' .

The Kit consists of a Module and a mounting screw. No

other equipment is required . However, the SPEED Potenti-

ometer and either the TORQUE Potentiometer or the Cur-

rent Limit Potentiometer on the Regulator Module are used

in conjunction with the two potentiometers on the Module .

To install the Kit and to make initial adjustments , follow

these procedures .

Step 1 - Remove jumpers J7 and JS on the Regulator

Module . (Refer to Figure 6.4 .)

Step 2 - Orient the Module over the area marked TORQUE

TAPER on the Regulator Module , just over the seven pins.

(Refer to Figure 6.4.) Lower it so that the pins pass through

the guides in the Module. Use the mounting screw to

secure it.

Step 3 - On the Regulator Module , adjust the Current

Limit Potentiometer CCW to 100% , or lower. depending on

the application . Remember that it is factory-shipped at

150 %. Dot No. 4 is approximately 100% . (Refer to Figure

4.1 .)

Step 4 - On the Torque Taper Module, turn the CORE

TORQUE Potentio meter completely CCW. The core torque

setting provides a minimum winding torque, or minimum

strip tension, when the winding cycle begins .

Step 5 - On the Torque Taper Module, turn the Torque

Taper Potentiometer completely CW. This assures that

excessive tension will not develop as the first coil or pack-

age is wound.

Step 6 - This Step assumes that the complete drive sys-

tem, including the controller, has been successfully started

up and debugged according to Section

4. It is now neces-

sary to carry out a power-on test . Thread the strip onto the

winder and securely fasten it to the core. Remove all strip

slack before the drive is restarted .

Step 7 - Set the SPEED Potentiometer for a safe maxi-

mum winder speed.

Step 8 - Start the drive . If the strip or web breaks imme-

diately , stop it. Reduce the Current Limit Potentiometer

setting on the Regulator Module . (CCW decreases current,

here torque .)

If the strip does not immediately break, start the process

and allow the winder to begin winding . Accelerate it to

normal running speed. On the Torque Taper Module, adjust

the CORE TORQUE Potentiometer to obtain the desired

strip tension at the beginning of the coil. (CCW decreases,

CW increases .)

Step 9 - As the coil or package increases in diameter,

adjust the TORQUE TAPER Potentiometer on the Torque

Module to maintain proper tension . (CCW increases cur-

rent , here torque .) Adjust in small increments as the diam-

eter grows.

An ammeter in the armature circuit is useful when adjust-

ing both potentiometers on the Module . Observing the

ammeter, which shows current, and the growing coil di-

ameter gives visual confirmation that current (torque) is

increasing too fast or slow in relation to the build-up .

NOTE: Depending on the amount of torque taper desired

and the size of the coil or package being wound, the drive

may go into current limit. However.

at no time should the

Current Limi t Potentiometer on the Regulator Module be

set higher than 100% of the nameplate rating on the motor .

