i

i

'--.

2.4 Specifications - The mor e important specifications

for the FlexPak Plus controller are listed in Table 2.8. Refer

also to Table 2.D where other ratings are indicated in rela-

tion to d-c motors of specific horsepower.

However , for optimum 50-Hz operation. it is recommended

that two resistors be removed from the Regulator Module .

(Complete deta ils are given at Paragraph 3.5.) If the resis -

tors are not removed , there is a slight loss of performance .

2.4.1 Line Frequency - The FlexPak Plus controller is

able to operate without modification from a single-phase

power source having a frequency range from 48 to 62 Hz.

2.4.2 Voltage Tolerance - The FlexPak Plus controller

delivers output current and voltage, as listed in Table 2.D. It

will also operate within these regulation specifications

even with incoming line voltag e at

± 10% of nominal.

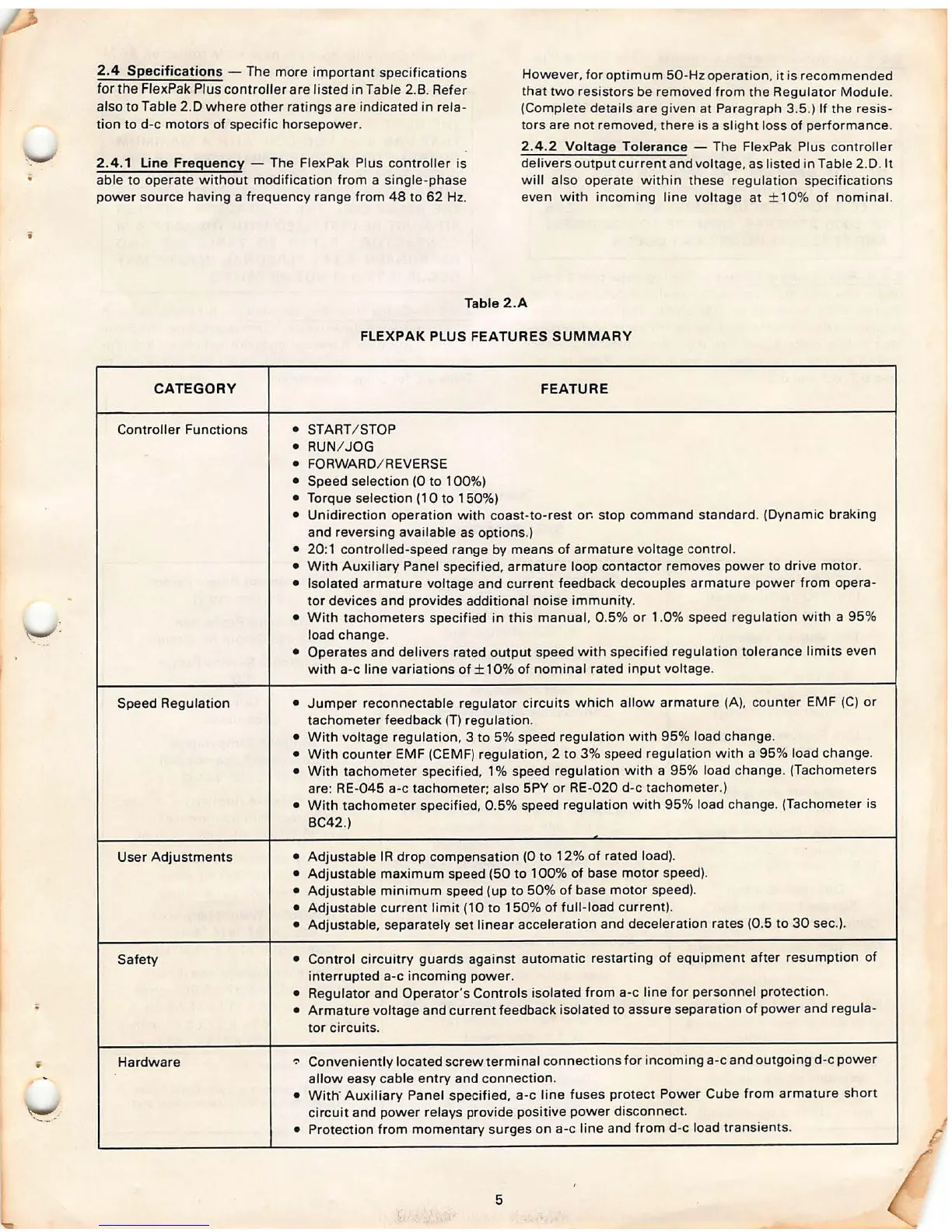

Table 2.A

FLEXPAK PLUS FEATURES SUMMARY

CATEGORY FEATURE

Controller Functions

• ST ART / STOP

• RUN/ JOG

• FOR\NARD/ REVERSE

• Speed selection (0 to 100%)

• Torque selection ( 1 0 to 1 50%)

• Unidirection operat ion with coast-to -rest

or. stop command standard . (Dynamic brak ing

and reversing available as options .)

• 20 :1 controlled-speed range by means of armat ure voltage control.

•

\Nith Auxiliary Panel specified , armature loop contactor removes power to drive motor .

• Isolated armature voltage and current feedback decouples armatu re power from opera-

tor devices and provides additional noise immunity .

•

\Nith tachometers specified in this manual, 0.5% or 1.0% speed regulation with a 95 %

load change .

• Operates and delivers rated output speed with specified regulation tolerance limits even

with a-c line variations of± 10% of nominal rated input voltage .

Speed Regulation

• Jumper reconnectable regulator circuits which allow armature (A), counte r EMF (C) or

tachometer feedback (T) regulation .

•

\Nith voltage regulation, 3 to 5% speed regulation with 95% load change .

•

\Nith counter EMF (CEMF) regulation , 2 to 3% speed regulation with a 95 % load change .

•

\Nith tachometer specified, 1 % speed regulation with a 95% load change . (Tachometer s

are : RE-045 a-c tachometer; also

SPY or RE-020 d-c tachometer .)

•

\Nith tachometer specified, 0.5% speed regulation with 95% load change . (Tachometer is

BC42.)

User Adjustments

• Adjustable IR drop compensation (0 to 12% of rated load).

• Adjustable maximum speed (50 to 100 % of base motor speed).

• Adjustable minimum speed (up to 50% of base motor speed).

• Adjustable current limit (10 to 150 % of full-load current).

• Adjustable, separately set linear acceleration and deceleration rates (0.5 to 30 sec.).

Safety

• Control circuitry guards against automatic restarting of equipme nt after resumption of

interrupted a-c incoming power.

• Regulator and Operator's Controls isolated from a-c line for personnel protection .

• Armature voltage and current feedback isolated to assure separat ion of power and regula-

tor circuits.

Hardware

-:- Conveniently located screw terminal connections for incoming a-c and outgoing d-c power

allow easy cable entry and connection.

•

\Nith · Auxiliary Panel specified, a-c line fuses protect Power Cube from armature short

circuit and power relays provide positive power disconnect .

• Protection from momentary surges on a-c line and from d-c load transients.

5

Loading...

Loading...