Step 4 - Place the controller in the AUTO mode, if so

equipped . Locate the Auto Maximum Speed Potentiometer.

Adjust it to obtain the desired preset speed. (CW increases

speed, CCW decreases it.)

5.8 Field Supply - The Field Supply Kit provides full-

wave field excitation for shunt -wound d-c motors . (Refer to

Figure 5.15.) It may be optionall y applied to controll ers from

% thru 11f2 hp. (It is a standa rd feature for 3 and 5 hp FlexPak

Plus controllers .)

Figure 5.15 - Field Supply Kit

D-c field supply voltage and maximum field amperes are

listed in Table 2.0 .

The Kit is an assembly consisting of a terminal block , a Field

Supply Power Cube, two wire harnesses , and two screws .

The user provides the F1 / F2 conductors to the drive motor .

No other equipment is required.

To install the

Kit. follow these procedures .

Step 1 - Mount the Field Supply Power Cube on the

right-hand edge of the terminal board bracket of the Basic

Controller . Use the long taptite screw and nylon washer

provided . Attach the F1, F2 terminal board to the terminal

board labeled 32, 132 .

Step 2 -Wire from the Field Supply Pow er Cube to termi-

nals 51 and 52 on 1TB, as shown in Figure 5.16.

Step 3 - The user-supplied field wir ing conductors should

be drawn into the Chassis. Route them as indicated in

Figure 3.4. Move them to the upper screws on 2TB and

connect F1 / F2 according to the label or Figure 5.16.

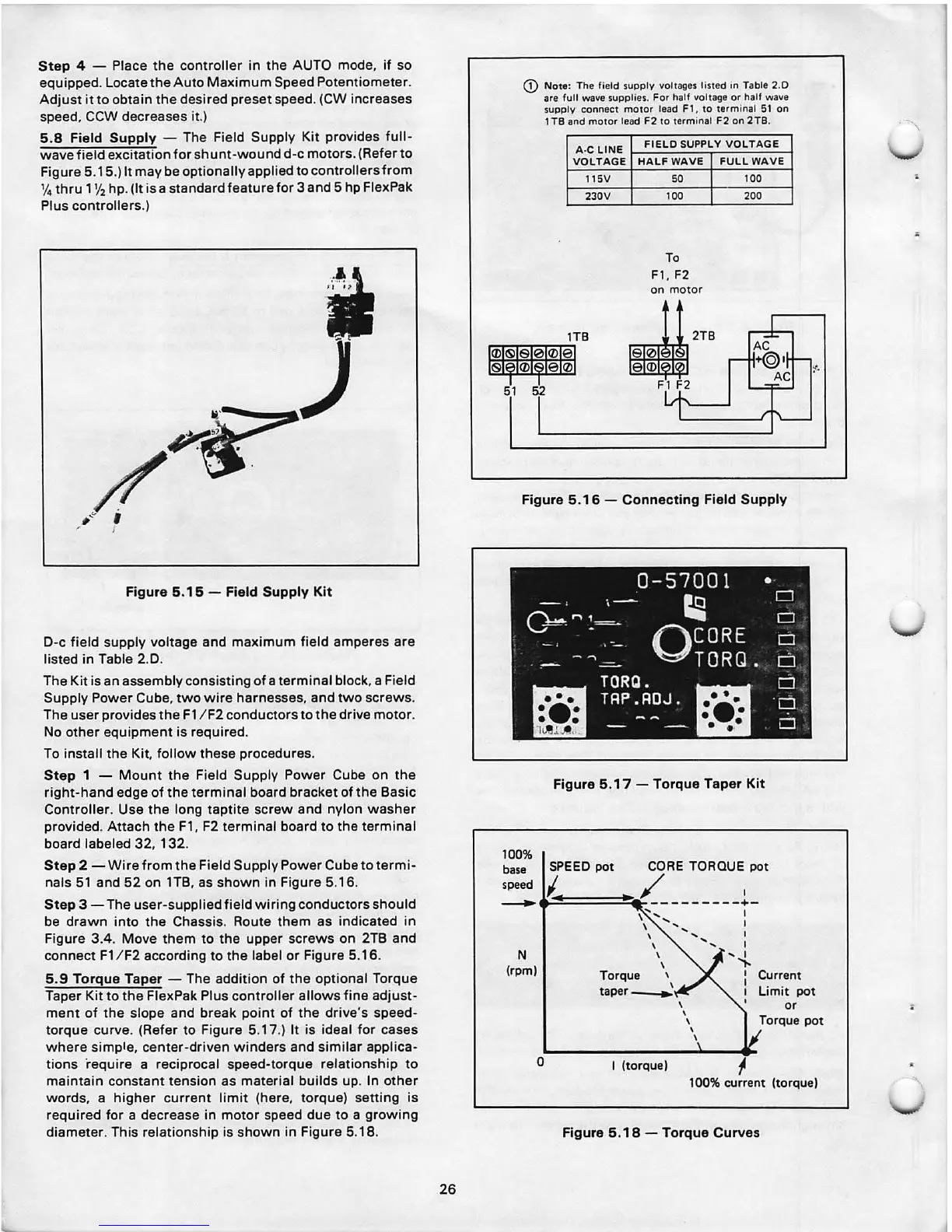

5.9 Torque Taper - The addit ion of the optional Torque

Taper Kit to the FlexPak Plus controller allows fine adjust-

ment of the slope and break point of the drive 's speed-

torque curve . (Refer to Figure 5.17.) It is ideal for cases

whe re simple , center-driven winders and similar applica-

tions require a rec iprocal speed-torque relat ionsh ip to

maintain constant tension as material builds up. In oth er

words , a higher current limit (here , torque) setting is

required for a decrease in motor speed due to a growing

diameter . This relation ship is shown in Figure 5.18.

26

51

G) Not e: The fie ld supp ly voltages liste d in Table 2.0

are full w ave supplies. For half voltage or half wave

supply conn ect mo tor lead Fl , to terminal

51 on

1 TB and moto r lead F2 to term inal F2 on 2 TB.

A·C LINE

FIELD SUPPL Y VOLT AGE

VOLTAGE HALF WAVE FULL WAVE

115V so

100

230V 100 200

To

Fl , F2

on motor

~ 2TB

0

<D

52

Fl F2

Figure 5. 16 - Connecting Field Supply

Figure 5.17 - Torque Taper Kit

100%

base SPEED pot CORE TORQUE pot

~

41/_~===::::!~~ -------t -

N

(rpm)

0

\ ',, I

\ '' I

\ ..............

\

\

Torque ,

taper~

I (torque)

\

\

\

\

\

,

Current

Limit pot

or

Torqu e pot

100% current (torque)

Figure 5.18 - Torque Curves

'

•

Loading...

Loading...