27

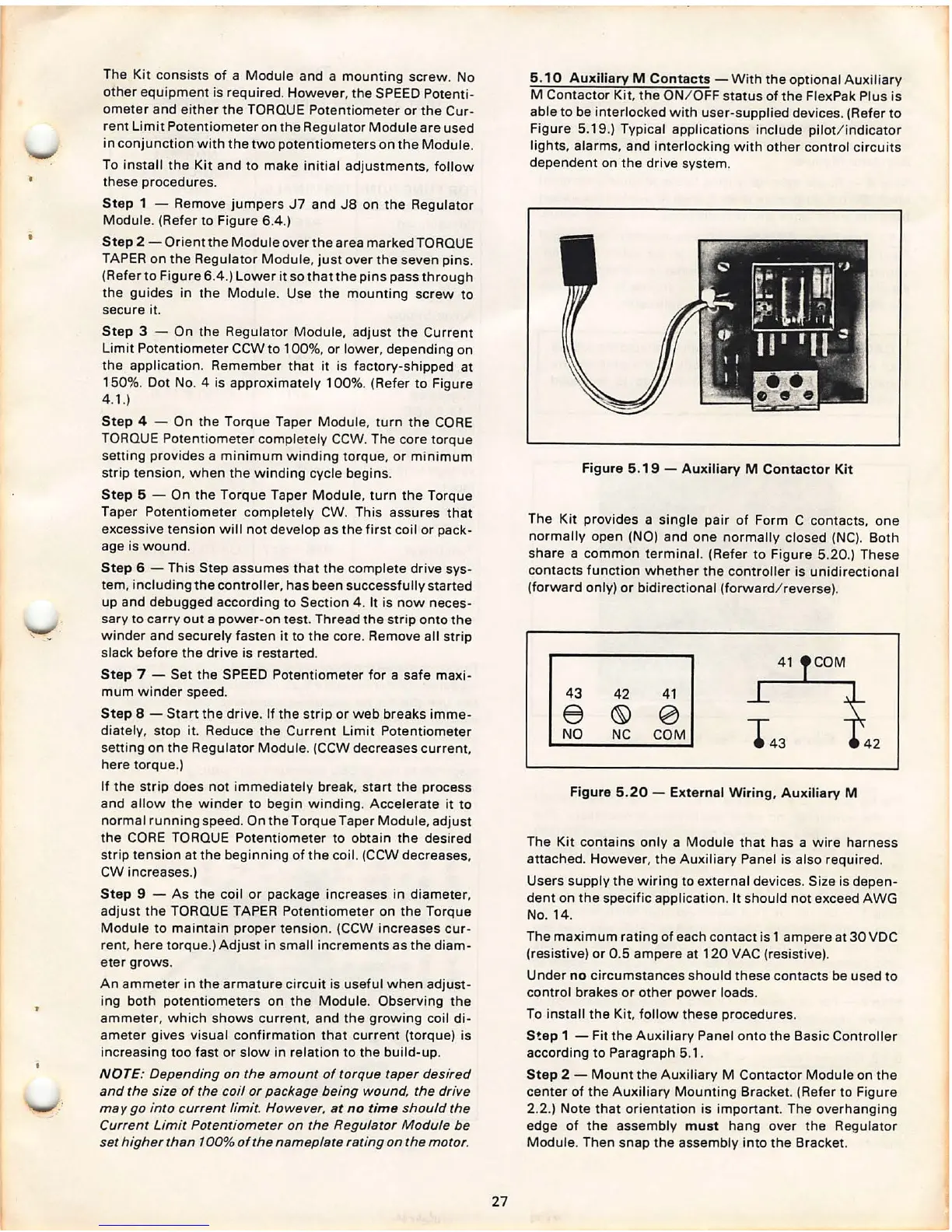

5.10 Auxiliary M Contacts - With the optional Auxiliary

M Contactor Kit, the ON/ OFF status of the FlexPak Plus is

able to be interlocked with user-supplied devices . (Refer to

Figure 5.19.) Typical applications include pilot /i ndicator

lights, alarms , and interlocking with other control circuits

dependent on the drive system.

