REM - GRAINVAC VR12 8. TROUBLESHOOTING

9000-00-0042 R3 91

8. Troubleshooting

Before continuing, ensure you have completely read and understood this manual’s

Safety chapter, in addition to the safety information in the section(s) below.

The GrainVac VR12 is a simple and reliable system. However, listed below are some

possible causes and solutions to problems you may encounter with the equipment. If

you encounter a problem that is difficult to solve, even after having read this chapter,

please contact your local REM dealer or distributor. Before contacting them, please have

this operation manual and your machine’s serial number handy.

Shut down and lock out all power before maintaining, adjusting, or

unplugging the equipment.

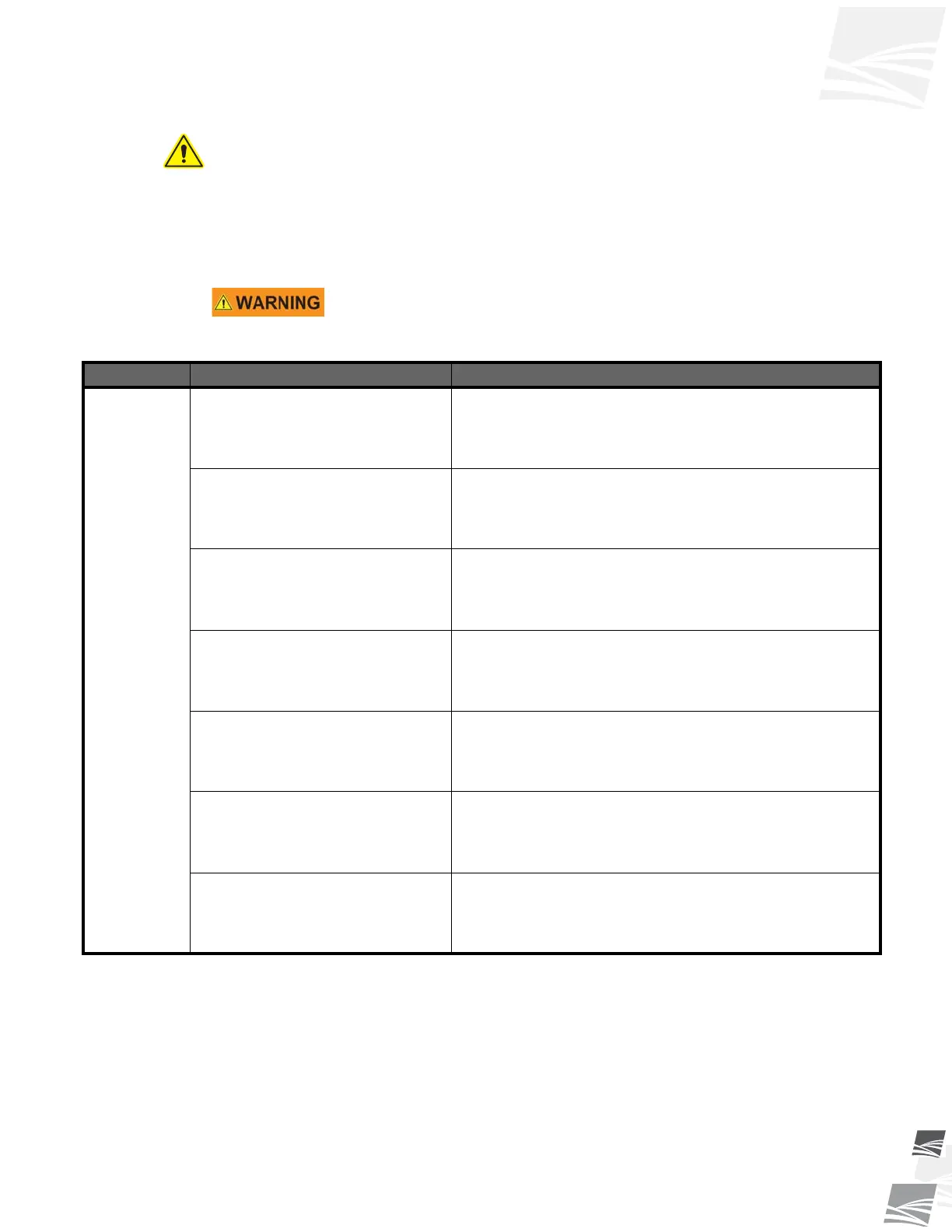

PROBLEM POSSIBLE CAUSE SOLUTION

Suction

Problems

Hose connection fitted incor-

rectly

Check all the joints in the suction tubes to ensure that

no leaks exist. Readjust the clamp(s), if necessary, to

ensure there is a tight seal on all joints. If the clamp is

damaged, it should be repaired or replaced.

Tractor not operating at proper

PTO speed

Check the PTO rpm with a hand-held digital tachome-

ter and adjust to 1000 rpm (maximum speed). Check

the Rem Tachometer to ensure it matches the hand-

held tachometer for 1000 rpm.

Steel flex hose connected incor-

rectly

Ensure the arrow indicator for flow direction (on exte-

rior of steel tube) is indicating the correct direction of

air flow. If the direction is incorrect, reverse the steel

flex hose in the hose configuration.

End dumper obstructions or

missing spring

Clean out the end dump double doors. The doors must

close completely and securely. Replace or readjust the

tension spring to the correct tension. Refer to Section

5.4.7. on page 62 for correct spring tension.

Incorrect vacuuming technique Poor suction can result from incorrect use of the

GrainVac. Review Chapter 4. Operation on page 31 to

ensure all operating instructions are being followed

accurately.

Foam rubber seals in the auger

joints are damaged and the air

seal is breached, causing air to

suction back down the auger

Replace the seals (see Figure 4.5).

Loose or slipping belts/chain Check the belt(s) for correct alignment. Tension the

belts/chain to correct tension. Replace worn belts/

chain if necessary. Refer to Chapter 5. Maintenance

(page 49) for tolerance and tension guidelines.

Loading...

Loading...