58 MAN-GD-2300-002

Calibrating the Seed Rate

There are no seed charts for the NGS hopper due to the wide range of seed purity and germination associated

with native grass seed. The only way to determine what seed rate your drill is planting is to calibrate it. Fill the

NGS hopper with seed to at least 1/3 full. The hopper should always have seed completely covering the

agitators when calibrating or planting with the drill, consider the hopper empty when the seed level reaches the

top of the agitators because the seed rate may become very inconsistent with a low seed level. You may want

to drive around with seed in the drill prior to calibrating because the seed will tend to settle and pack down in

the hopper, which will increase the seed rate.

Pick a sprocket setting based on past experience, or start with one of the middle settings. Raise the drill and

put something under the NGS seed tubes to collect the seed (a plastic tarp works well for this). When

calibrating the NGS hopper, it is recommended to catch seed from all the openers because the seed is very

light, you will have a sample large enough to accurately weigh with fewer turns of the drive wheel, and no seed

will be wasted. Disconnect the drive chains to the main hopper and the small hopper if there is seed in them

so that the calibration sample will come only from the NGS box. Use the calibration formula on page 56 of this

manual. If the seed rate is too low, go to a higher sprocket setting #; if the seed rate is high, go to a lower

sprocket setting #.

Drill Setup

Native grass seed should usually be planted shallow, 1/4-1/2” deep. To achieve this very shallow planting

depth, the frame height of the drill should be set on the high side (22-23") which will decrease the spring down

pressure on the no-till coulters and openers. The no-till coulter springs should be set just deep enough to cut

through the residue and prevent plugging. The T-handle on the opener should be set toward the front of its

travel, this will set the planting depth of the opener.

The operator must check seed placement and rate often to react to changes in seed and soil condition.