Figure 5 .19 - Auxiliary M Contactor Kit

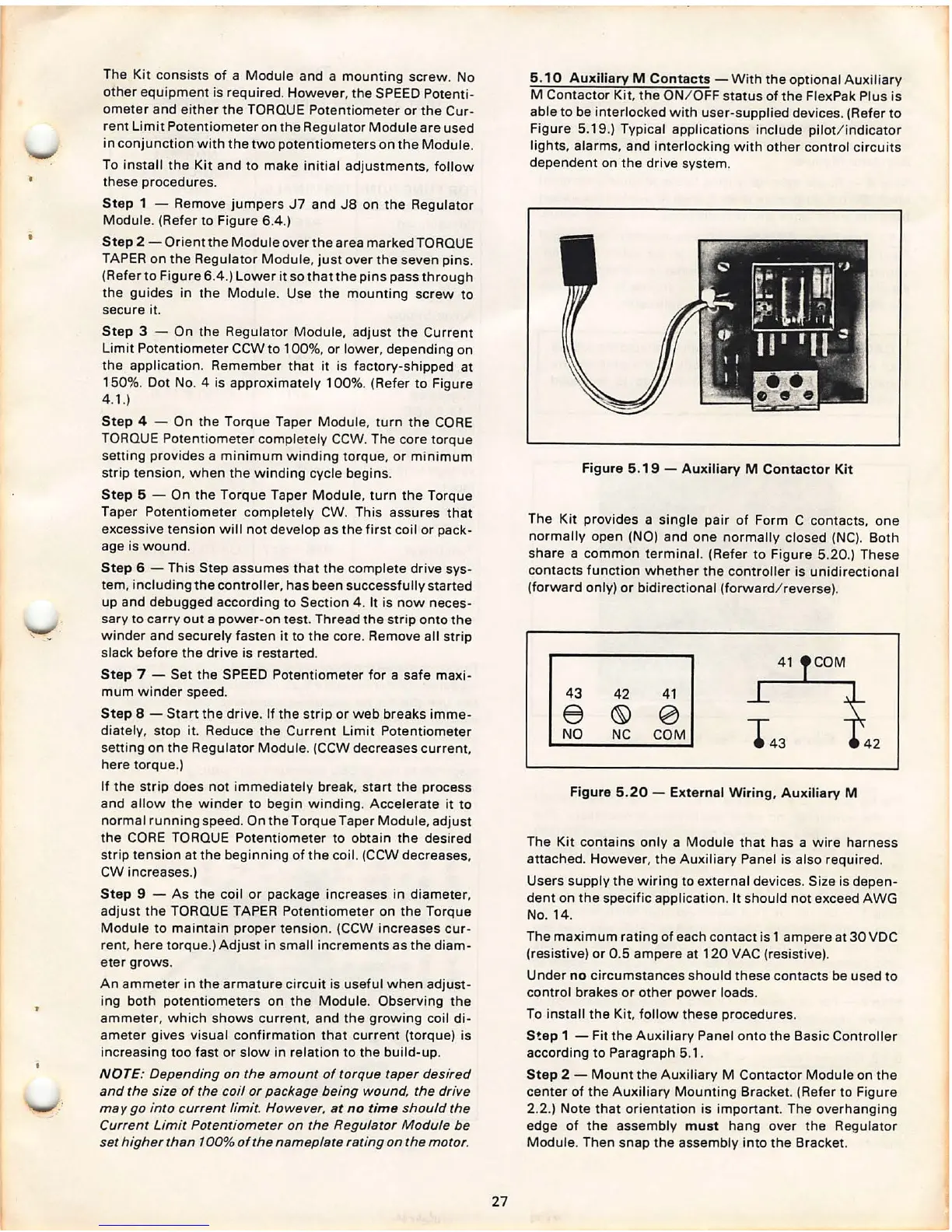

The Kit provides a single pair of Form C contacts , one

normally open

(NO) and one normally closed (NC). Both

share a common terminal. (Refer to Figure 5.20.) These

contacts function whether the controller is unidirectional

(forward only) or bidirectional (forward / reverse) .

41 COM

43

42 41

e

© 0

NO

NC COM

Figure 5.20 - External Wiring, Auxiliary M

The Kit contains only a Module that has a wire harness

attached. However , the Auxiliary Panel is also required .

Users supply the wiring to external devices. Size is depen-

dent on the specific application . It should not exceed AWG

No. 14.

The maximum rating of each contact is 1 ampere at 30 VDC

(resistive) or 0 .5 ampere at 120 VAC (resistive).

Under

no circumstances should these contacts be used to

control brakes or other power loads.

To install the Kit. follow these procedures .

S!ep 1 - Fit the Auxiliary Panel onto the Basic Controller

according to Paragraph 5.1 .

Step 2 - Mount the Aux iliary M Contactor Module on the

center of the Auxiliary Mounting Bracket. (Refer to Figure

2.2.) Note that orientation is important. The overhanging

edge of the assembly

must hang over the Regulator

Module . Then snap the assembly into the Bracket.

Loading...

Loading...