The Operator Control Station AUTO / MANUAL selector

switch is used to obtain local control or master reference

control of the individual drive. When the selector switch is

placed in the AUTO mode, the individual drive SPEED

Potentiometer automatically is converted into a draw pot

adjustment for precise tFim control between drives. The

only adjustment requirement is a zero set adjustment on

the Reference Receiver Module. Should the speed refer-

ence wires become disconnected, the FlexPak Plus will go

to zero speed.

FlexPak Plus controllers controlled by Master Isolated Ref-

erence are ideally suited for non-reversing multiple con-

veyor drives, proportional pumps, feeder drives, web lines

or other similar operations which require multiple drives to

follow a common reference signal .

To install the Kit, follow these procedures.

Step 1 - Refer to Figure 6.4 and note the heavy border

area atthe extreme left-hand side of the Regulator Module.

This is the area where the Switch Receiver Module is to be

mounted. First, remove the Remote Operator Adapter

Module. Then, place the Switch Receiver Module in the

proper orientation so the two connectors are aligned over

the two sets of pins (marked GRN 28 and RED 32). Care-

fully, slowly and gently press the connectors down on the

pins until they bottom . Then, connect the black pig-tail

jumper of the Switch Receiver Module to pin 40 on the

Regulator Module. (Pin 40 is the left-hand pin of the group

marked AUTO REV.).

Step 2 - Fold the PC board over the top of the two connec-

tors so the mounting spacers fit into the mounting holes .

Step 3 - Connect the external start-stop wires (wires 189

and 288) from the external Master Isolated Reference

Transmitter to the terminal block on the Switch Receiver

Module in the controller cabinet.

Step 4 - Mount the Remote Operator Adapter Module on

top of the Switch Receiver Module and secure the two PC

boards with the two long screws provided.

NOTE : The external start -stop wires from the Master Iso-

lated Reference Transmitter (wires 189 and 288) must be

connected to the Switch Receiver Module (Refer to Step 3.)

