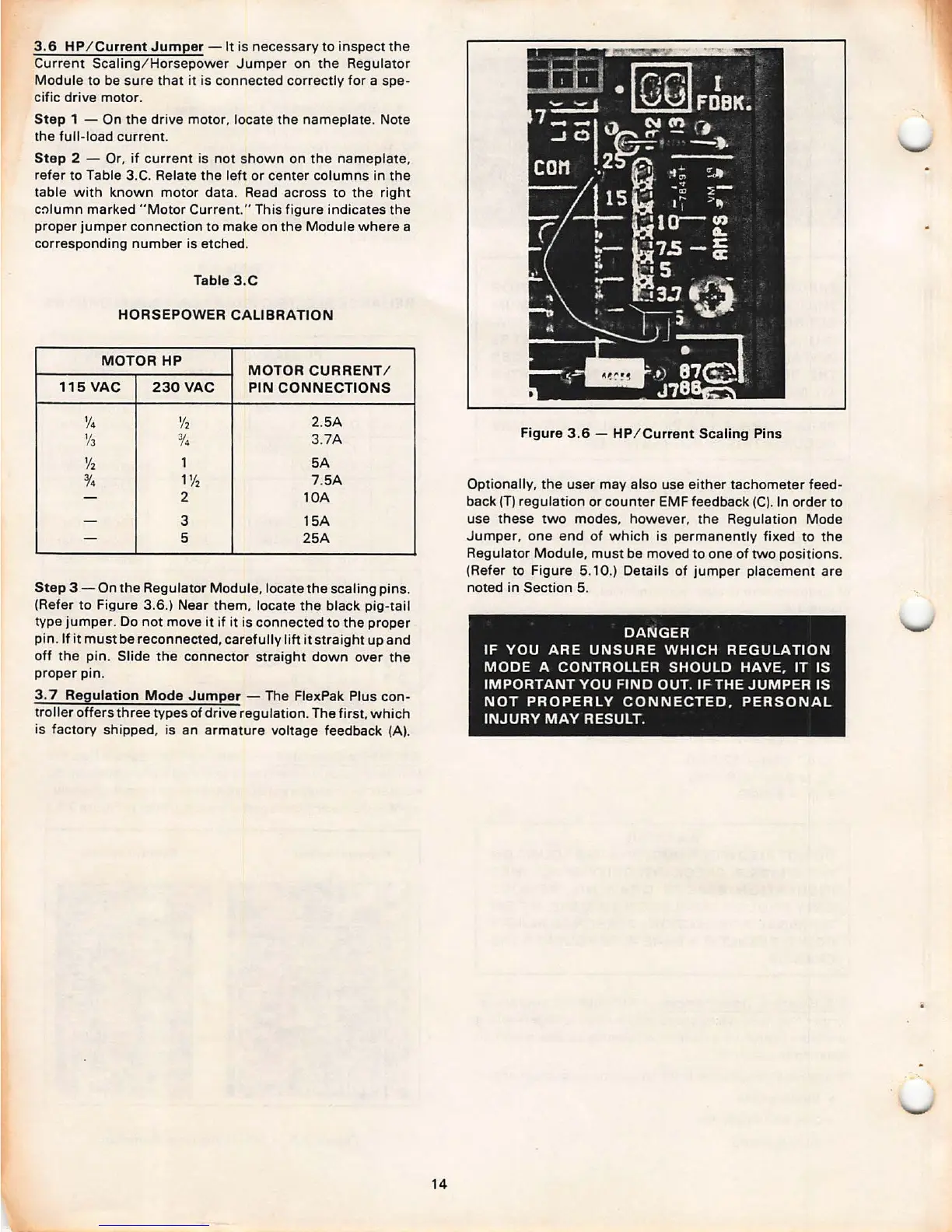

3.6 HP/ Current Jumper - It is necessary to inspect the

Current Scaling / Horsepower Jumper on the Regulator

Module to be sure that it is connected correctly for a spe-

cific drive motor .

Step 1 - On the drive motor , locate the nameplate. Note

the full-load current .

Step 2 - Or, if current is not shown on the nameplate ,

refer to Table 3.C. Relate the left or center columns in the

tab le with known motor data . Read across to the right

cnlumn marked "Motor Current ." This figure indicates the

proper jumper connection to make on the Module where a

corresponding number is etched .

Table 3.C

HORSEPOWER CALIBRATION

MOTOR HP

MOTOR CURRENT /

115 VAC 230 VAC

PIN CONNECTIONS

1/4

1/2

2.5A

1/3 314

3.7A

Yi

1 5A

7'4

11/2

7.5A

-

2

10A

- 3

15A

- 5

25A

Step

3 - On the Regulator Module , locate the scaling pins .

(Refer to Figure

3.6.) Near them, locate the black pig-tail

type jumper . Do not move it if it is connected to the proper

pin . If it must be reconnected, carefully lift it straight up and

off the pin. Slide the connector straight down over the

proper pin.

3. 7 Regulation Mode Jumper - The FlexPak Plus con-

troller offers three types of drive regulation. The first , which

is factory shipped , is an armature voltage feedback

(A).

14

Figure 3.6 - HP/ Current Scaling Pins

Optionally , the user may also use either tachometer feed-

back (T) regulation or counter EMF feedback

(C). In order to

use these two modes , however, the Regulation Mode

Jumper, one end of which is permanently fixed to the

Regulator Module, must be moved to one of two positions .

(Refer to Figure

5. 10.) Details of jumper placement are

noted in Section 5.

DANGER

IF YOU ARE UNSURE WHICH REGULATION

MODE A CONTROLLER SHOULD HAVE.

IT IS

IMPORTANT YOU FIND OUT. IF THE JUMPER IS

NOT PROPERLY CONNECTED. PERSONAL

INJURY MAY RESULT.

Loading...

Loading...