4. OPERATION REM - GRAINVAC VR12

4.6. P

OSITIONING AND SET-UP

34 9000-00-0042 R3

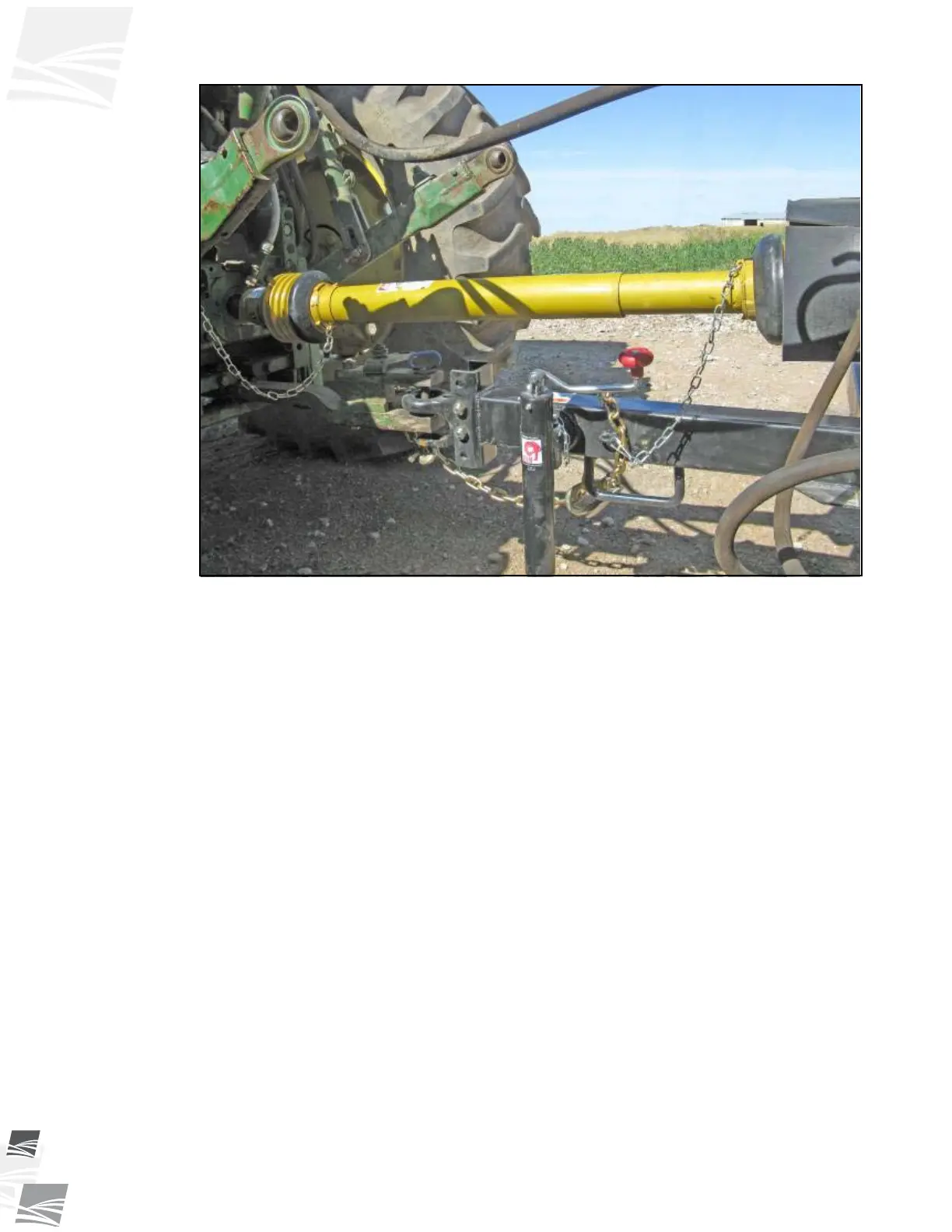

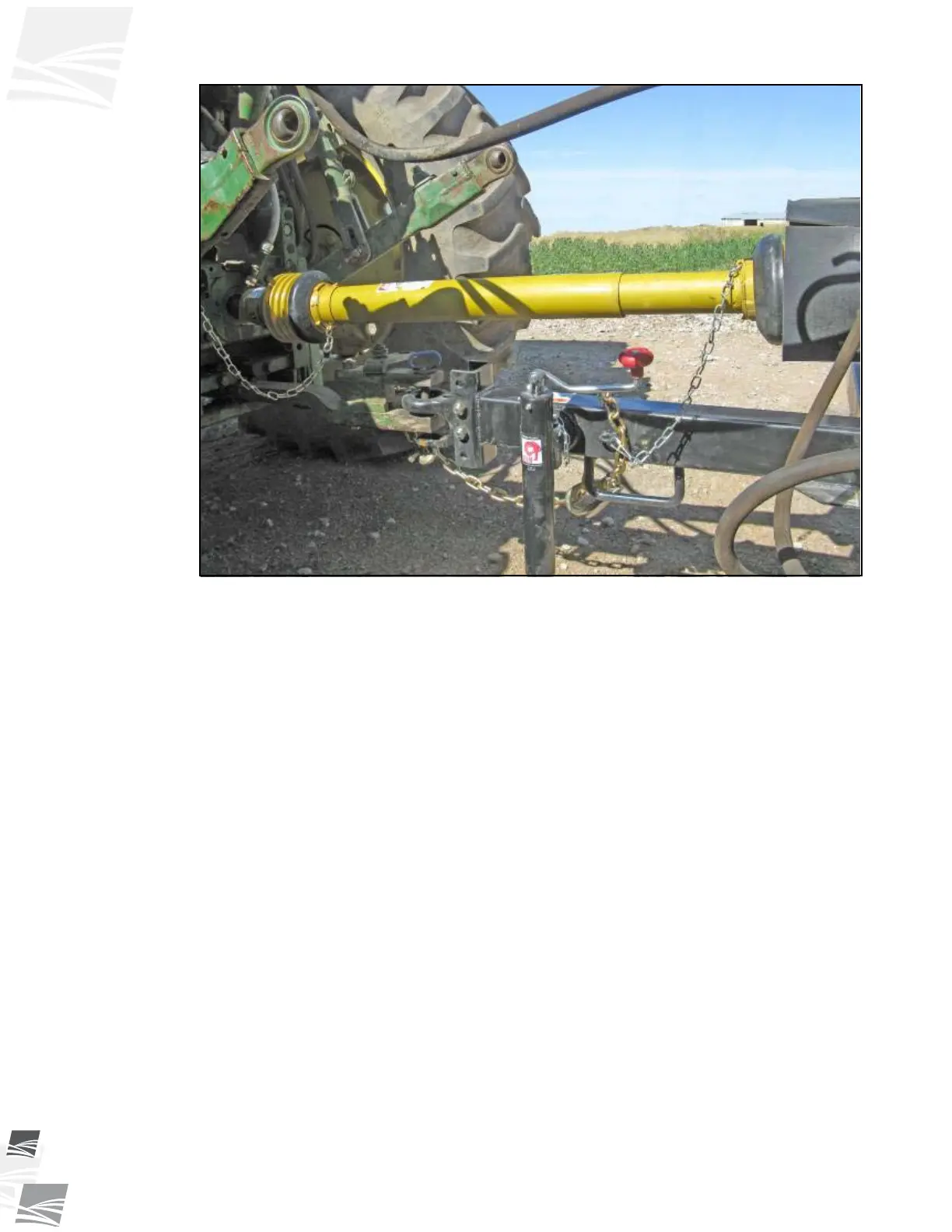

Figure 4.2 PTO Attached to Tractor

6. Attach PTO safety shield chain to a mounting point on the tractor (e.g., drawbar

cage or lift arms).

7. Assess the site while keeping in mind that a truck or grain cart must be able to easily

drive under the auger once in working position (see Figure 4.3).

a. Possible Situation #1:

• If the ground is level and the opening of the bin is within approximately 6” (152

mm) in height to that of the GrainVac inlet:

• Select the 29” (737 mm) stainless steel hose and use its over-center clamp to

attach to the aluminum bin load-out nozzle. Insert the angled end of the load-out

nozzle into the grain so that the sliding air door is not submerged and can easily

be adjusted.

b. Possible Situation #2:

• If the ground is not level and the bin door is not within 6” (152 mm) of the Grain-

Vac inlet height, or the GrainVac has to be parked at some angle to the bin open-

ing:

• Selecting as many 4’ (1219 mm) stainless steel flex hoses as necessary and

using the over-center clamps, attach the flex hoses to the aluminum load-out

nozzle. Insert the angled end of the aluminum load-out nozzle into the grain so

that the sliding air door is not submerged. Adjust the stainless steel hose(s) to

minimize sharp bends or curves. This will maximize capacity and minimize hose

wear.

Loading...

Loading...