before mounting the Remote Operator Adapter Module on

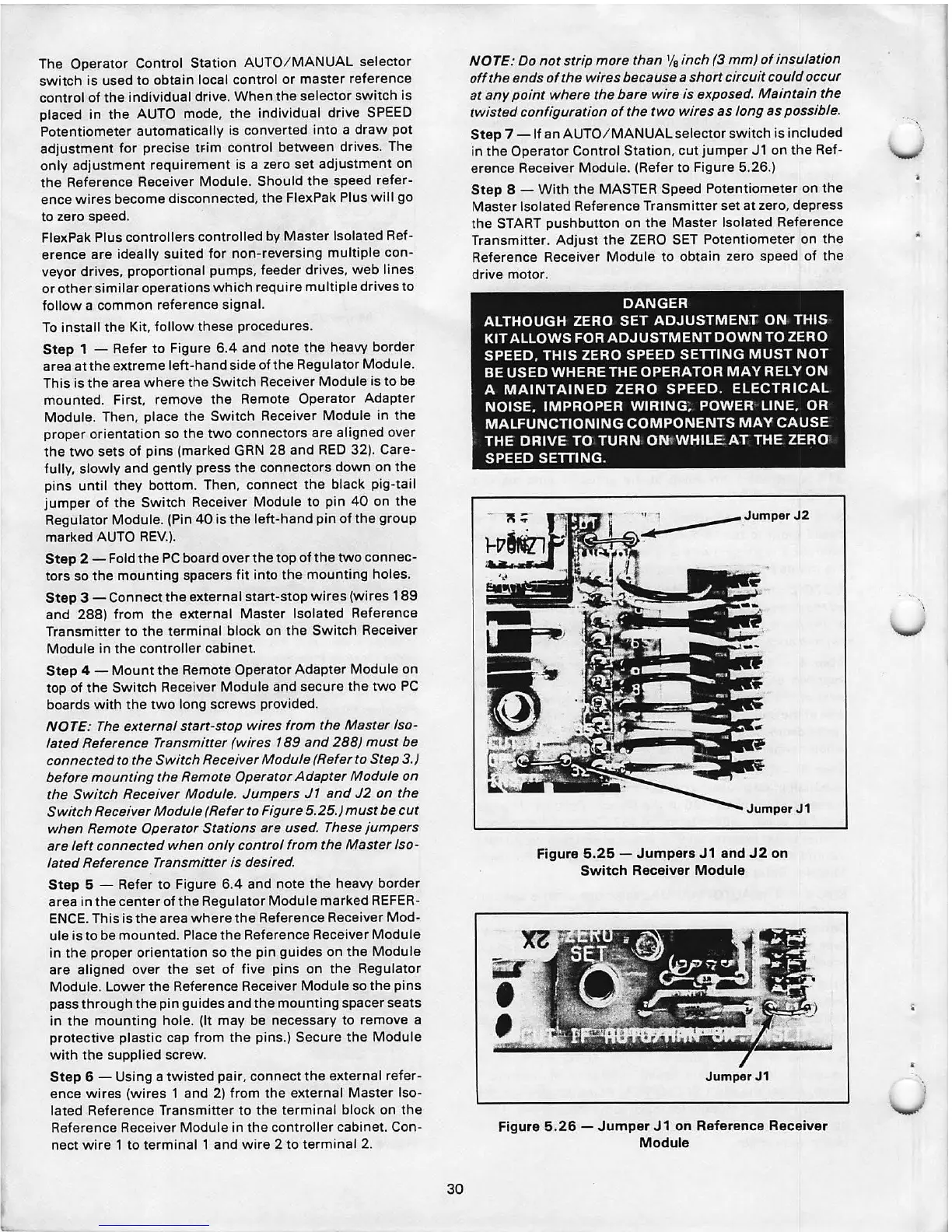

the Switch Receiver Module. Jumpers J1 and J2 on the

Switch Receiver Module (Refer to Figure 5.25.) must be .cut

when Remote Operator Stations are used. These jumpers

are left connected when only control from the Master Iso-

lated Reference Transmitter is desired.

Step 5 - Refer to Figure 6.4 and note the heavy border

area in the center of the Regulator Module marked REFER-

ENCE. This is the area where the Reference Receiver Mod-

ule is to be mounted. Place the Reference Receiver Module

in the proper orientation so the pin guides on the Module

are aligned over the set of five pins on the Regulator

Module. Lower the Reference Receiver Module so the pins

pass through the pin guides and the mounting spacer seats

in the mounting hole. (It may be necessary to remove a

protective plastic cap from the pins.) Secure the Module

with the supplied screw.

Step 6 - Using a twisted pair, connect the external refer-

ence wires (wires 1 and 2) from the external Master Iso-

lated Reference Transmitter to the terminal block on the

Reference Receiver Module in the controller cabinet. Con-

nect wire 1 to terminal 1 and wire 2 to terminal 2.

30

NOTE: Do not strip more than

1

/

8

inch (3 mm) of insulation

off the ends of the wires because a short circuit could occur

at any point where the bare wire is exposed. Maintain the

twisted configuration of the two wires as long as possible.