Seed Charts

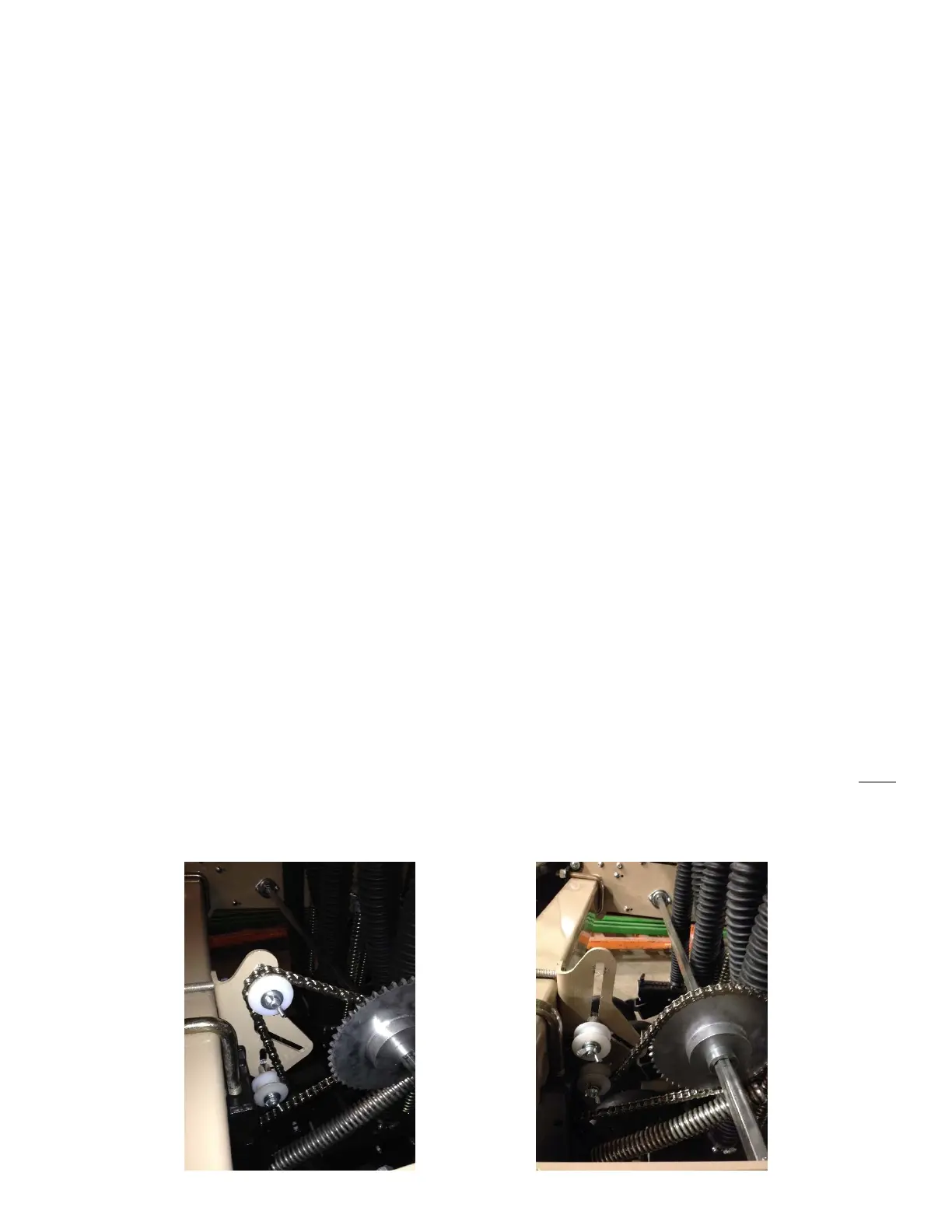

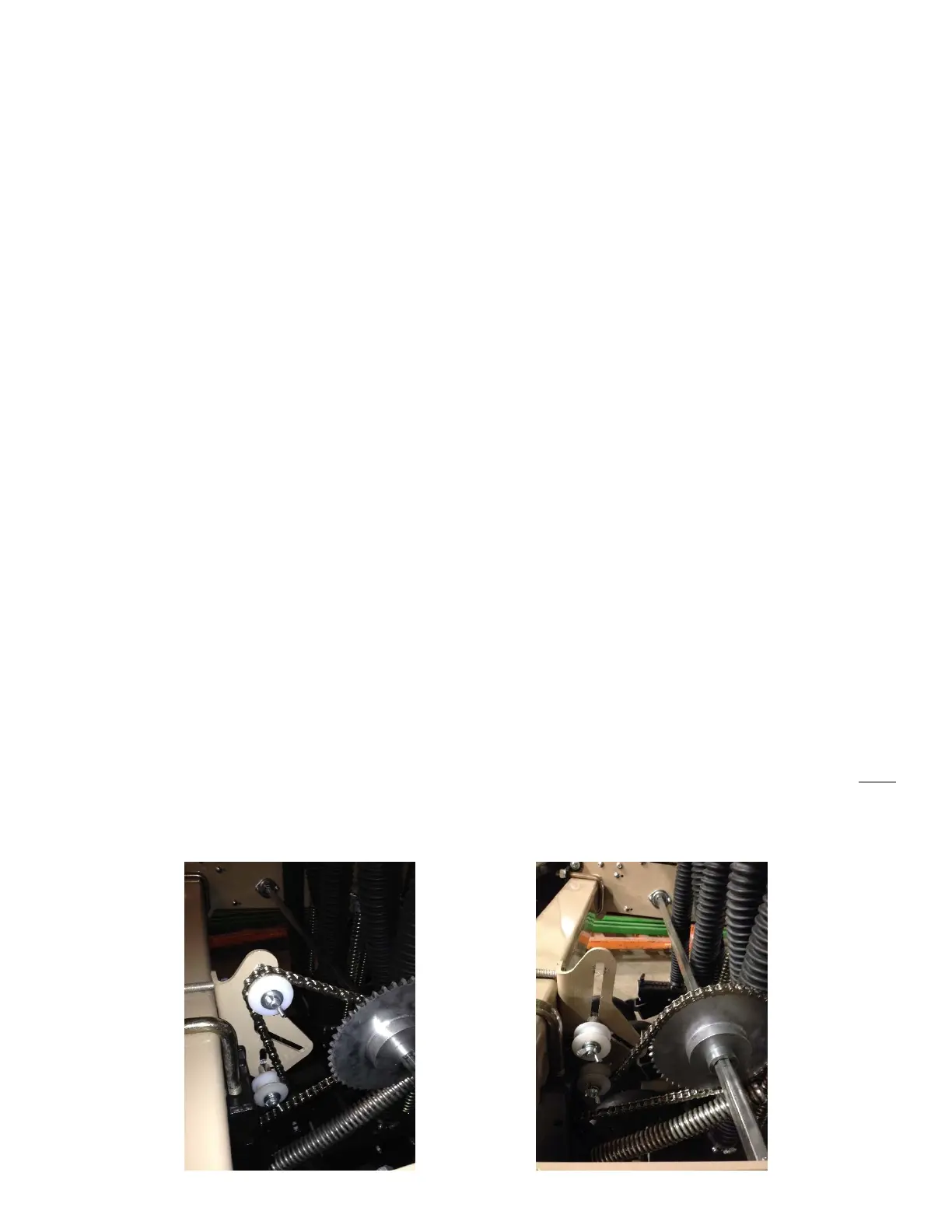

The NGS itself does not have any seed charts. To make the drill's drive system run slow enough to plant the

low seed rates typically associated with native grasses, the sprocket on the jackshaft that is run by the drive

wheel is changed from the 19-tooth (left photo) to a 48-tooth (right photo) sprocket. This sprocket change does

affect the seed charts for both the large and small seed hoppers. Do not use the seed charts in the middle of

this manual. The following seed charts (L1013 & L1014) should be used for the large and small seed hoppers

on a drill with a NGS, note the 48-tooth sprocket in the Sprocket Arrangement Drawing on the bottom of each

chart.

Loading...

Loading...