REM - GRAINVAC VR12 5. MAINTENANCE

5.4. MAINTENANCE PROCEDURES

9000-00-0042 R3 65

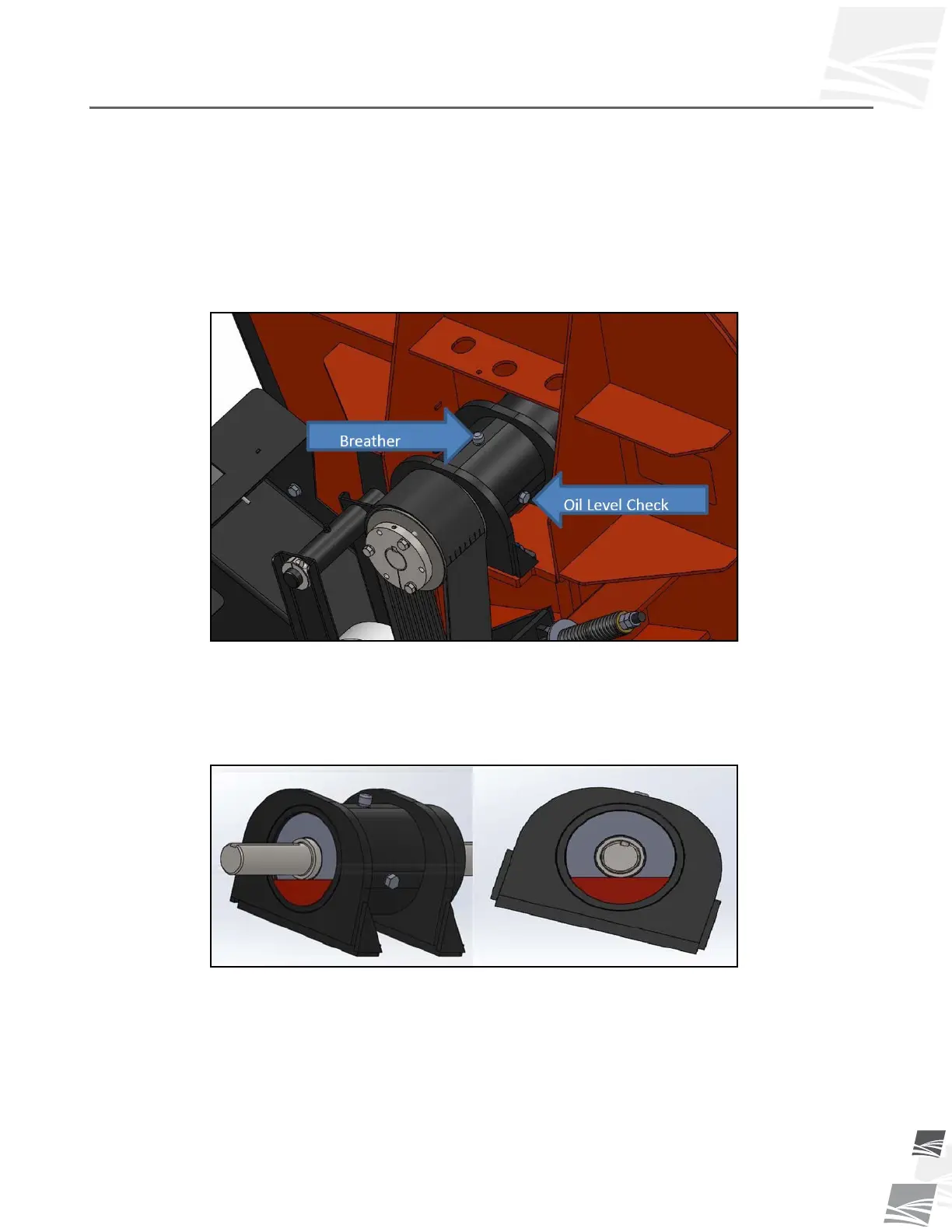

5.4.10. Rotor Bearing Cartridge Oil Bath – Checking Oil Level

Important: The oil level in the rotor bearing cartridge must be checked and maintained at the

recommended level to ensure efficient operation.

1. Place the GrainVac on a flat, even surface that will help ensure that the machine is

as level as possible.