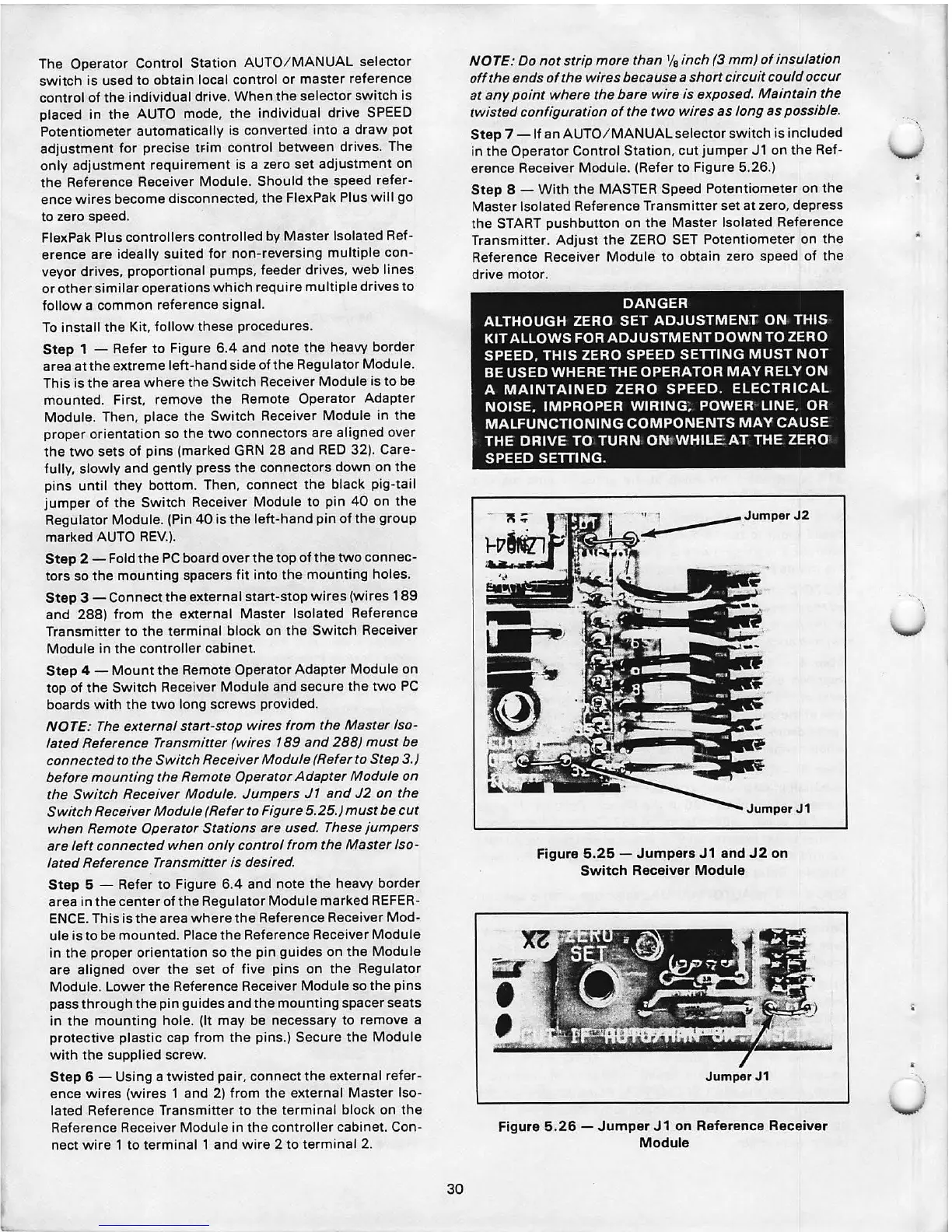

Step 7 - If an AUTO/ MANUAL selector switch is included

in the Operator Control Station, cut jumper

Jl on the Ref-

erence Receiver Module. (Refer to Figure 5.26.)

Step 8 - With the MASTER Speed Potentiometer on the

Master Isolated Reference Transmitter set at zero, depress

the START pushbutton on the Master Isolated Reference

Transmitter . Adjust the ZERO SET Potentiometer on the

Reference Receiver Module to obtain zero speed of the

drive motor.

DANGER

ALTHOUGH ZERO SET ADJUSTMENT ON THIS

KIT ALLOWS FOR ADJUSTMENT DOWN TO ZERO

SPEED. THIS ZERO SPEED SETTING MUST NOT

BE USED WHERE THE OPERATOR MAY RELY ON

A MAINTAINED ZERO SPEED. ELECTRICAL

NOISE. IMPROPER WIRING; POWER LINE, OR

MALFUNCTIONING COMPONENTS MAY CAUSE

THE DRIVE TO TURN

ONtWHILEAT THE ZERO

SPEED SETTING.

JumperJ1

Figure 5.25 - Jumpers J1 and J2 on

Switch Receiver Module

Jumper J1

Figure 5.26 - Jumper J1 on Reference Receiver

Module

\

\

Loading...

Loading...