2. Remove the hoses from the hose racks.

3. Remove the rear upper guard to gain access to the bearing cartridge.

4. Remove the oil level check plug on the side of the bearing cartridge.

Figure 5.17 Air Breather and Oil Level Check Plugs

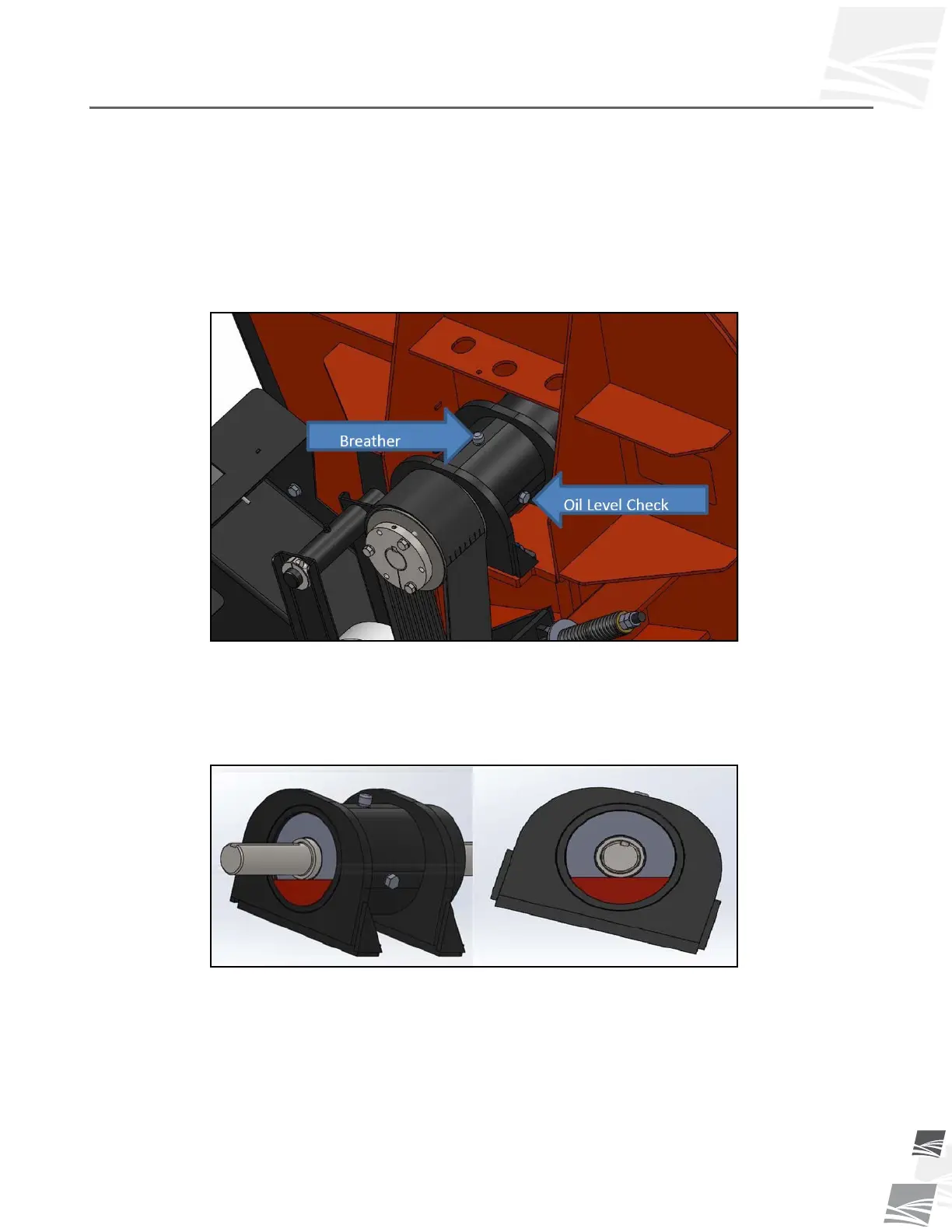

5. The oil level should come up to the lower edge of the check plug hole, which is the

correct level while the bearing cartridge is at its installed angle (see Figure 5.18). If

necessary, add oil through the breather plug hole (use SAE 75W90 synthetic gear

oil) until the correct oil level is reached.

Figure 5.18 Correct Rotor Bearing Cartridge Oil Level

6. Re-install the air breather and oil level check plugs.

Loading...

Loading...